Coating process of Oxford fabric polyurethane coating fabric

A coating process, the technology of unglue, which is applied in the direction of textiles and paper making, can solve the problems of inability to form a good fixed shape, insufficient elasticity and water resistance of the fabric, complex process, etc., and achieve high smoothness, good effect and structural strength big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment discloses a coating process for Oxford cloth unglue coated fabrics, comprising the following steps:

[0057] S1: Lay Oxford cloth flat, fix the four corners, and clean with hot air;

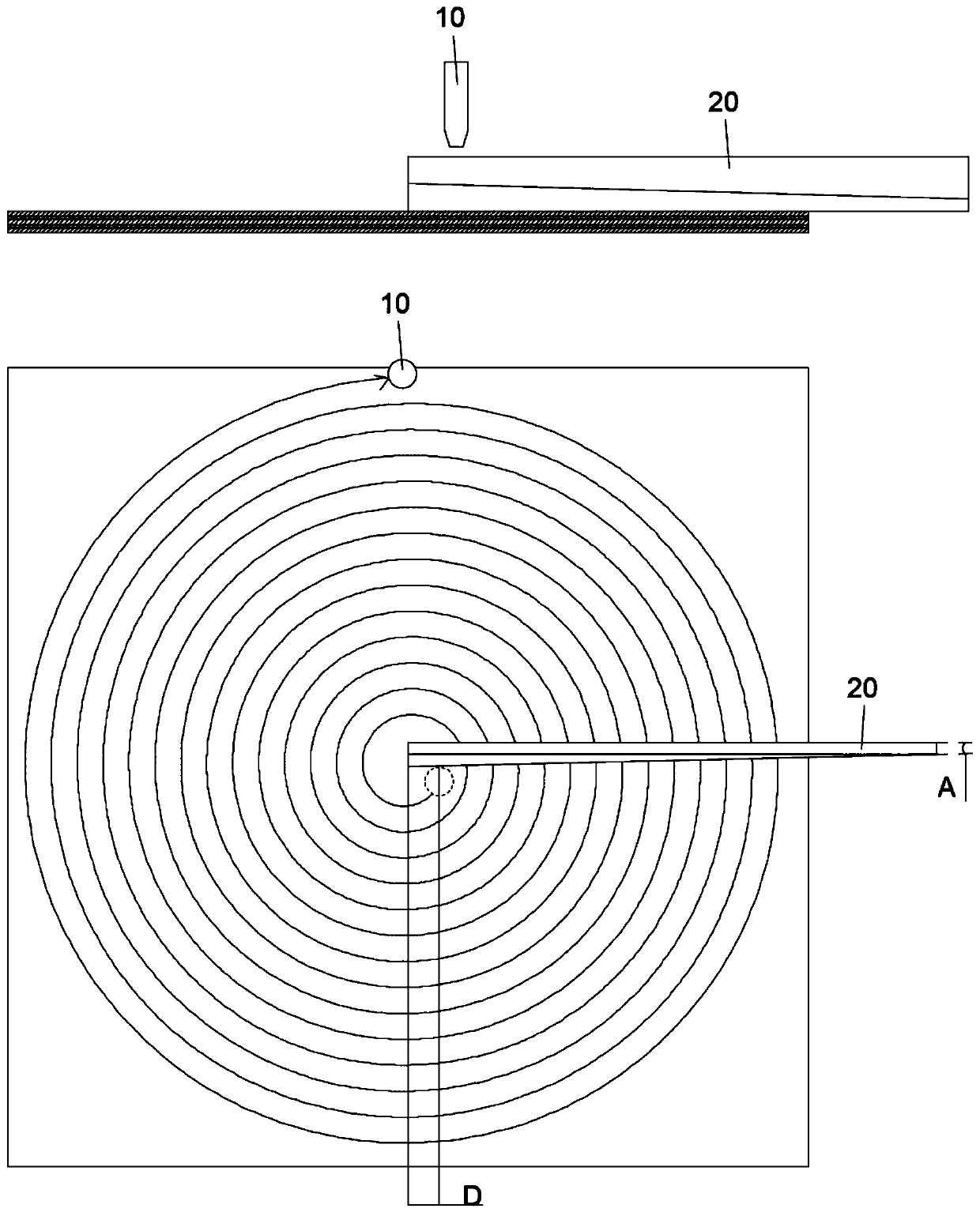

[0058]S2: Use the nozzle to spray the tackifier on the surface of the Oxford cloth in a spiral shape from the inside to the outside. At the same time, use the inclined scraper to scrape off the tackifier following the rotation of the nozzle. The rotation speed is 2-5r / s, and the thickness of the tackifier is 0.1mm~0.5mm;

[0059] S3: Melt the glue, use the nozzle to spray the glue on the surface of the Oxford cloth in a spiral shape from the inside to the outside, and use a beveled scraper to scrape the glue with the rotation speed of 4~7r / s, following the rotation of the nozzle. The temperature of the unglue is kept at 180-190°C, and the thickness of the unglue is 0.3-1mm;

[0060] S4: After scraping, let it stand for 2-3 hours, and wait for the glue to dry;

[0061] S5...

Embodiment 2

[0067] This embodiment discloses a coating process for Oxford cloth unglue coated fabrics, comprising the following steps:

[0068] S1: Lay Oxford cloth flat, fix the four corners, and clean with hot air;

[0069] S2: Use the nozzle to spray the tackifier on the surface of the Oxford cloth in a spiral shape from the inside to the outside. At the same time, use the inclined scraper to scrape off the tackifier following the rotation of the nozzle. The rotation speed is 2-5r / s, and the thickness of the tackifier is 0.3mm;

[0070] S3: Melt the glue, use the nozzle to spray the glue on the surface of the Oxford cloth in a spiral shape from the inside to the outside, and use a beveled scraper to scrape the glue with the rotation speed of 4~7r / s, following the rotation of the nozzle. The temperature of the unglue is kept at 180-190°C, and the thickness of the unglue is 0.7mm;

[0071] S4: After scraping, let it stand for 2-3 hours, and wait for the glue to dry;

[0072] S5: Turn ...

Embodiment 3

[0078] This embodiment discloses a coating process for Oxford cloth unglue coated fabrics, comprising the following steps:

[0079] S1: Lay Oxford cloth flat, fix the four corners, and clean with hot air;

[0080] S2: Use the nozzle to spray the tackifier on the surface of the Oxford cloth in a spiral shape from the inside to the outside, and at the same time use a beveled scraper to scrape off the tackifier following the rotation of the nozzle, the rotation speed is 3.5r / s, and the thickness of the tackifier is 0.1 mm~0.5mm;

[0081] S3: Melt the glue, spray the glue on the surface of the Oxford cloth in a spiral shape from the inside to the outside with the nozzle, and use the inclined scraper to scrape the glue with the rotation speed of 5.5r / s. The temperature of the glue is kept at 185°C, and the thickness of the glue is 0.3-1mm;

[0082] S4: After smoothing, let it stand for 2.5H, and wait for the Uliglue to dry;

[0083] S5: Turn the Oxford cloth over so that the sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com