Smelting reduction furnace gas recycling device and method

A reduction furnace and coal gas technology, applied in waste gas treatment, climate sustainability, metal processing, etc., can solve the problems of furnace top gas recovery and utilization, high temperature, high calorific value, etc., and achieve low energy consumption, long service life, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

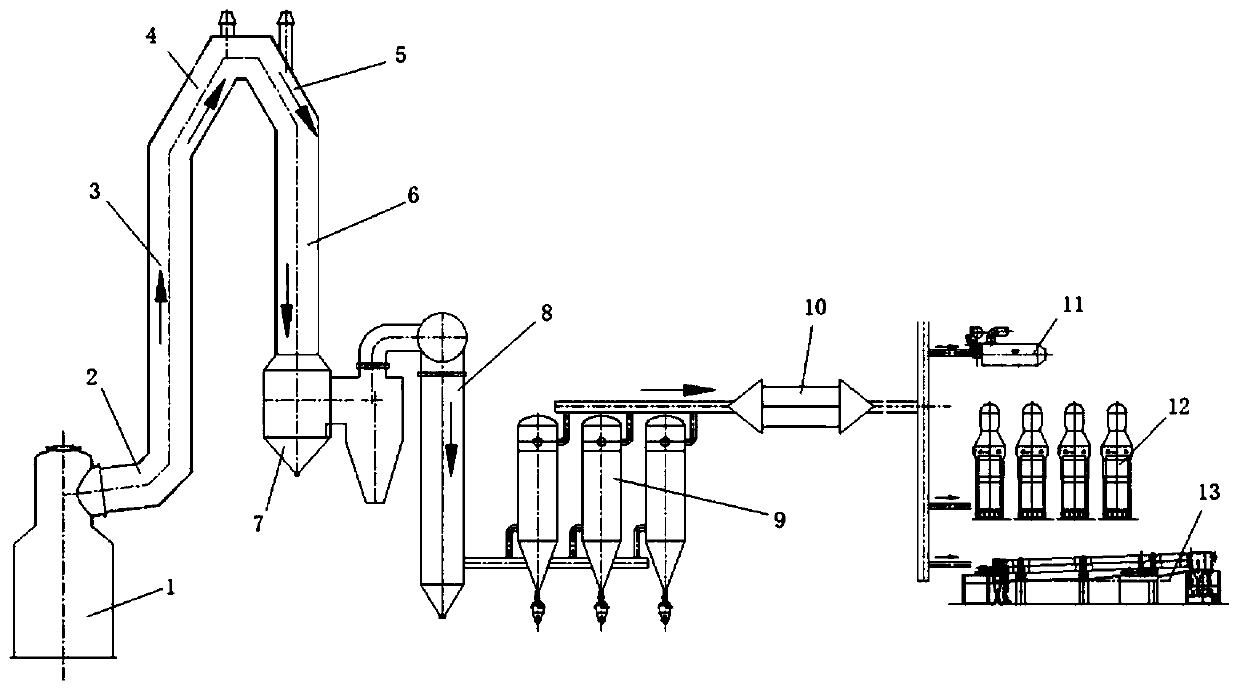

[0026] A smelting reduction furnace gas recycling system. The smelting reduction furnace gas recycling system includes: sequentially connected vaporization flue, cyclone dust collector, waste heat boiler, bag filter, and pressure regulating valve group. The outlets of the pressure regulating valve group are respectively It is connected with a coal powder preparation device, a hot blast stove, and a drying kiln, and the inlet of the vaporization flue is connected with a smelting reduction furnace.

[0027] The vaporization flue is divided into five parts, the furnace mouth section, the first section of the flue, the second section of the flue, the third section of the flue, and the fourth section of the flue. A hot water circulation pump is installed, which can realize forced cooling, and the last part is natural circulation, but it can also realize forced circulation vaporization cooling.

[0028] The cyclone dust collector adopts an upper cylinder and a lower cone structure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com