A kind of production method of paper diaper with buffer zone

A production method and technology of diapers, applied in bandages, medical science, absorbent pads, etc., can solve problems such as leakage, poor adhesion of diaper waist circumference, etc., achieve simple process, reduce production costs, and increase air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0029] Embodiments of the invention are:

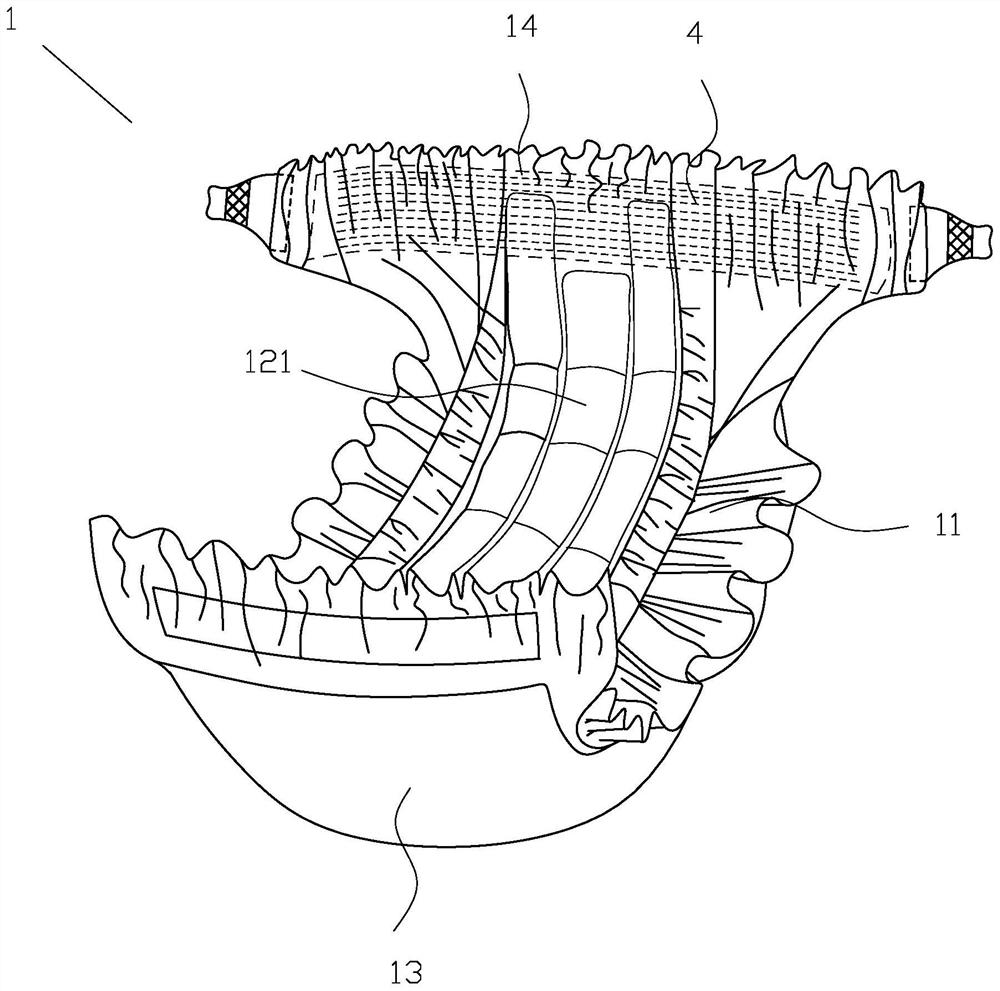

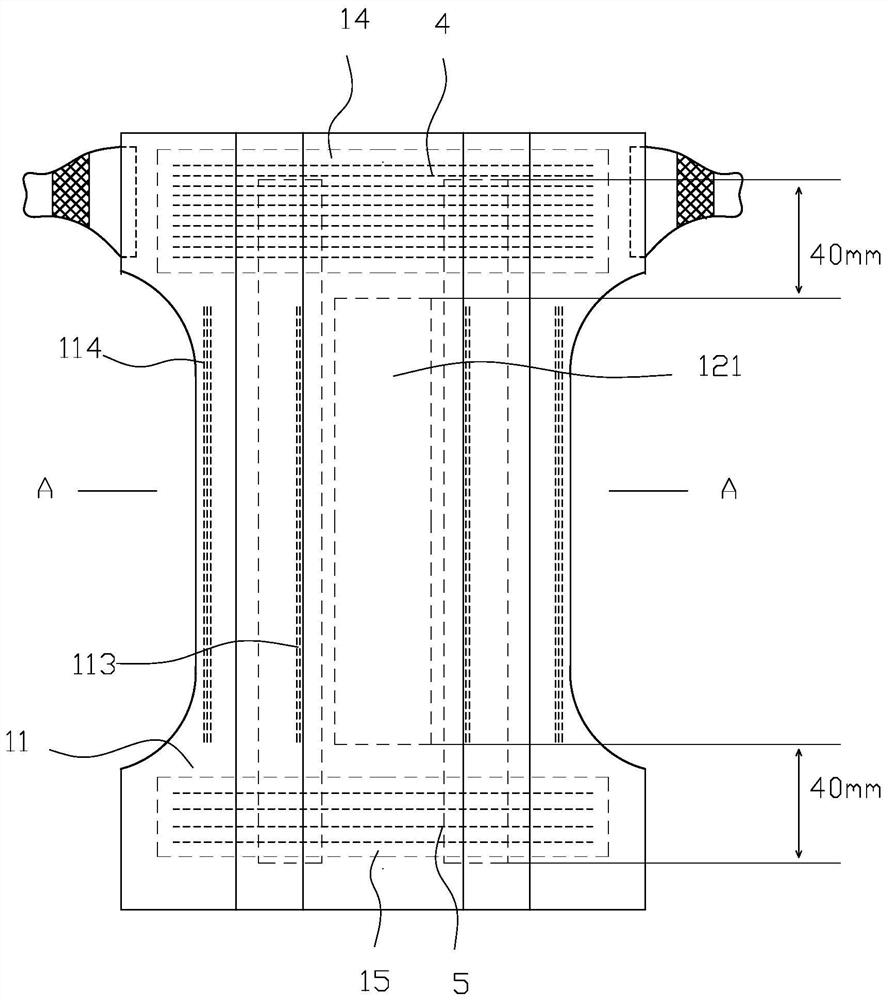

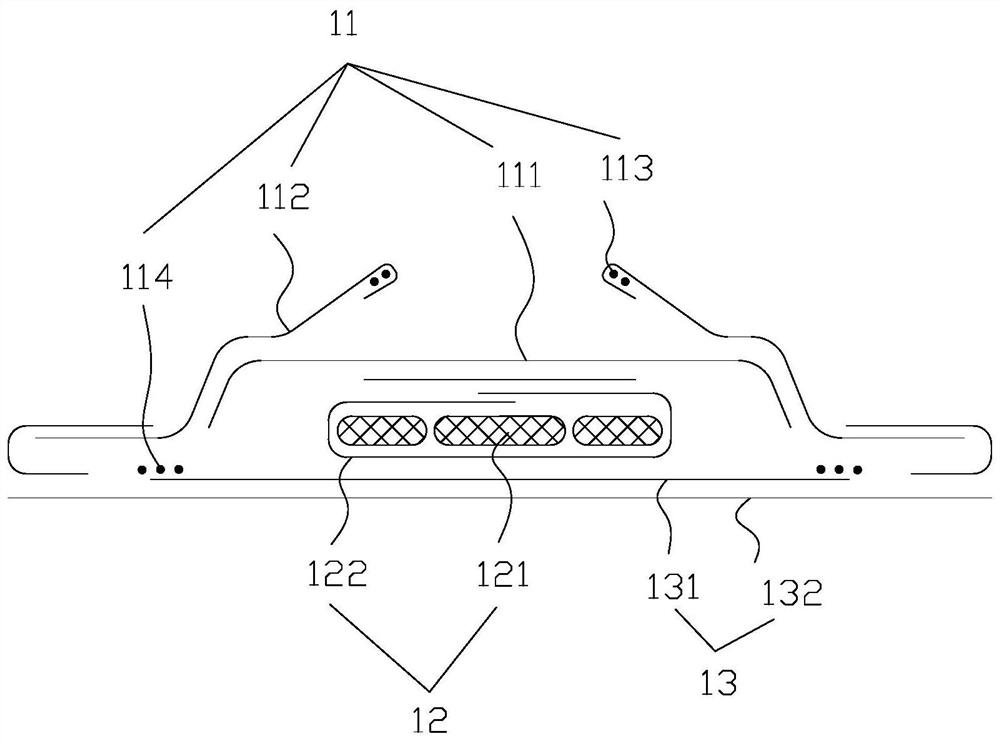

[0030] refer to figure 1 , figure 2 , image 3 and Figure 4 , a production method of diapers with a buffer zone, comprising a diaper body 1, defined as a longitudinal direction along the length direction of the diaper body 1, and a transverse direction along its width direction, the production method of the diaper body 1 is as follows:

[0031] 1), prepare the liquid-permeable surface layer 11: the liquid-permeable surface layer 11 includes a hydrophilic non-woven fabric 111 and a hydrophobic non-woven fabric 112 fixed on the lateral sides of the hydrophilic non-woven fabric 111, the hydrophilic non-woven fabric 112 The cloth 111 is adhered to the upper surface of the absorbent core 12 and is folded downwards to cover the lateral sides of the absorbent core 12, and is adhered with the absorbent core 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com