Ploughing machine with residue treatment function

A residue and function technology, applied in the field of plow machines with residue treatment function, can solve the problems that the residue cannot be effectively cleaned, and the strength of the plow head can be increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

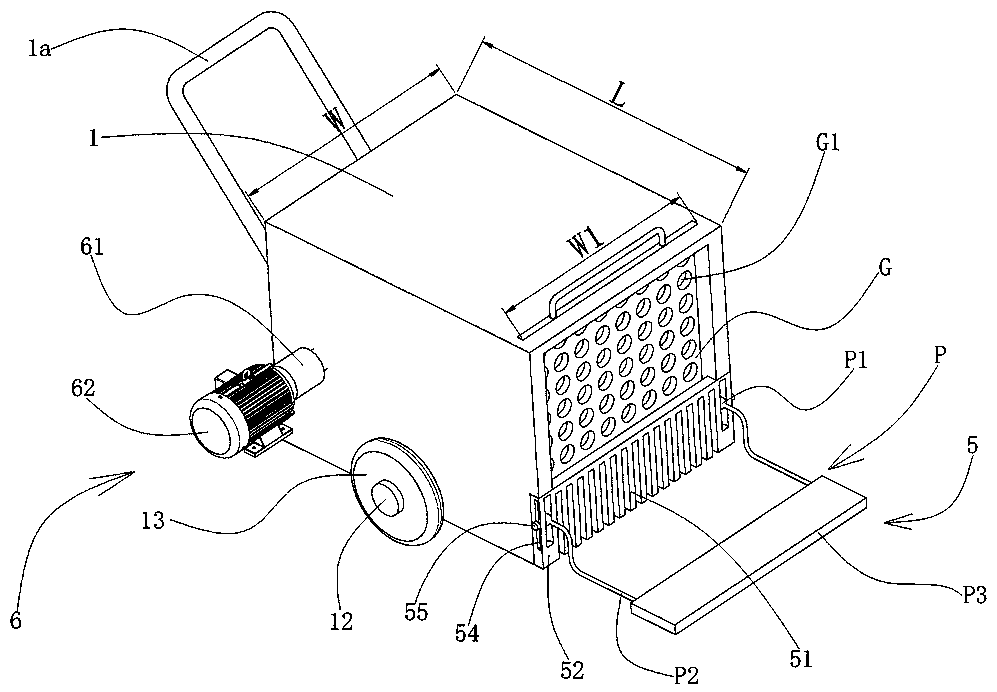

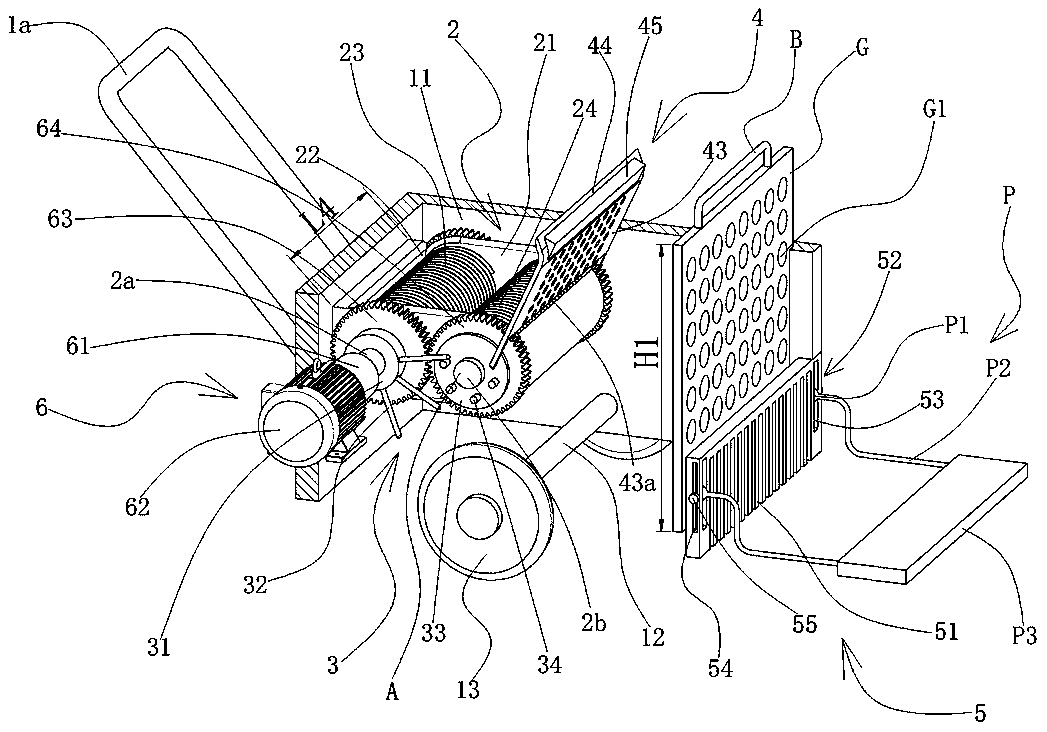

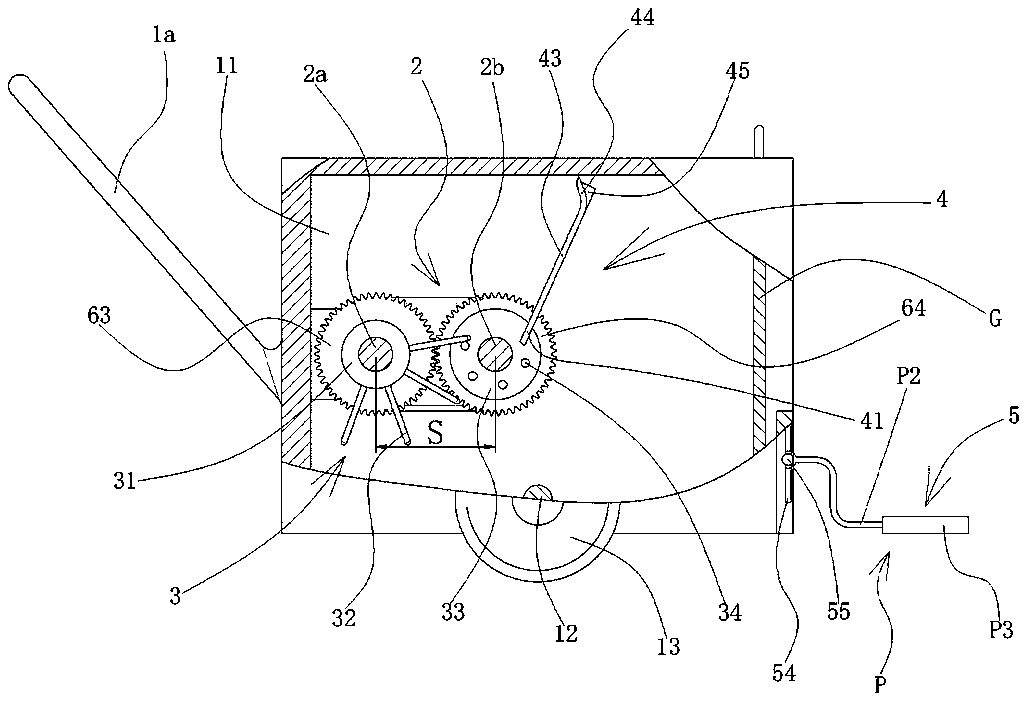

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, a kind of plowing machine with residue processing function, comprises frame 1 with push rod 1a, is characterized in that: frame 1 is provided with inner cavity 11, and frame 1 among the present invention can be set to rectangular , the push rod 1a is welded on the outer surface of one side of the frame 1, the inner cavity 11 is formed by shelling the rectangular frame 1, the width of the inner cavity 11 can be set to 90% to 95% of the width W of the frame 1, the inner cavity One side of 11 is provided with a residue cutting device 2, the residue cutting device 2 in this device is arranged on the inner wall surface of the side close to the push rod 1a in the inner cavity 11, the residue cutting device 2 includes a driving shaft 2a, and the two sides of the driving shaft 2a A symmetrically distributed intermittent device 3 is provided. The intermittent device 3 in the present invention is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com