Low-cost batch preparation method and system of multi-material and multi-structure mid-infrared optical fiber

An infrared light and multi-material technology, which is applied in the low-cost batch preparation of mid-infrared optical fibers and the low-cost batch preparation of mid-infrared low-loss optical fibers, can solve the problems of uncontrollable core-cladding ratio, core-clad interface defects, and single structure, etc. problem, to achieve the effect of good core clad interface, reduce the amount of glass, and reduce the volume of the lower end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A batch preparation method of a multi-material and multi-structure mid-infrared optical fiber provided by the present invention comprises the following steps:

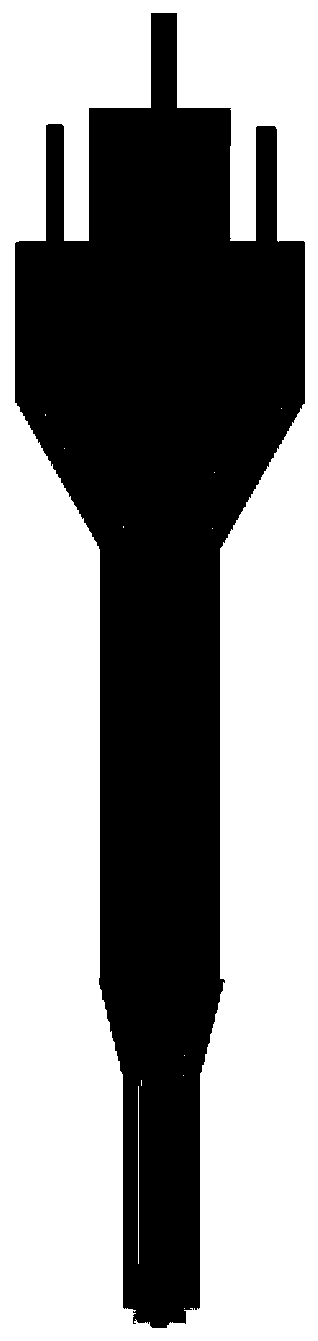

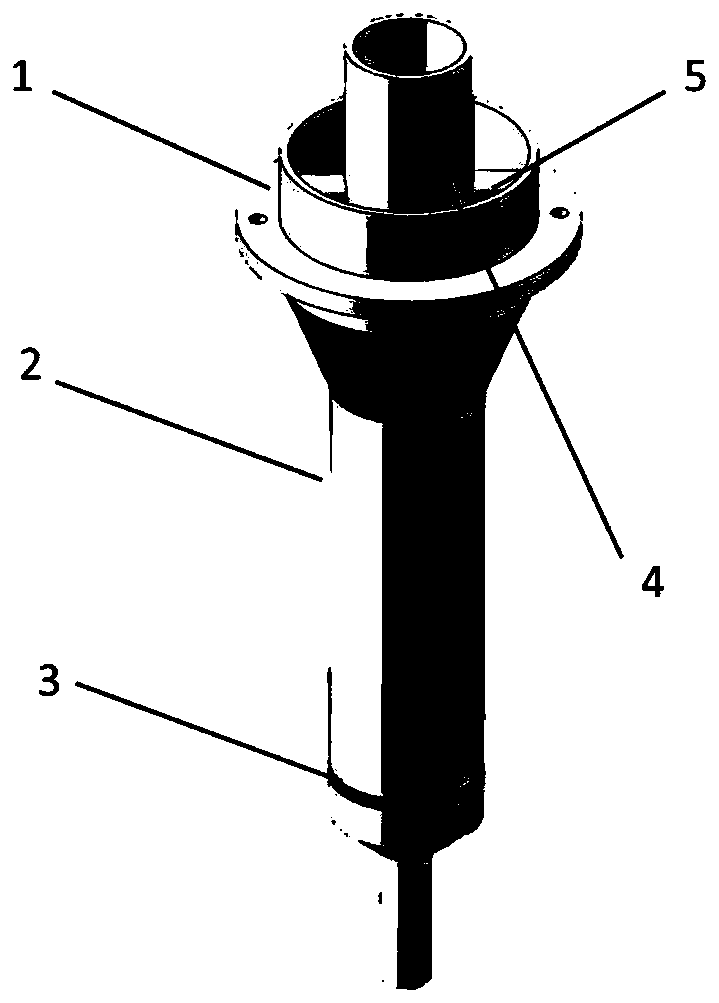

[0053] (1) The initial mid-infrared optical fiber preform with a core-clad structure is prepared by a double-crucible method;

[0054] (2) The polymer film is wound on the outer surface of the initial mid-infrared optical fiber preform obtained in step (1) by the film winding method, and after vacuum curing, a glass core layer, a glass cladding layer and a polymer cladding layer are obtained in sequence from the inside to the outside. Multi-layer mid-infrared optical fiber preform;

[0055] (3) Thermally drawing the multi-material and multi-structure mid-infrared optical fiber preform obtained in step (2) to obtain the multi-material mid-infrared optical fiber.

[0056] In some embodiments, step (1) includes the following sub-steps:

[0057] (1-1) Fill the granular high-refractive-index glass and granular low-...

Embodiment 2

[0113] Embodiment 2 of the present invention provides a method for preparing a multi-material, multi-structure, low-loss mid-infrared optical fiber based on a new type of double crucible, including: making an initial preform from a double crucible, and making a multi-material, multi-structure mid-infrared optical fiber by a high-performance polymer film winding method Multi-material and multi-structure low-loss mid-infrared optical fiber prepared by preform and hot drawing method.

[0114] (1) Initial preform made of double crucibles

[0115] Chalcogenide glass As in an agate mortar 3 S 7 with As 35 S 65 Grind into granular state, separate the As 35 S 65 with As 3 S 7 Fill the inner crucible and the outer crucible, and select the vacuum fitting interface matching the new double crucible, and use flange sealing to seal the top of the new double crucible with two kinds of chalcogenide glass materials, As 3 S 7 The glass charge is 1000g, As 35 S 65 The glass charge is ...

Embodiment 3

[0121] Embodiment 3 of the present invention provides a method for preparing a multi-material, multi-structure, low-loss mid-infrared optical fiber based on a new type of double crucible, including: making an initial preform rod from a double crucible, and manufacturing a multi-material, multi-structure mid-infrared optical fiber by a high-performance polymer film winding method Multi-material and multi-structure low-loss mid-infrared optical fiber prepared by preform and hot drawing method.

[0122] (1) Initial preform made of double crucibles

[0123] Using an agate mortar, the chalcogenide glass Ge 20 As 20 Se 15 Te 45 with Ge 20 As 20 Se 18 Te 42 Grind into granular state, separate the Ge 20 As 20 Se 15 Te 45 with Ge 20 As 20 Se 18 Te 42 Fill the inner crucible and the outer crucible, and select the vacuum fitting interface matching the new double crucible, and use flange sealing to seal the top of the new double crucible with two kinds of chalcogenide glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com