Concrete pipe and manufacturing process thereof

A concrete pipe and manufacturing process technology, which is applied in the direction of manufacturing tools, pipes, rigid pipes, etc., can solve problems such as cracks at the socket, failure to meet the use requirements, and quality problems of concrete pipes, so as to improve waterproof performance, increase the success rate of preparation, Effect of improving strength and water-blocking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

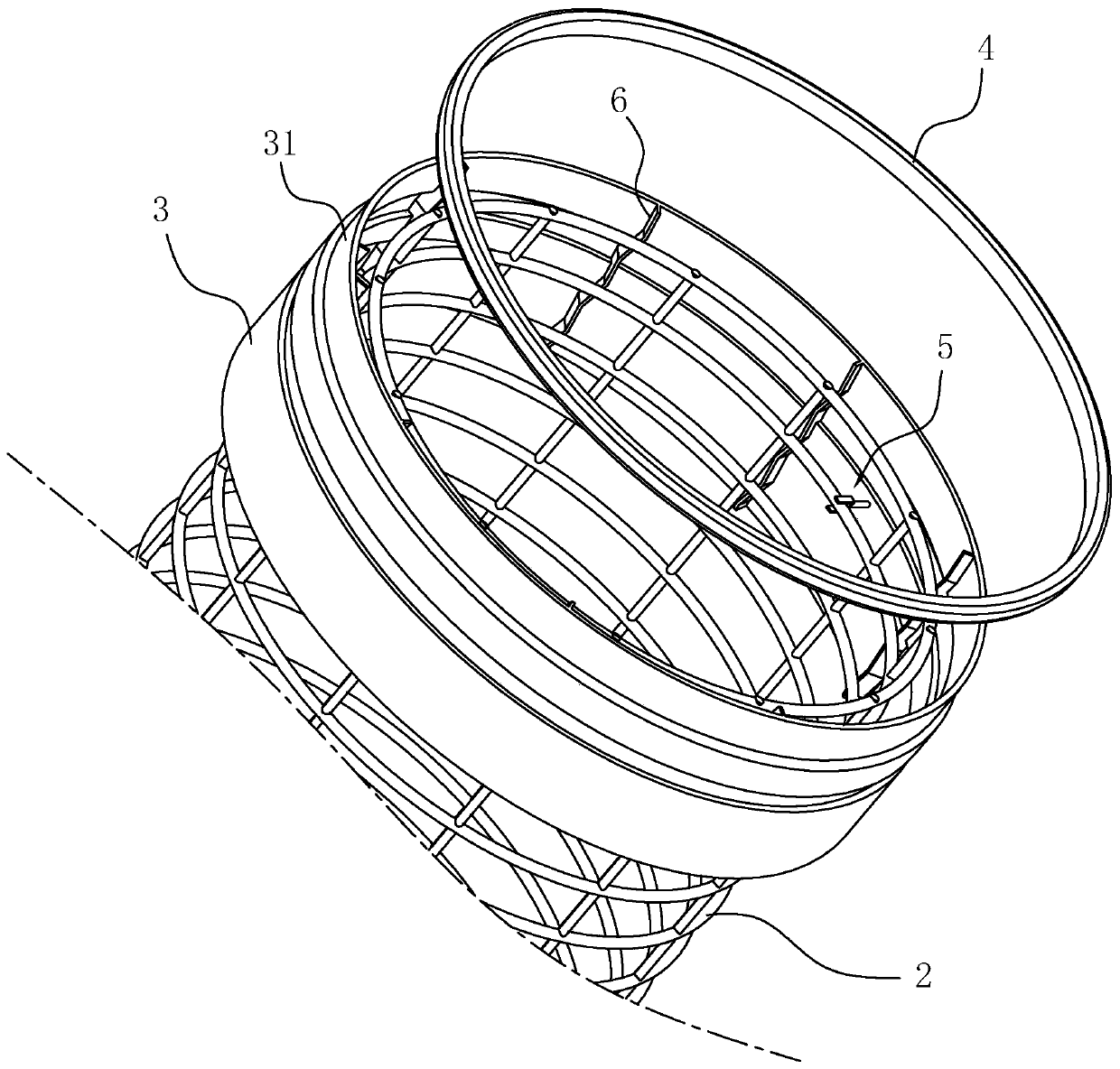

[0045] A concrete pipe, as shown in the figure, includes a pipe body 1 with a socket end 11 and a socket end 12 arranged on the pipe body 1 .

[0046] As shown in the figure, the diameter of the outer wall of the socket end 11 of the pipe body 1 is greater than the diameter of the outer wall of the socket end 12 of the pipe body 1; The plug-in connection between two adjacent pipe bodies 1 is fixed. The pipe body 1 is formed by pouring concrete, and is named as the concrete layer 13; the concrete layer 13 is provided with steel keels 2, thereby increasing the overall strength of the pipe body 1.

[0047]As shown in the figure, since the pipe body 1 is formed by pouring concrete, air bubbles are likely to be generated in the concrete layer 13 during the pouring process; 12 The pipe wall is relatively thin, making the concrete layer 13 prone to cracks, thereby affecting the waterproof performance of the pipe body 1 . Therefore, a water blocking pipe 3 made of PMMA is provided a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com