Novel underground pipe rack with natural materials

An underground pipe gallery and natural material technology, applied in the field of underground construction engineering, can solve the problems of economic loss, short service life, low creep resistance, etc., to prolong service life, reduce the risk of discovery and destruction, and improve safety and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

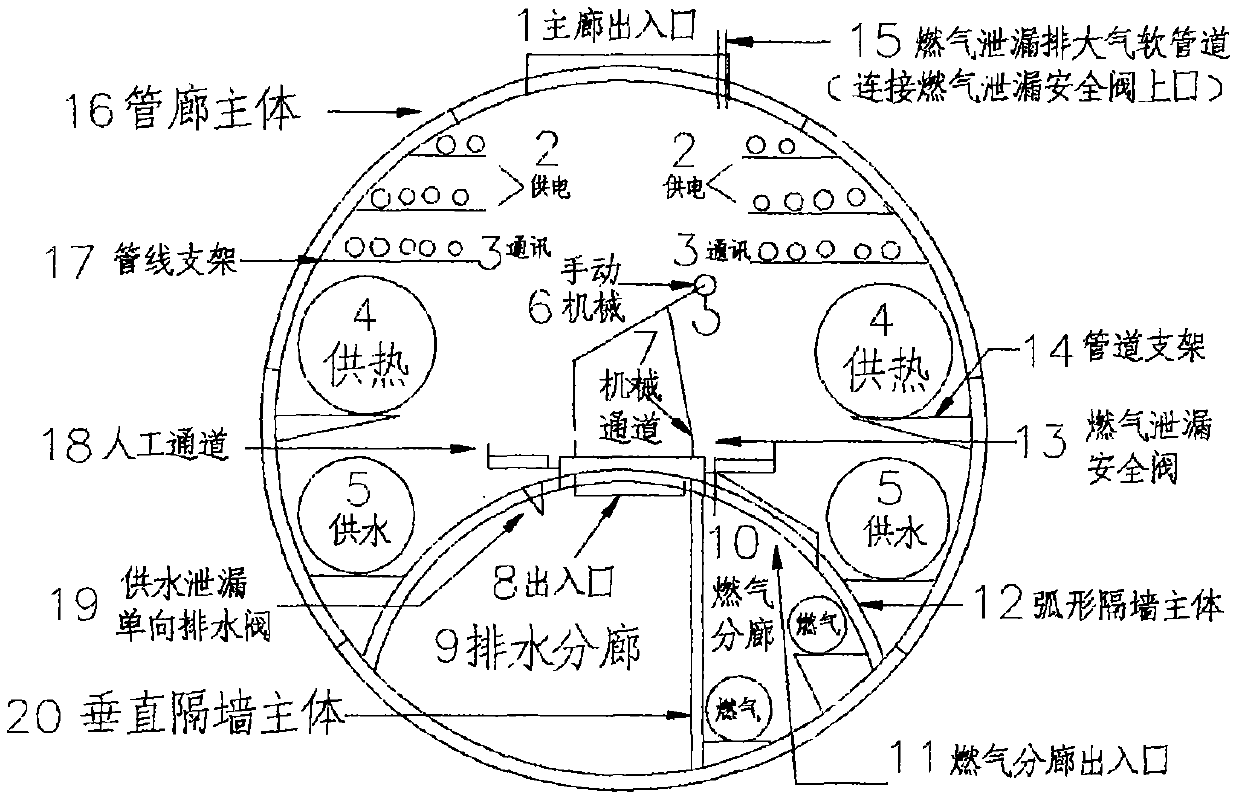

[0014] The entrance and exit of the main corridor of the underground pipe gallery (1), two sets of power pipelines (2), two sets of communication pipelines (3), two heating pipes (4), and two water supply pipes ( 5) There are several manual machines (6) on the mechanical passage of the main corridor, manual mechanical passages (7) are provided on the upper part of the drainage corridor, and the maintenance entrance and exit of the drainage corridor (8) are arranged directly above the arc-shaped isolation body. The lower left part of the body is provided with a drainage gallery (9), the lower part of the entrance and exit of the gas gallery is provided with a gas gallery and two gas pipelines (10), and the upper right part of the arc-shaped isolation body is provided with a gas gallery maintenance entrance (11). The main body of the corridor isolation body (12), the gas leakage safety valve (13) is provided on the top of the gas branch corridor, the pipe support (14) is provid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap