A kind of black ink-jet ceramic brick and its manufacturing method

A manufacturing method and technology of ceramic tiles, which are applied in the field of black inkjet ceramic tiles and its manufacture, to achieve the effects of accelerating drying, improving drying efficiency, and increasing moisture transpiration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

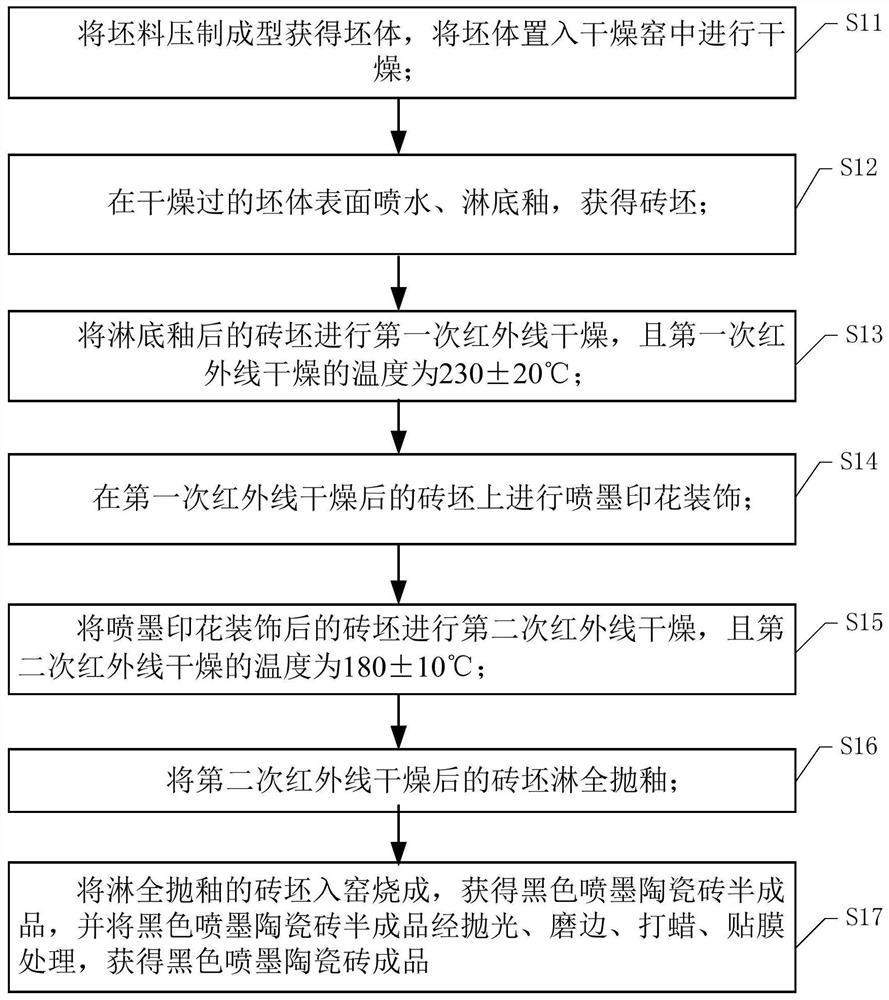

[0075] see figure 1 , a method for manufacturing black inkjet ceramic tiles is provided in the present embodiment, comprising:

[0076] Step S11, pressing the blank to obtain a green body, and putting the green body into a drying kiln for drying;

[0077] Step S12, spraying water on the surface of the dried body and pouring the bottom glaze to obtain the brick body;

[0078] Step S13, drying the adobe after the primer glaze for the first time by infrared drying, and the temperature of the first infrared drying is 230±20°C;

[0079] Step S14, performing inkjet printing decoration on the adobe after the first infrared drying;

[0080] Step S15, drying the adobe decorated by inkjet printing for a second time with infrared rays, and the temperature of the second time for infrared drying is 180±10°C;

[0081] Step S16, fully glaze the adobe after the second infrared drying;

[0082] Step S17, firing the fully glazed tiles in a kiln to obtain semi-finished black inkjet ceramic til...

Embodiment 2

[0085] This embodiment provides a method for manufacturing black inkjet ceramic tiles, which is different from the method for manufacturing black inkjet ceramic tiles provided in Embodiment 1 in that the surface temperature of the green body after drying in step S11 is 85±5°C.

[0086] It can be understood that by controlling the drying temperature of the green body, the stability of the glaze absorption speed of the green body can be effectively controlled, and the ink penetration speed during inkjet printing can be ensured, thereby effectively avoiding deviations in the color development ability of the ink and avoiding black spraying. Ink ceramic tiles appear chromatic aberration.

Embodiment 3

[0088] This embodiment provides a method for manufacturing black inkjet ceramic tiles, which differs from the method for manufacturing black inkjet ceramic tiles provided in Embodiment 1 in that the amount of water sprayed on the green body in step S12 is 78± 2g / m 2 .

[0089] It can be understood that by controlling the amount of water sprayed on the green body, the problems of pinholes when glaze is poured on the green body and slow penetration of ink during inkjet printing to avoid glaze defects can be effectively avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com