Filling device

A filling device, the technology of the opposite surface, applied in the directions of packaging, transportation and packaging, the type of packaged items, etc., can solve the problems of damaged sealing and deteriorating contents, etc., to improve the degree of design freedom, reduce the manufacturing burden, and simplify the device. effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

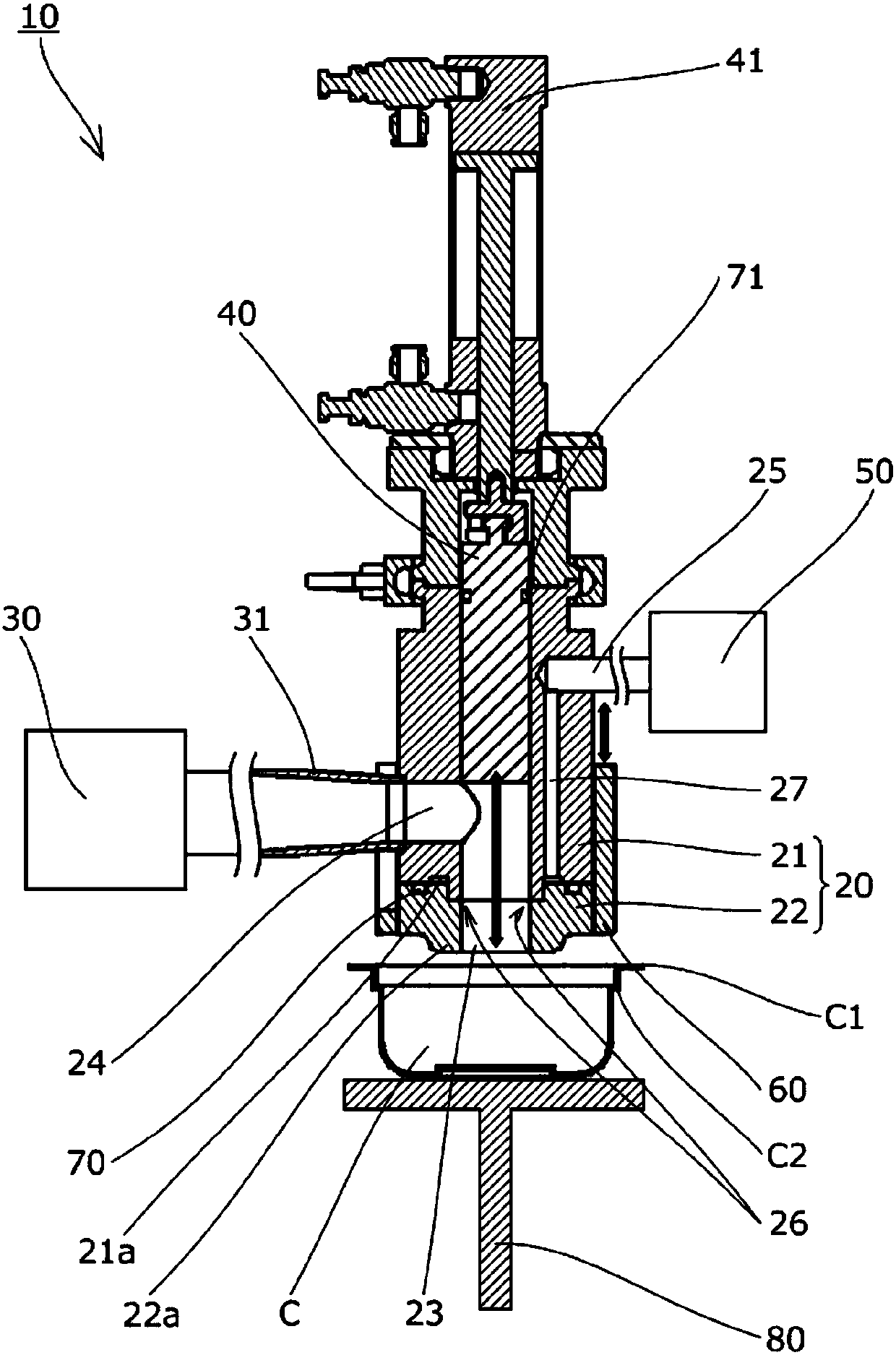

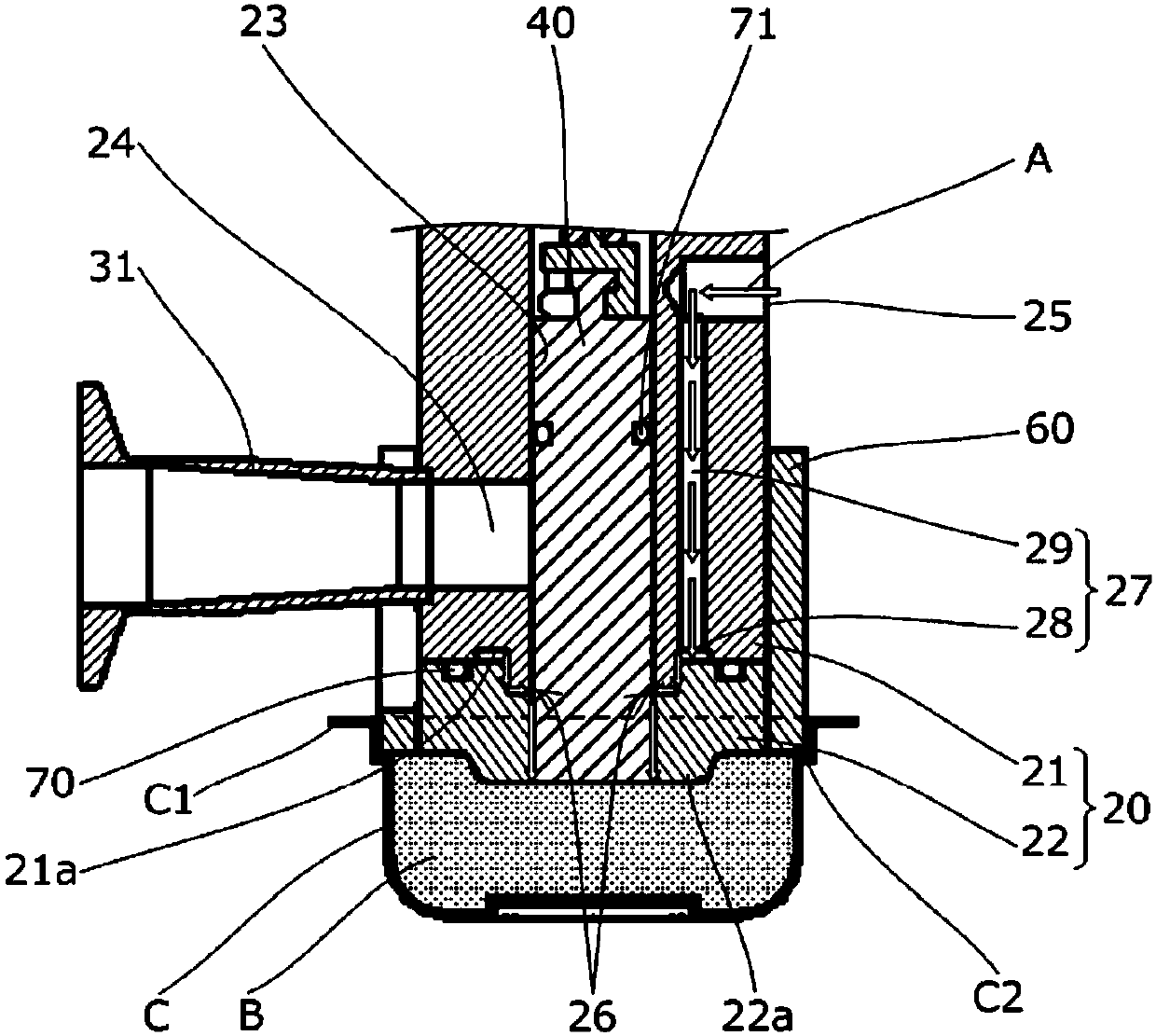

[0030] Hereinafter, the filling device 10 which concerns on one Embodiment of this invention is demonstrated based on drawing.

[0031] The filling device 10 fills the viscous contents B such as meat processed products into the container C, such as figure 1As shown, the filling device 10 includes: a filling nozzle 20 having a nozzle hole 23; a content supply unit 30 that supplies the content B to the nozzle hole 23; The content B supplied to the nozzle hole 23 is pushed out downward; the gas supply unit 50 supplies the gas A; the nozzle cover 60 is arranged on the outer periphery of the filling nozzle 20; the annular first liner The gasket 70 and the second gasket 71, which seal the respective parts; and the container lifter 80, which moves the container C up and down.

[0032] Below, based on Figure 1 ~ Figure 3 Each component of the filling device 10 will be described.

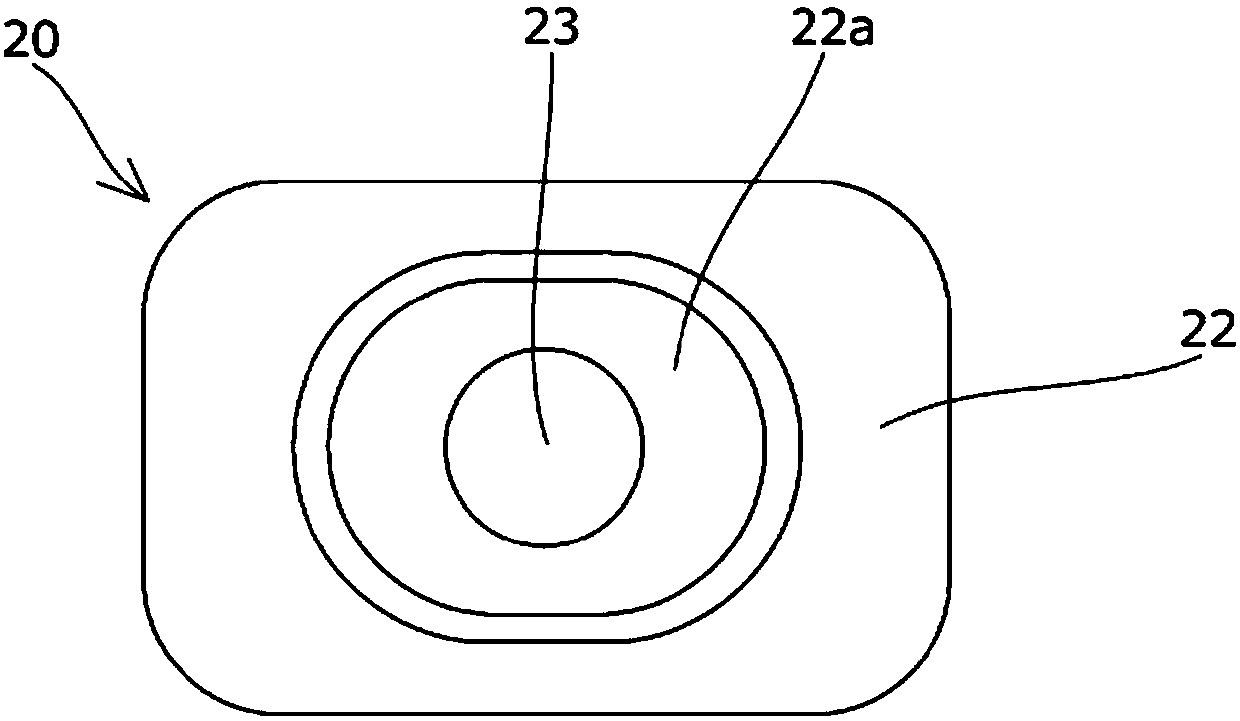

[0033] First, if figure 1 , figure 2 As shown, the filling nozzle 20 has: a cylindrical nozzle h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com