Assembled ecological slope protection and construction method thereof

An ecological slope protection and prefabricated technology, applied in the direction of coastline protection, etc., can solve the problems such as the porosity of slope protection blocks cannot be changed, poor anti-overturning ability, poor stability, etc., achieve good ecological protection effect, improve shear resistance, and good ecological effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

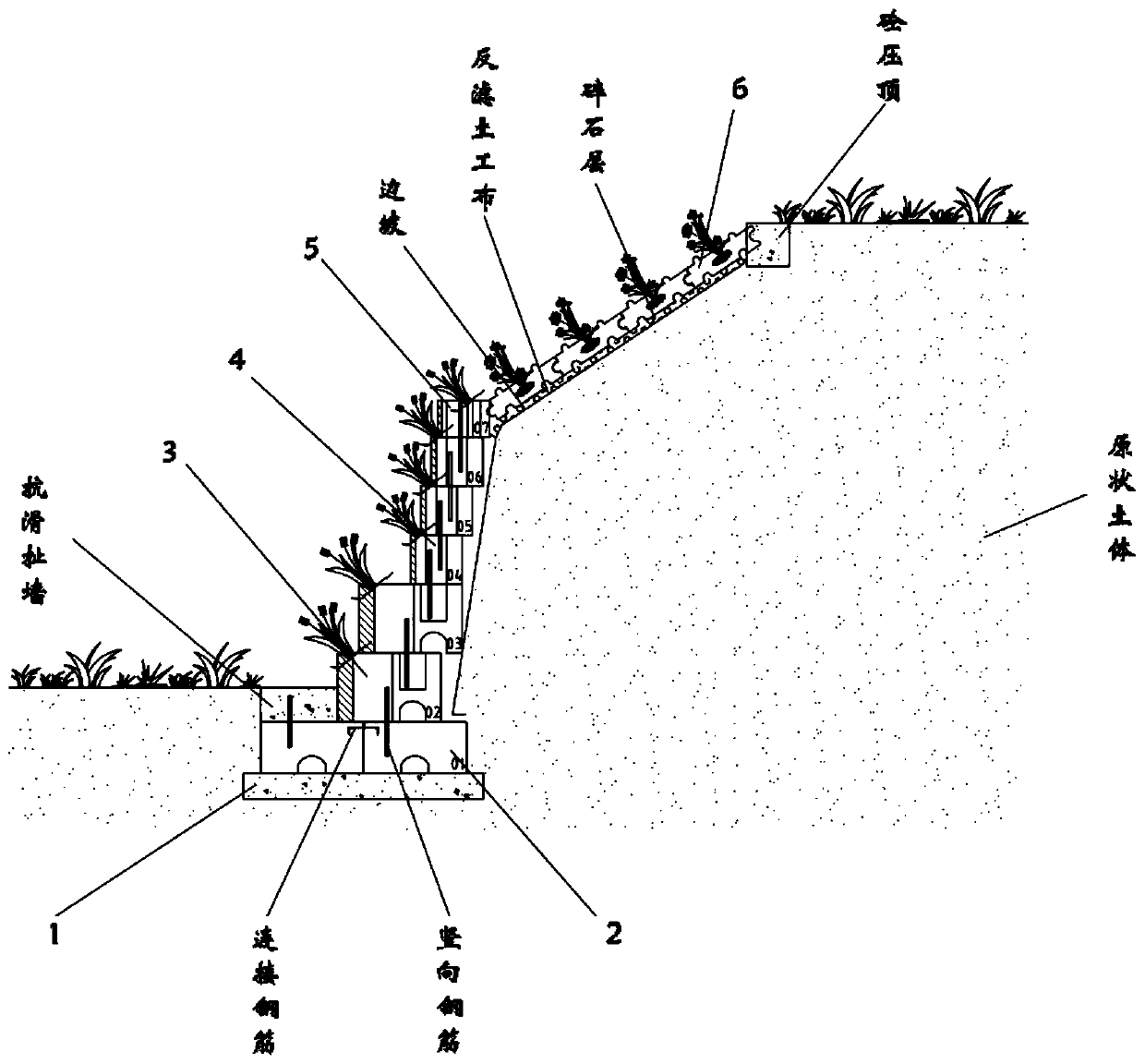

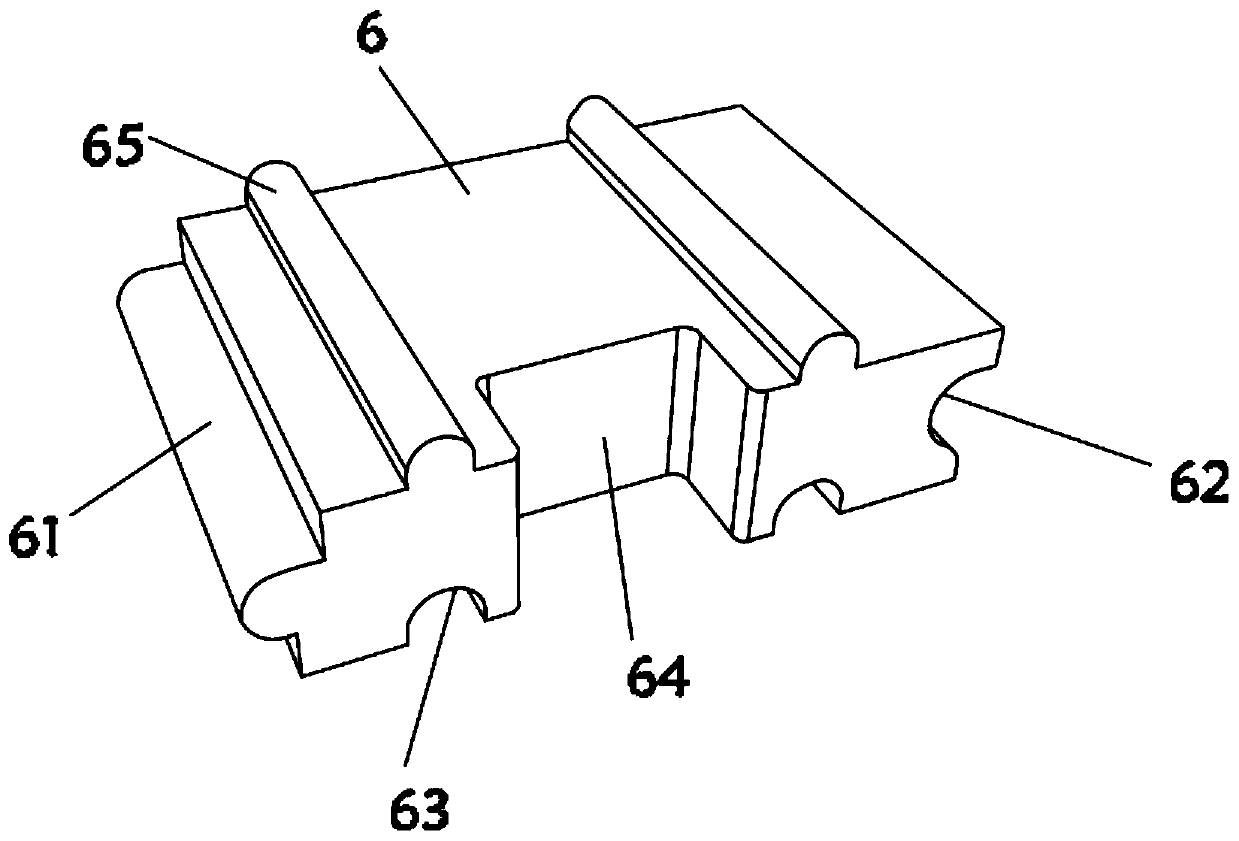

[0042] On the one hand, the present invention provides a kind of prefabricated ecological slope protection, such as figure 2 As shown, it includes foundation blocks 2, large blocks 3, medium blocks, small blocks 4, roof blocks 5 and slope protection blocks 6, and the top of the base blocks 2 is laid with multiple large blocks 3, and the large blocks The top of the block 3 is paved with a plurality of small blocks 4, the top of the small blocks 4 is paved with a plurality of topping blocks 5, and one end of the topping block 5 is paved with a plurality of slope protection blocks 6, and the two ends of the slope protection blocks 6 are Guide rail projections 61 and limit slide grooves 62 are respectively provided, a plurality of drainage grooves 63 are provided at the bottom of the slope protection block, and a plurality of anti-slip protrusions 65 are installed at the top of the slope protection block 6 .

[0043] In the present embodiment, the size of the guide rail projectio...

Embodiment 2

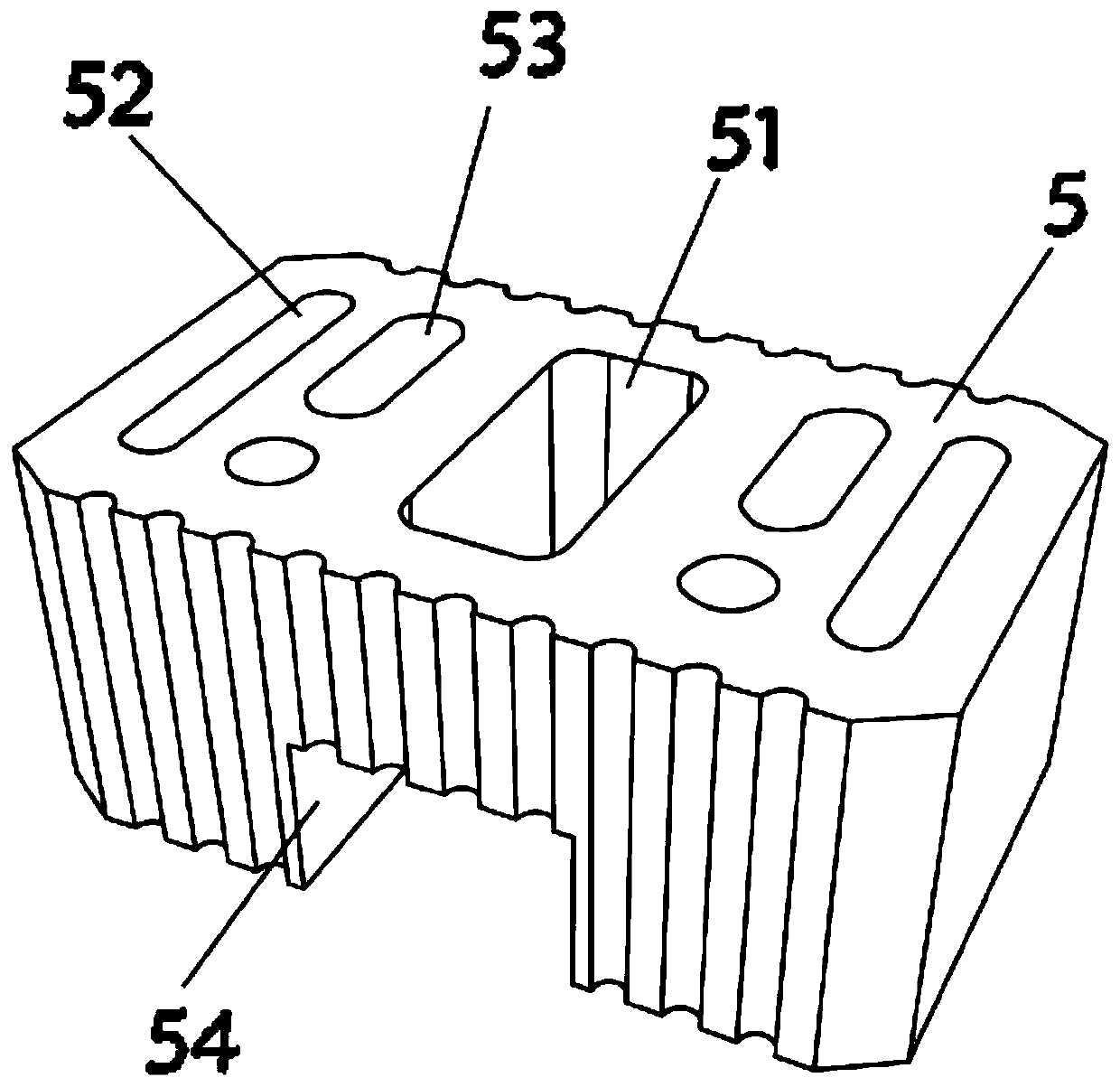

[0050] As the second embodiment of the present invention, in order to facilitate the assembly of the top block 5, the present invention also improves the top block 5, as a preferred embodiment, such as image 3 As shown, the top center of the top block 5 is provided with a first ecological hole 51, and the top sides of the top block 5 are respectively provided with a second ecological hole 52, and the inside of the top block 5 is also provided with an anchor hole for the top block. 53. The bottom of the top block 5 is provided with a fork transport groove 54 for the top block.

[0051] In this embodiment, the topping block 5 is formed by pouring concrete, the overall structure is hard, and the stabilizing effect is good.

[0052] Specifically, the anchoring hole 53 of the topping block runs through the topping block 5. During construction, a plurality of topping blocks 5 are stacked and placed, and the anchoring holes 53 of the topping block 5 at the upper and lower ends are a...

Embodiment 3

[0058] As a third embodiment of the present invention, in order to facilitate the assembly of the basic block 2, the present invention also makes improvements to the basic block 2, as a preferred embodiment, such as Figure 4 with Figure 5 As shown, one end of the basic block 2 is provided with a pair of occlusal strips 21, the other end of the basic block 2 is provided with a pair of occlusal grooves 22, and one side of the basic block 2 is provided with a plurality of longitudinal connecting grooves 23, the basic block 2 The top of the base is provided with a forklift groove 24, and the inside of the base block 2 is provided with a plurality of base block anchor holes 25.

[0059] In this embodiment, the basic block 2 is in the shape of "I", which can save materials and is convenient for stacking and transportation. At the same time, the overall strength of the basic block 2 is high, forming a stable barrier with the wall.

[0060] Further, the snapping strip 21 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com