Pipeline inner wall dredging device

A technology for unblocking devices and pipes, which is applied to chemical instruments and methods, cleaning hollow objects, cleaning methods and utensils, etc. It can solve the problems that the device cannot be cleaned, internal attachments cannot be cleaned, and it is prone to jamming, etc., to achieve Guaranteed flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

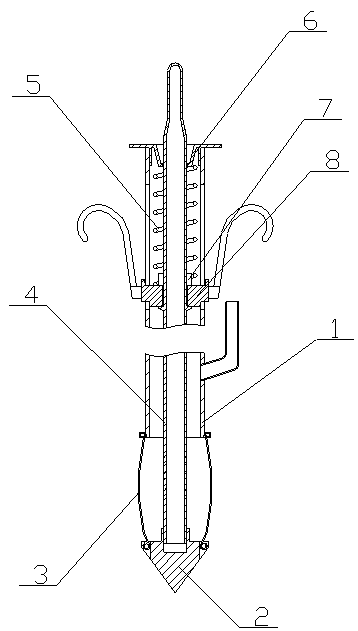

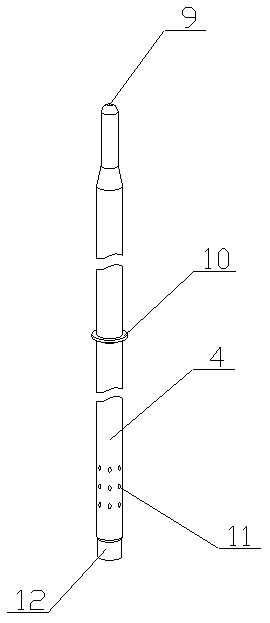

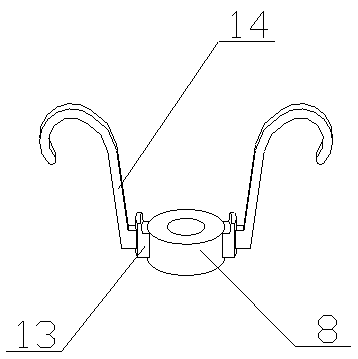

[0018] A pipe inner wall dredger of the present invention is realized in this way, consisting of a main body pipe (1), an introduction head (2), an expansion shrapnel (3), an inner air pipe (4), a compression spring (5), and a fixed end cover (6) , compression ring (7), sliding ring (8), air intake hole (9), limit ring (10), air injection hole (11), spiral tube (12), sliding block (13), handle (14 ), sliding groove (15), installation platform (16) and auxiliary flow pipe (17), the inner air pipe (4) is placed in the main pipe (1), and the two ends of the inner air pipe (4) are separated from the main pipe (1 ) from the inside to the outside, the spiral tube (12) is connected to the bottom end of the inner trachea (4), the introduction head (2) is placed on the spiral tube (12), and the top middle of the introduction head (2) is placed with The installation sleeve, and the installation sleeve and the screw tube (12) are screwed together, the introduction head (2) is a conical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com