Prediction method of optical performance of polycarbonate material in dry and hot environment

An optical performance, polycarbonate technology, applied in the field of prediction of the optical performance of polymer materials, can solve the problems of shortened service life, product performance decline, polymer material deformation, etc., to achieve the effect of reducing the test workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

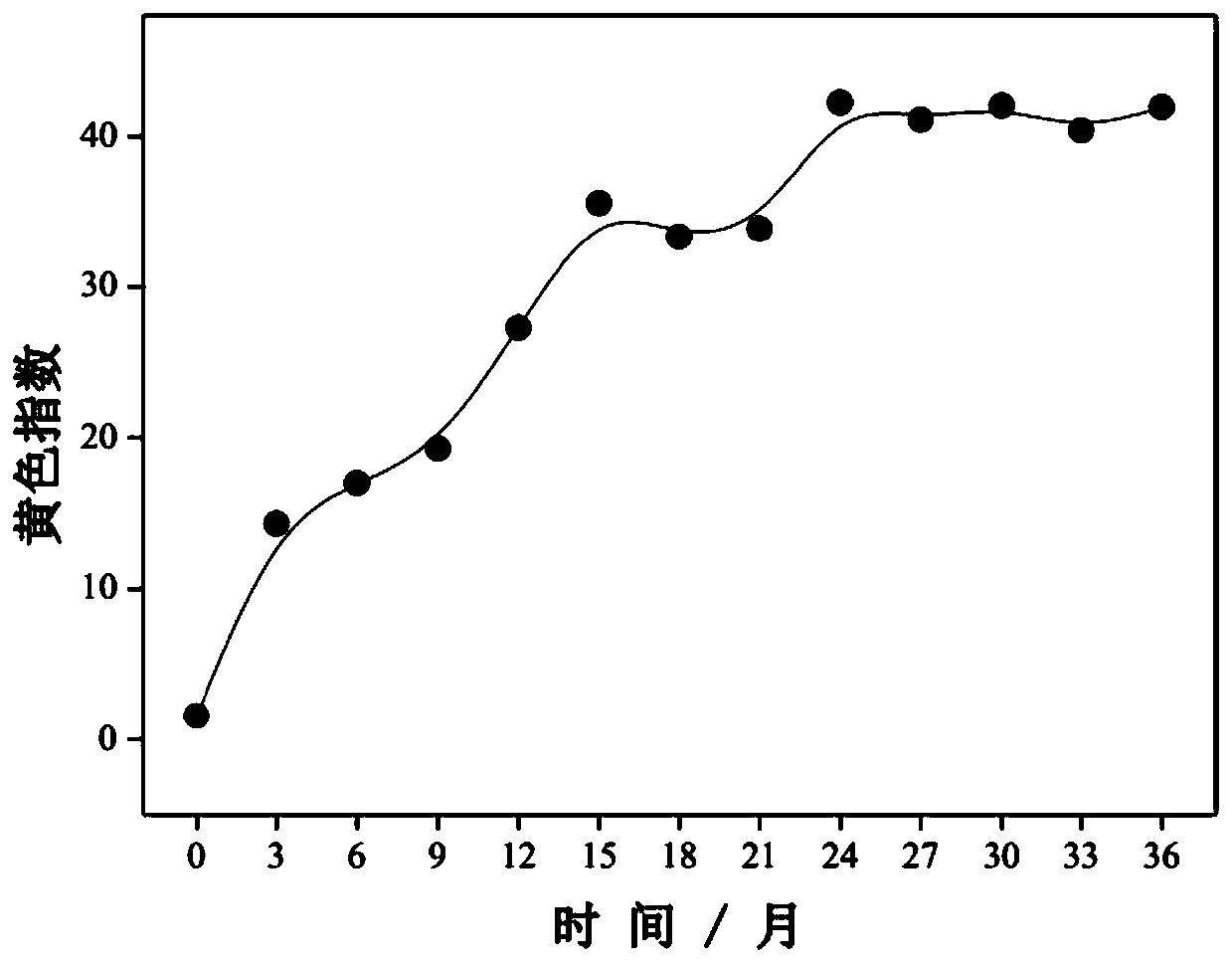

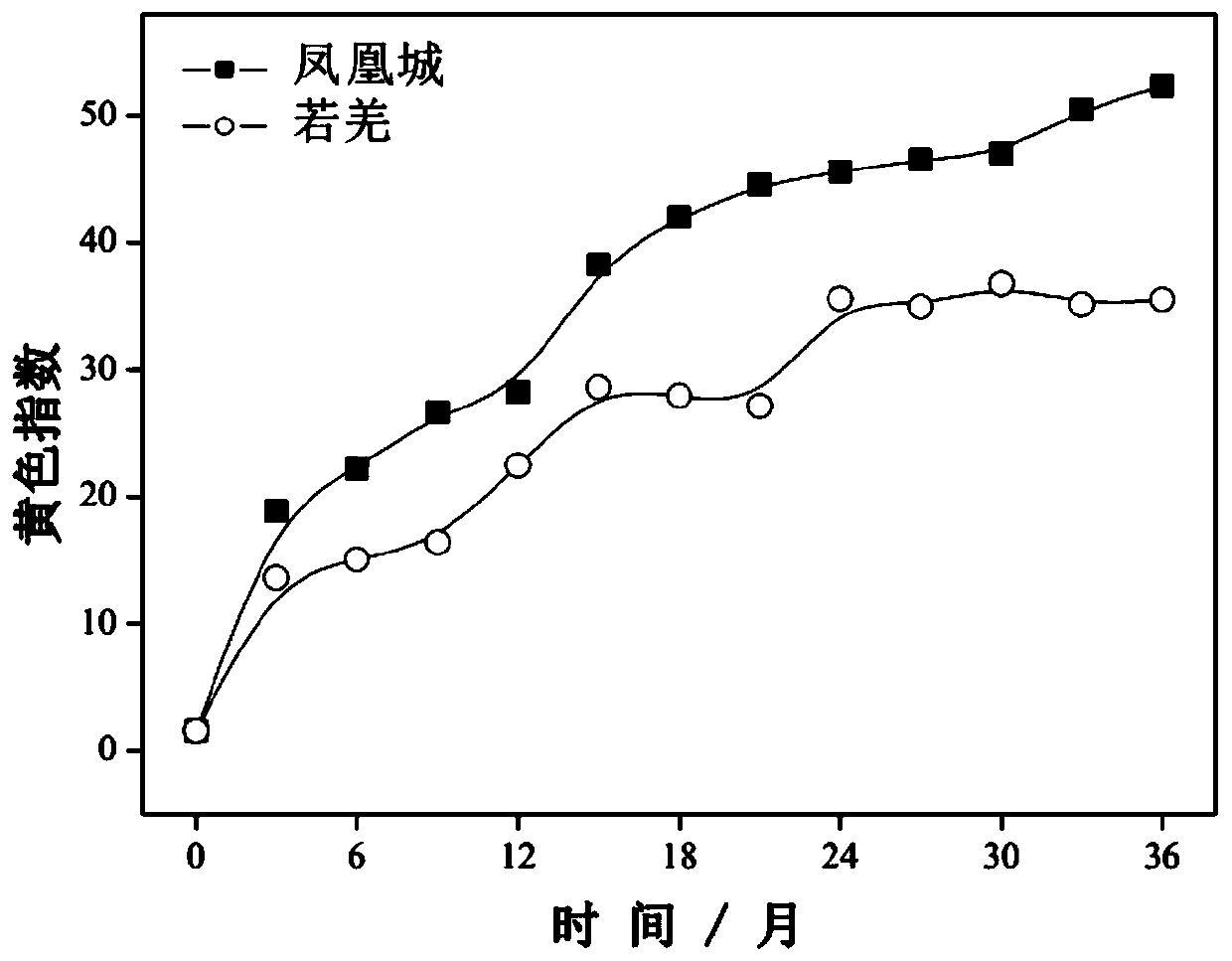

[0036] Applying the method of the present invention to predict the optical properties of PC materials in Xinjiang Turpan, U.S. Phoenix City and Xinjiang Ruoqiang, the specific steps are as follows:

[0037] (1) Prepare PC samples, prepare PC raw materials into color plates with a size of 60mm×80mm×3mm by injection molding method; test the yellowness index in the optical properties of the samples before carrying out the test, test 3 samples, and take the results many times The arithmetic mean of the test is recorded as the initial performance value of the sample, and the initial yellowness index of the PC material is 1.59;

[0038] (2) The natural aging test of PC materials was carried out in Turpan, Xinjiang, and the annual solar radiation in Turpan (I 1 ) and annual mean thermodynamic temperature (T 1 ), and get the following result:

[0039] I 1 =6993.08(MJ / m 2 )

[0040] T 1 =16.71(℃)+273.15=289.86(K)

[0041] After a 3-year natural aging test, the yellowness index o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com