Cigar tobacco four-segment fermentation method

A technology for cigar tobacco leaves and fermentation method, which is applied in the fields of tobacco, tobacco preparation, and tobacco processing, can solve the problems of insufficient uniformity of tobacco leaf quality, rough control method, poor controllability of fermentation process, etc., and achieves stable quality and improves overall quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

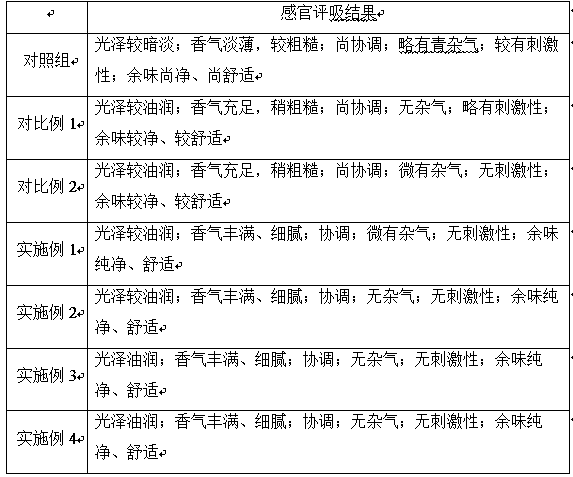

Examples

Embodiment 1

[0038] Embodiment 1 of the present invention provides a four-stage fermentation method for cigar tobacco leaves, comprising the following steps:

[0039] (1) Raw material pretreatment stage: cigar tobacco leaf raw materials in stock, after vacuum rehydration, the moisture content reaches 18%, and then remove sundries, mildewed tobacco leaves and seriously variegated tobacco leaves;

[0040] (2) Freezing and killing insects stage: the pretreated cigar leaves are put into the freezer at a rate of 100Kg / box. Store for 10 days;

[0041] (3) Primary stacking fermentation treatment stage: freeze the sterilized tobacco leaves, after the room temperature is balanced, soak the handle to increase the moisture content, and then start stacking fermentation. Tobacco stems are immersed in water with a depth of about 40mm, water temperature of 35°C, and soaking time of 2min. ℃, 44℃, 50℃, the fermentation period is 60 days, 85 days, 110 days respectively;

[0042](4) Secondary stacking fer...

Embodiment 2

[0045] Embodiment 2 of the present invention provides a four-stage fermentation method for cigar tobacco leaves, comprising the following steps:

[0046] (1) Raw material pretreatment stage: cigar tobacco leaf raw materials in stock, after vacuum rehydration, the moisture reaches 20%, and then remove sundries, mildewed tobacco leaves and seriously variegated tobacco leaves;

[0047] (2) Freezing and killing insects stage: the pretreated cigar leaves are put into the freezer at a rate of 100 Kg / box. Tobacco leaves are stored for 10 days;

[0048] (3) Primary stacking fermentation treatment stage: freeze the sterilized tobacco leaves, after the room temperature is balanced, soak the handle to increase the moisture content, and then start stacking fermentation. Tobacco stems were immersed in water with a depth of about 60mm, water temperature of 35°C, and soaking time of 1min. The moisture content of wrapper tobacco leaves, binder tobacco leaves, and filler tobacco leaves were c...

Embodiment 3

[0052] Embodiment 3 of the present invention provides a four-stage fermentation method for cigar tobacco leaves, comprising the following steps:

[0053] (1) Raw material pretreatment stage: cigar tobacco leaf raw materials in stock, after vacuum rehydration, the moisture reaches 20%, and then remove sundries, mildewed tobacco leaves and seriously variegated tobacco leaves;

[0054] (2) Freezing and killing insects stage: the pretreated cigar leaves are put into the freezer at a rate of 100 Kg / box. Tobacco leaves are stored for 10 days;

[0055] (3) Primary stacking fermentation treatment stage: freeze the sterilized tobacco leaves, after the room temperature is balanced, soak the handle to increase the moisture content, and then start stacking fermentation. Tobacco stems are immersed in water with a depth of about 50mm, water temperature of 35°C, and soaking time of 2min. ℃, 44℃, 50℃, the fermentation period is 60 days, 85 days, 110 days respectively;

[0056] (4) Secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com