X-ray detector based on perovskite material and preparation method thereof

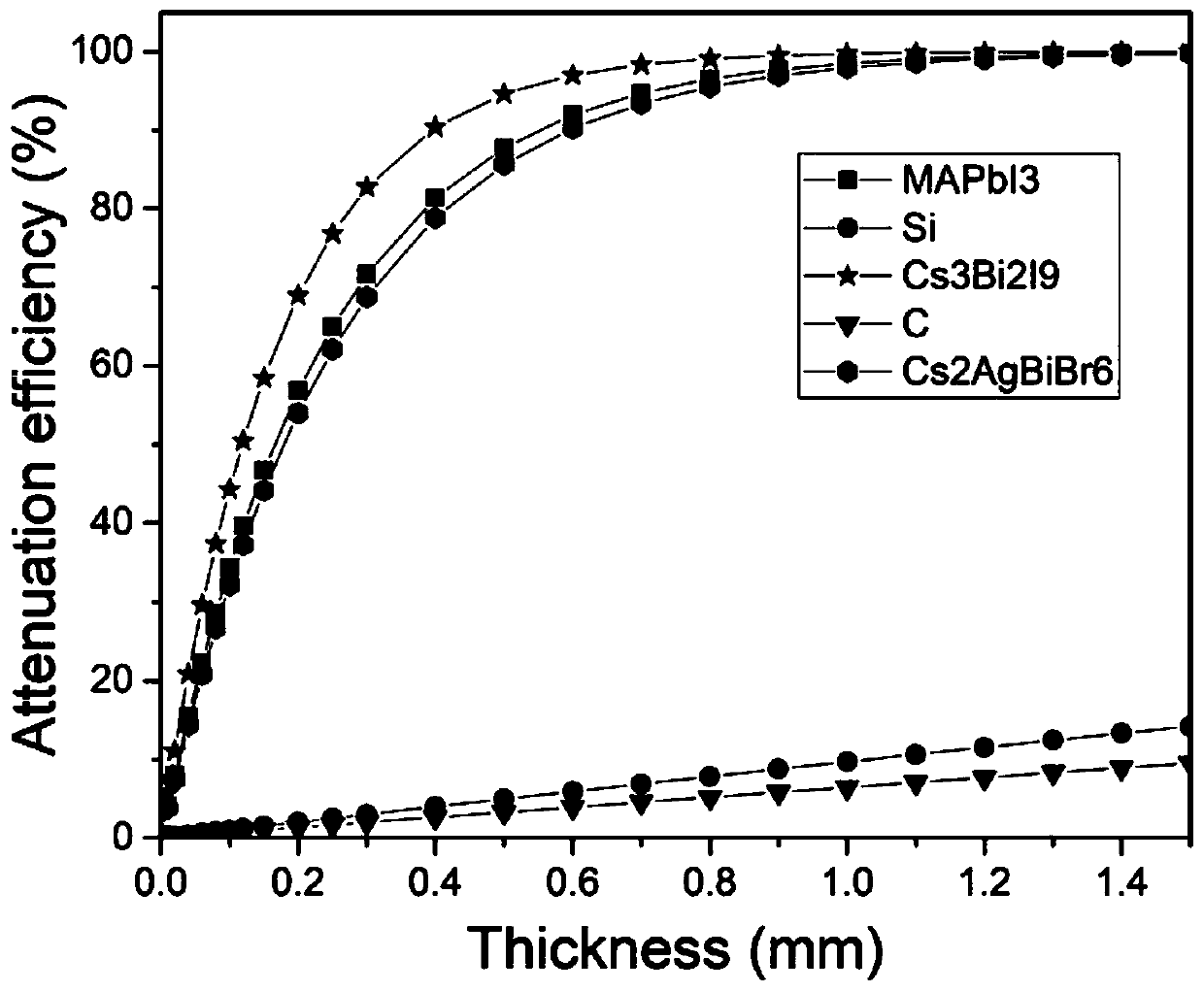

A perovskite material and X-ray technology, applied in the field of perovskite-based X-ray detectors and its preparation, can solve the problems of small atomic number of materials, insufficient detection dose, complex preparation process, etc., and achieve atomic number Large size, simple structure, and short preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the X-ray detector based on the perovskite material of the present invention, specifically, comprises the following steps:

[0030] Step 1, weigh AI and BI according to the molar ratio of 3:2 3 The raw material is dissolved in an organic solvent to obtain a mixed precursor liquid with a concentration of 0.2-1.5 mol / L; among them, AI is CsI, CH 3 NH 3 I, RbI; BI 3 for BiI 3 , SbI 3 ; The organic solvent is at least one of γ-butyrolactone, N, N-dimethylformamide, dimethyl sulfoxide and N-methyl-2-pyrrolidone;

[0031] Step 2, put the mixed precursor liquid into a crystallization dish, seal it, heat it to 60-100°C, and keep it for 2-48 hours to make it reach a sufficient dissolution equilibrium, then take the supernatant to obtain a fully saturated solution of the precursor;

[0032] Step 3, place the fully saturated solution of the precursor at an ambient temperature 2-5°C lower than the heating termination temperature in step 2, and gradual...

Embodiment 1

[0040] Step 1, weigh 9.36gCsI and 14.16gBiI according to the molar ratio of 3:2 3 The raw materials were dissolved in 30 mL of N,N-dimethylformamide solvent to obtain a mixed precursor liquid with a concentration of 0.4 mol / L.

[0041] Step 2, put the mixed precursor liquid into a crystallization dish, seal it, heat it to 70°C, and keep it for 12 hours to make it reach a sufficient dissolution equilibrium, then take the supernatant to obtain a fully saturated solution of the precursor;

[0042] Step 3, put the fully saturated solution of the precursor in an oven at 65°C, and gradually raise the temperature at a rate of 2°C / day until the crystals are precipitated, and then continue to increase the temperature by 8°C at a rate of 2°C / day to obtain a larger size Cs 3 Bi 2 I 9 Perovskite single crystal;

[0043] Step 4, taking out the crystal and drying it;

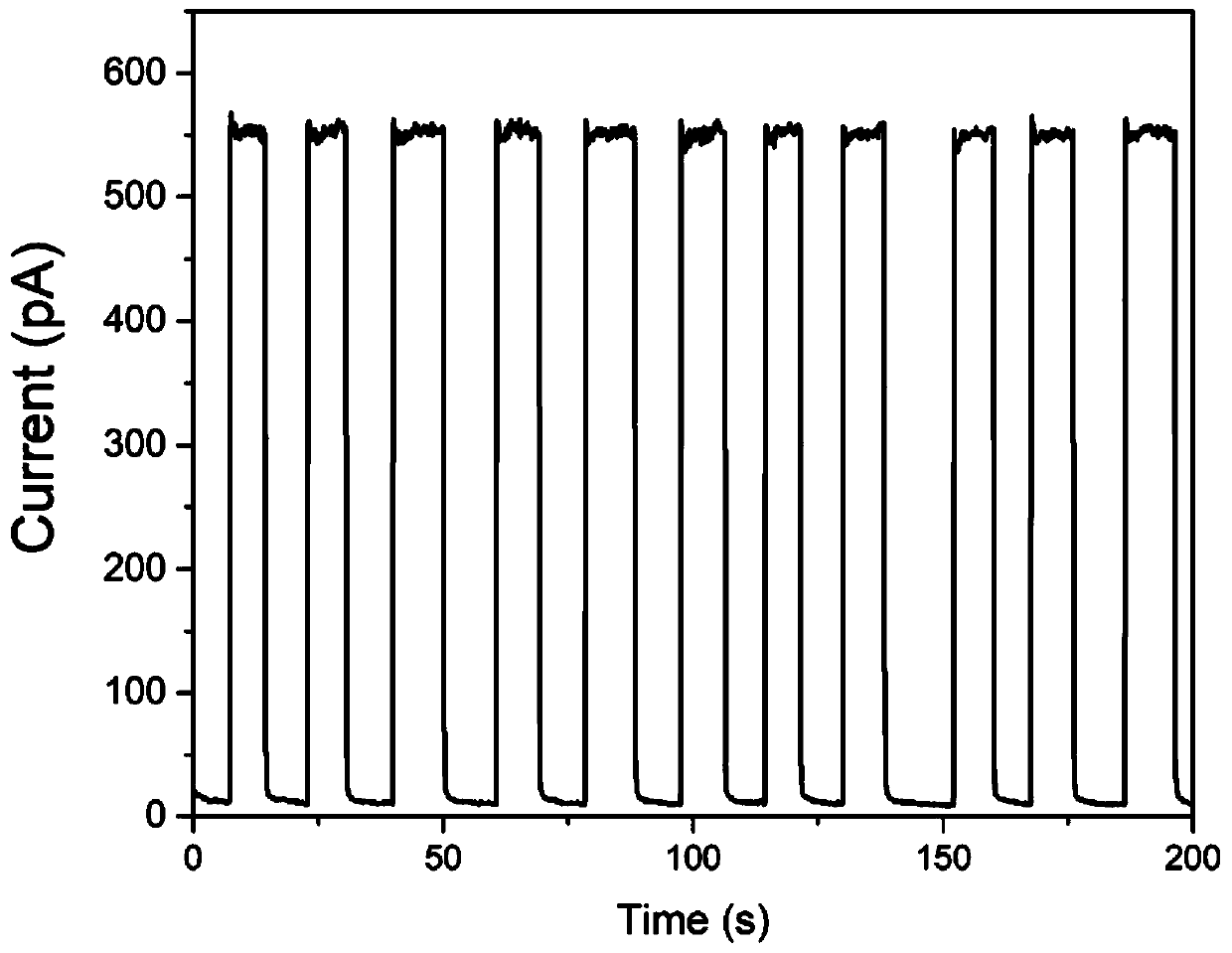

[0044] Step 5, evaporating Au electrodes on the surface of the crystal.

Embodiment 2

[0046] Step 1, weigh 5.72g CH according to the molar ratio 3:2 3 NH 3 I and 14.16g BiI 3 The raw materials were dissolved in 30 mL of γ-butyrolactone solvent to obtain a mixed precursor liquid with a concentration of 0.4 mol / L.

[0047] Step 2, put the mixed precursor liquid into a crystallization dish, seal it, heat it to 80°C, and keep it for 24 hours to make it reach a sufficient dissolution equilibrium, then take the supernatant to obtain a fully saturated solution of the precursor;

[0048] Step 3, put the fully saturated solution of the precursor in an oven at 75°C, and gradually raise the temperature at a rate of 2°C / day until the crystals are precipitated, and then continue to increase the temperature by 8°C at a rate of 2°C / day to obtain a larger size CH 3 NH 3 Bi 2 I 9 Perovskite single crystal;

[0049] Step 4, taking out the crystal and drying it;

[0050] Step 5, evaporating Au electrodes on the surface of the crystal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com