Carbon-coated silver microspheres and preparation method thereof, black pigment printing paste and application thereof

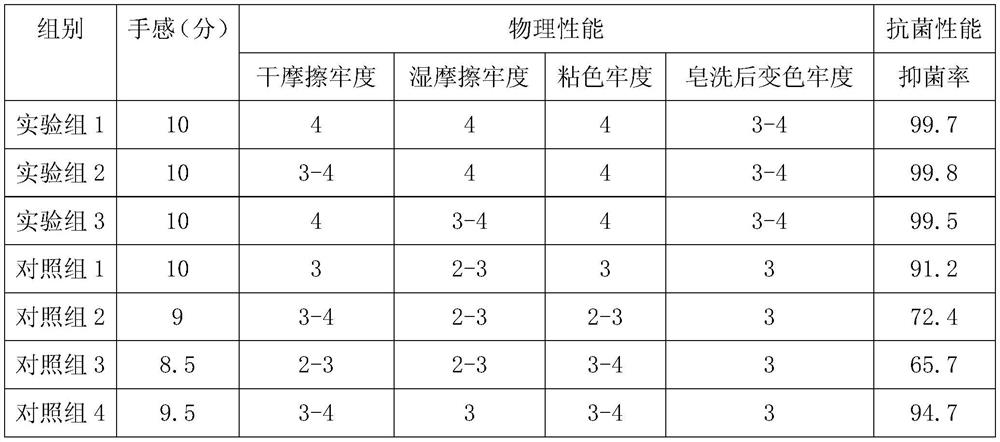

A printing color paste and black paint technology, applied in the field of fabric printing and dyeing, can solve the problems of easy aggregation of antibacterial agents, no antibacterial agents, poor quality, etc., achieve strong tinting power and hiding power, improve antibacterial performance, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A carbon-coated silver microsphere with a core-shell structure, the particle size of the carbon-coated silver microsphere is 50nm, wherein the particle size of the silver particle is 10nm, and the thickness of the carbon shell layer is 20nm.

[0031] The above-mentioned preparation method of carbon-coated silver microspheres with a core-shell structure comprises the following steps:

[0032](1) Preparation of silver particles: Mix and stir 0.01g of trisodium citrate and 1mL of deionized water until completely dissolved to obtain a trisodium citrate solution; add 0.01g of silver nitrate to the trisodium citrate solution and 50mL of deionized water, heated at 100°C for 20min, then added 1mL of an aqueous solution with a trisodium citrate content of 1%, stirred for 20min, stopped heating, continued stirring for 1, and then centrifuged at 800r / min; washed the centrifuged product with water Afterwards, disperse in 1 mL of absolute ethanol to obtain a silver particle mixture;...

Embodiment 2

[0040] A carbon-coated silver microsphere with a core-shell structure, the particle diameter of the carbon-coated silver microsphere is 90nm, wherein the particle diameter of the silver particle is 25nm, and the thickness of the carbon shell layer is 50nm.

[0041] The above-mentioned preparation method of carbon-coated silver microspheres with a core-shell structure comprises the following steps:

[0042] (1) Preparation of silver particles: Mix and stir 0.5 g of trisodium citrate and 60 mL of deionized water until completely dissolved to obtain a trisodium citrate solution; add 1.2 g of silver nitrate to the trisodium citrate solution and 450mL of deionized water, heated at 100°C for 25min, then added 15mL of an aqueous solution with a trisodium citrate content of 1%, stirred for 25min, stopped heating, continued to stir for 1.2 minutes, and then centrifuged at 900r / min; washed the centrifuged product with water Afterwards, disperse in 13mL of absolute ethanol to obtain a si...

Embodiment 3

[0050] A carbon-coated silver microsphere with a core-shell structure, the particle size of the carbon-coated silver microsphere is 200nm, wherein the particle size of the silver particle is 40nm, and the thickness of the carbon shell layer is 90nm.

[0051] The above-mentioned preparation method of carbon-coated silver microspheres with a core-shell structure comprises the following steps:

[0052] (1) Preparation of silver particles: 1g of trisodium citrate and 100mL of deionized water are mixed and stirred until completely dissolved to obtain a trisodium citrate solution; 2g of silver nitrate and 800mL of silver nitrate are added to the trisodium citrate solution Deionized water, heated at 100°C for 30min, then added 20mL of an aqueous solution with a trisodium citrate content of 1%, stirred for 30min, stopped heating, continued to stir for 1.5 minutes, and then centrifuged at 1000r / min; the centrifuged product was washed with water and dispersed In 20mL of absolute ethanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com