Pored fungus stick forming mechanism and fungus stick forming method

A technology of forming mechanism and fungus stick, which is applied in the fields of botanical equipment and methods, horticulture, plant cultivation, etc., can solve the problems of long growth cycle of edible fungus, inconsistent fungus age, low production efficiency of edible fungus, etc. Consistent, high production efficiency, good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

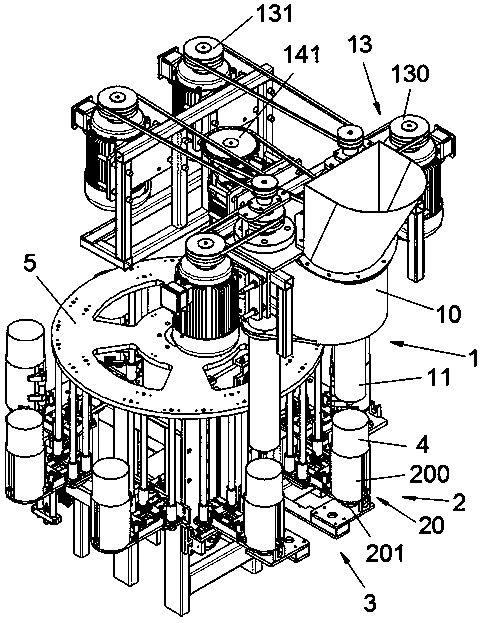

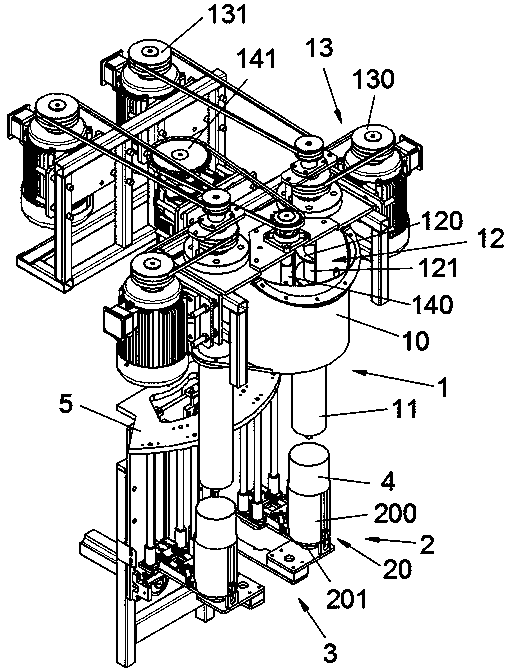

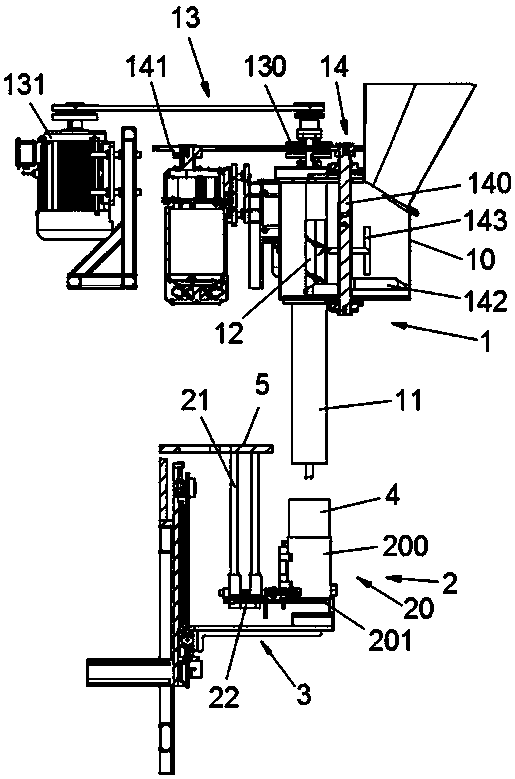

[0038] see Figure 1 to Figure 8 , a kind of bacteria stick forming mechanism with holes, comprising a feeding mechanism 1 and a charging mechanism 2; the feeding mechanism 1 includes a discharge cylinder 11, an extrusion screw 12 and the bacteria material delivered to the discharge cylinder 11; The extrusion screw 12 passes through the discharge barrel 11 from top to bottom and extends to the bottom of the discharge barrel 11; the screw blade 120 for feeding is fixed on the extrusion screw 12 in the discharge barrel 11; the charging Mechanism 2 includes a charging platform 20 arranged below the discharge barrel 11, and the charging platform 20 moves up and down through a lifting mechanism 3; bacteria bags 4 are placed on the charging platform 20, and the extrusion screw 12 rotates to discharge The bacterium material in the barrel 11 is tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com