Sand-out returning fluid stop valve for oil well and application method of stop valve

A shut-off valve and sand washing technology, which is applied in the direction of earthwork drilling, wellbore flushing, wellbore/well components, etc. It can solve the problem that the check valve cannot be installed in the well string, and the installation of the check valve cannot meet the construction requirements and cannot be achieved. environmental protection law and other issues to achieve the effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

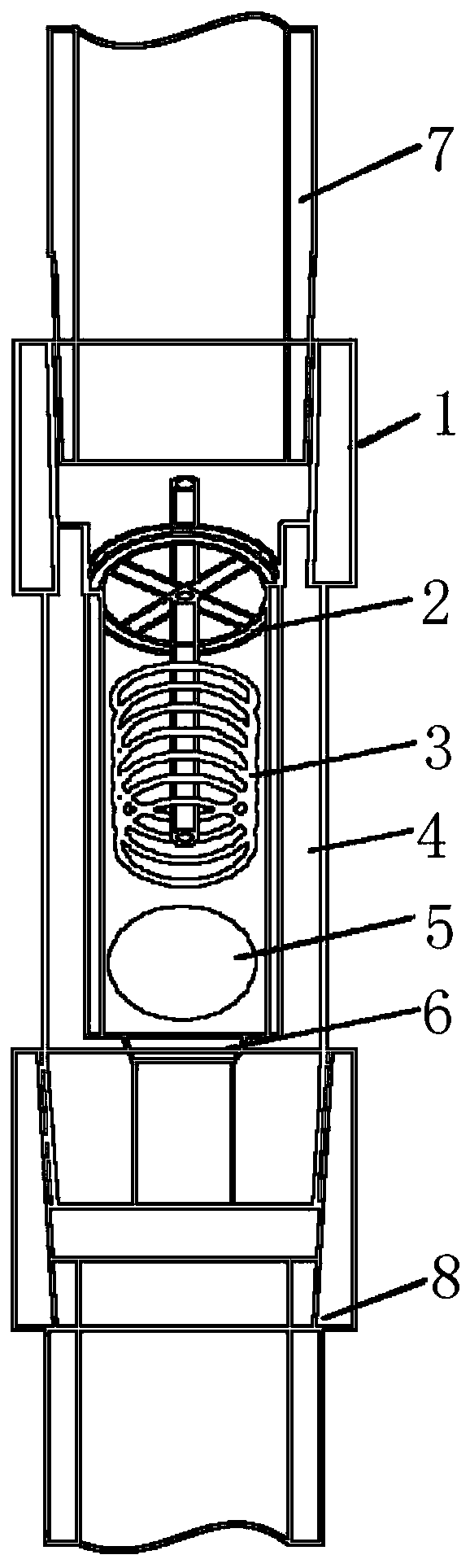

[0022] A cut-off valve for oil well sand flushing and return fluid, comprising an upper joint 1, a baffle plate 2, a pressure balance spring 3, a stop valve body 4, a setting ball 5, a ball seat 6, an upper oil pipe pin 7 and a lower oil pipe box 8 , the upper oil pipe pin 7, the upper joint 1, the stop valve body 4 and the lower oil pipe box 8 are connected sequentially from top to bottom, and the inside of the stop valve body 4 is provided with a baffle plate 2, a pressure balance spring 3, The setting ball 5 and the ball seat 6 are connected to the pressure balance spring 3 under the baffle plate 2 and both the baffle plate 2 and the pressure balance spring 3 are located on the upper part of the stop valve body 4, and the ball seat 6 is connected to the lower part of the stop valve body 4 for setting. The ball 5 can be set on the ball seat 6 .

Embodiment 2

[0024] Such as figure 1 As shown, a cut-off valve for oil well sand flushing return fluid includes an upper joint 1, a baffle plate 2, a pressure balance spring 3, a stop valve body 4, a setting ball 5, a ball seat 6, an upper oil pipe pin 7 and a lower oil pipe The female buckle 8, the upper oil pipe male buckle 7, the upper joint 1, the shut-off valve body 4 and the lower oil pipe buckle 8 are connected sequentially from top to bottom, and the inside of the shut-off valve body 4 is provided with a baffle 2 and a pressure balance from top to bottom. Spring 3, setting ball 5 and ball seat 6, the baffle plate 2 is connected to the pressure balance spring 3 and the baffle plate 2 and pressure balance spring 3 are located on the upper part of the stop valve body 4, and the ball seat 6 is connected to the lower part of the stop valve body 4 , The setting ball 5 can be set on the ball seat 6. This oil well sand flushing return fluid cut-off valve is designed by using the principle...

Embodiment 3

[0034] On the basis of embodiment 2, the use method of the oil well sand flushing return liquid shut-off valve is as follows:

[0035]During the process of pumping in liquid for circulating sand flushing, the liquid flow pushes the setting ball 5 away from the ball seat 6, and the shut-off valve of the oil well sand flushing return liquid is in an open state, and the sand flushing operation can be carried out;

[0036] When changing a single piece, stop pumping liquid, the setting ball 5 falls on the ball seat 6 under the action of its own weight and the elastic force of the pressure balance spring 3, the shut-off valve of the oil well sand flushing return fluid is closed, and the wellhead stops returning water ;

[0037] When it is necessary to establish a positive circulation channel, the setting ball 5 can be crushed by lame pressure, and the shut-off valve of the oil well sand flushing and return fluid can be opened to carry out positive and negative circulation.

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com