Hydrophobic edible preservative film and preparation method thereof

A hydrophobic, fresh-keeping film technology, applied in the field of food packaging, can solve the problems of deterioration, easy water absorption and mechanical properties, and achieve the effects of enhanced hydrophobic performance, good biocompatibility and degradability, as well as fresh-keeping performance and strong binding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

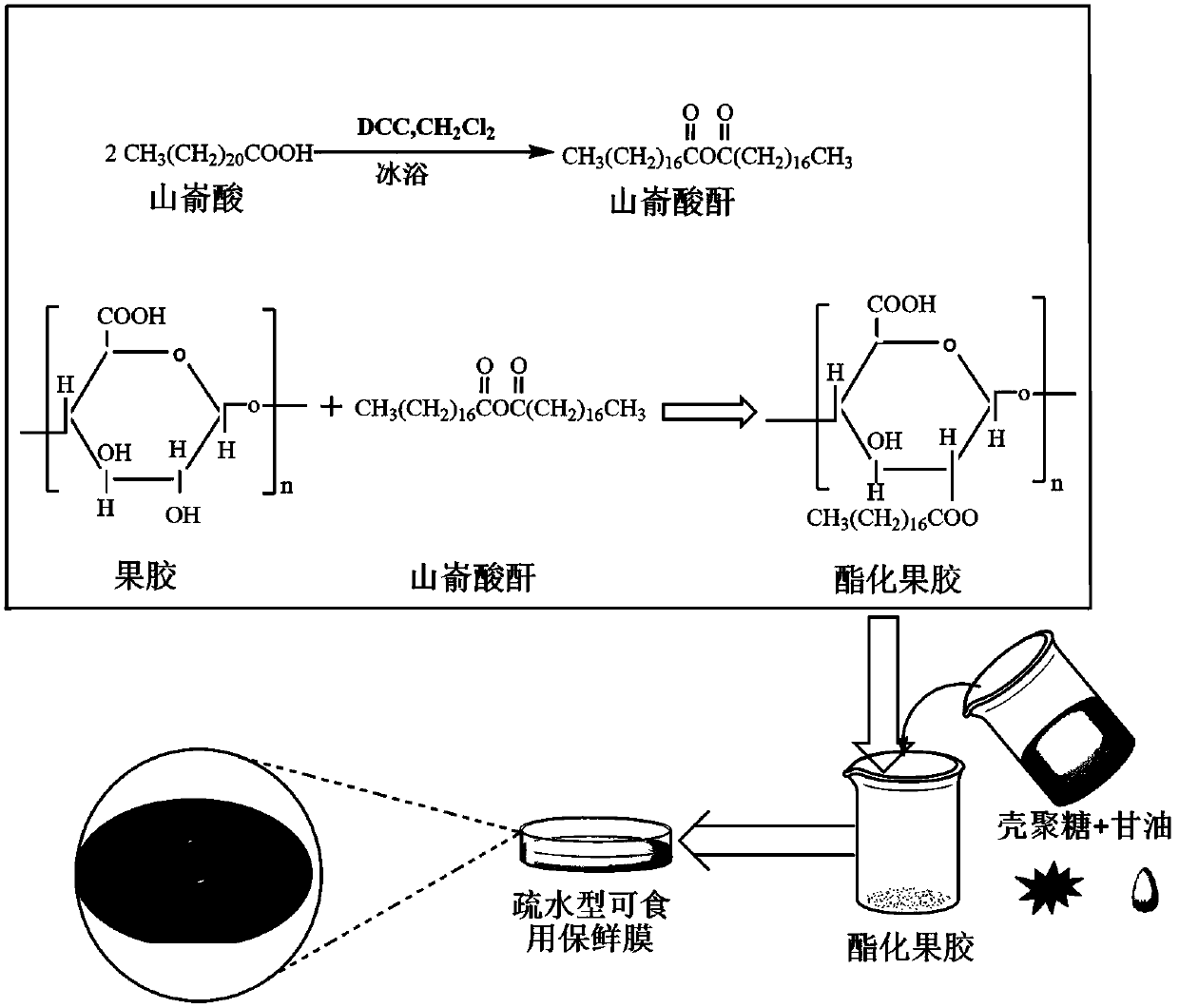

[0025] The present invention also provides the hydrophobic edible fresh-keeping film and its preparation method, comprising the following steps.

[0026] 1) Dissolve 30-60 parts of behenic acid in 200 parts of dichloromethane solution, and stir the solution in an ice-water bath.

[0027] 2) Dissolve 15-30 parts of dicyclohexylcarbodiimide in 100 parts of dichloromethane, and add it to the solution described in step 1), and stir in an ice-water bath for 2-4 h.

[0028] 3) Filter the mixed solution to remove the white solid residue (dicyclohexylurea), and collect the filtrate.

[0029] 4) Add 10-20 parts of low-methoxyl pectin and 2-4 parts of potassium carbonate to the filtrate collected in step 3), stir and heat in a water bath at 60-90 °C for 2-4 h, and then concentrate the filtrate by rotary evaporation , followed by freeze-drying the concentrated solution to collect the powdery substance, namely behenate pectin.

[0030] 5) Add 15-30 parts of chitosan to 500 parts of deio...

Embodiment 1

[0035] A hydrophobic edible plastic wrap and a preparation method thereof, which is prepared from the following raw materials in parts by weight:

[0036] Behenate pectin 45 parts

[0037] Chitosan 20 parts

[0038] Glycerin 15 parts

[0039] acetic acid 5 parts

[0040] Wherein the behenate pectin is prepared from the following raw materials in parts by weight:

[0041] 45 parts behenic acid

[0042] Dicyclohexylcarbodiimide 20 parts

[0043] Low methoxyl pectin 15 parts

[0044] Potassium carbonate 3 parts

[0045] The present invention also provides the hydrophobic edible fresh-keeping film and its preparation method, comprising the following steps.

[0046] 1) Dissolve 40 parts of behenic acid in 200 parts of dichloromethane solution, and stir the solution in an ice-water bath.

[0047] 2) Dissolve 20 parts of dicyclohexylcarbodiimide in 100 parts of dichloromethane, add to the solution in step 1), and stir in an ice-water bath for 3 h.

[0048] 3) Filter the mixe...

Embodiment 2

[0055] A hydrophobic edible plastic wrap and a preparation method thereof, which is prepared from the following raw materials in parts by weight:

[0056] Behenate pectin 45 parts

[0057] Chitosan 20 parts

[0058] Glycerin 10 parts

[0059]acetic acid 5 parts

[0060] Wherein the behenate pectin is prepared from the following raw materials in parts by weight:

[0061] 45 parts behenic acid

[0062] Dicyclohexylcarbodiimide 20 parts

[0063] Low methoxyl pectin 15 parts

[0064] Potassium carbonate 3 parts

[0065] Concrete preparation method is with embodiment 1.

[0066] In this example, the amount of added glycerin is low, and the tensile strength of the composite film is high, but the toughness is very poor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com