A kind of anti-reflection coating and its preparation method and application

A technology of anti-reflection and anti-reflection glass, applied in the field of coatings, can solve the problems of increased manufacturing cost, limited life, easy failure, etc., and achieve the effects of high weather resistance, high cost performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

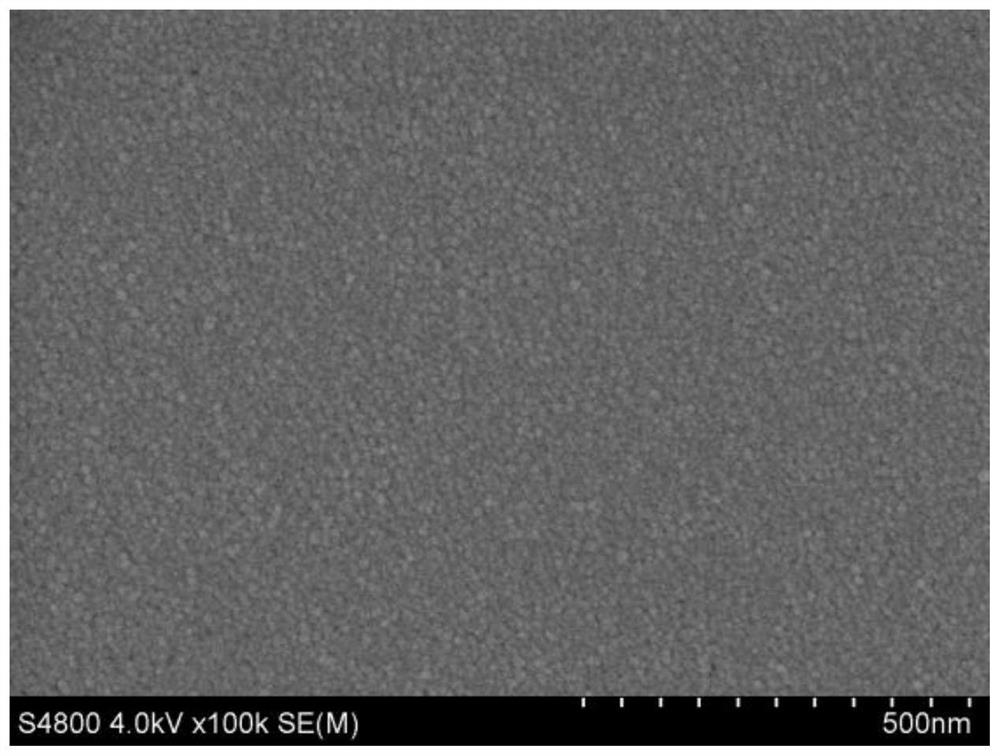

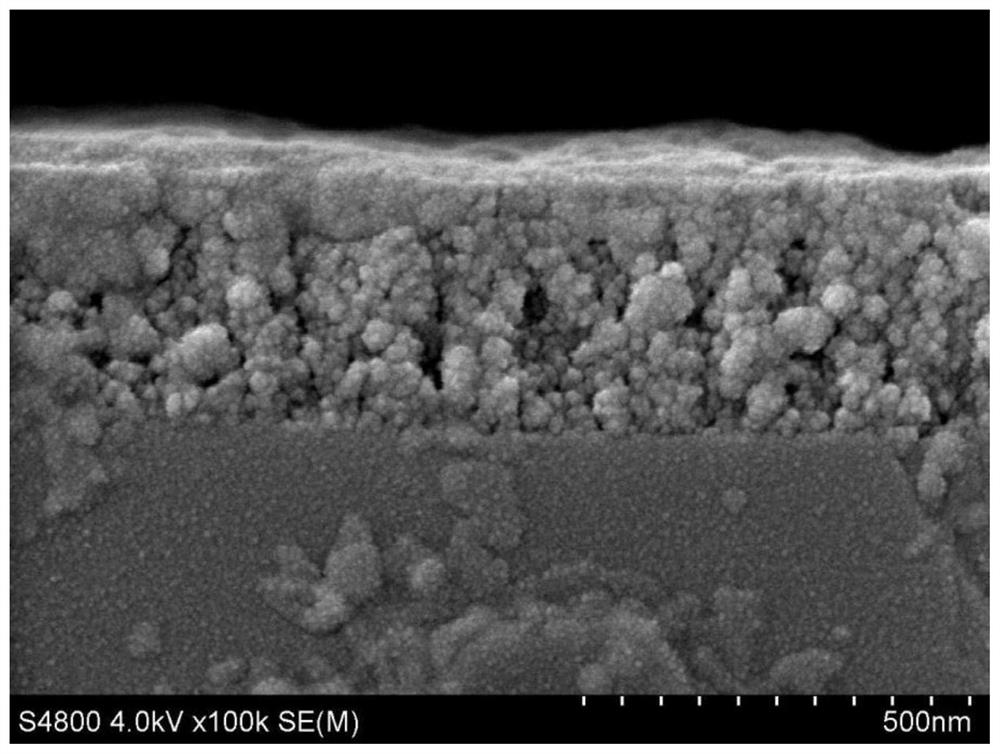

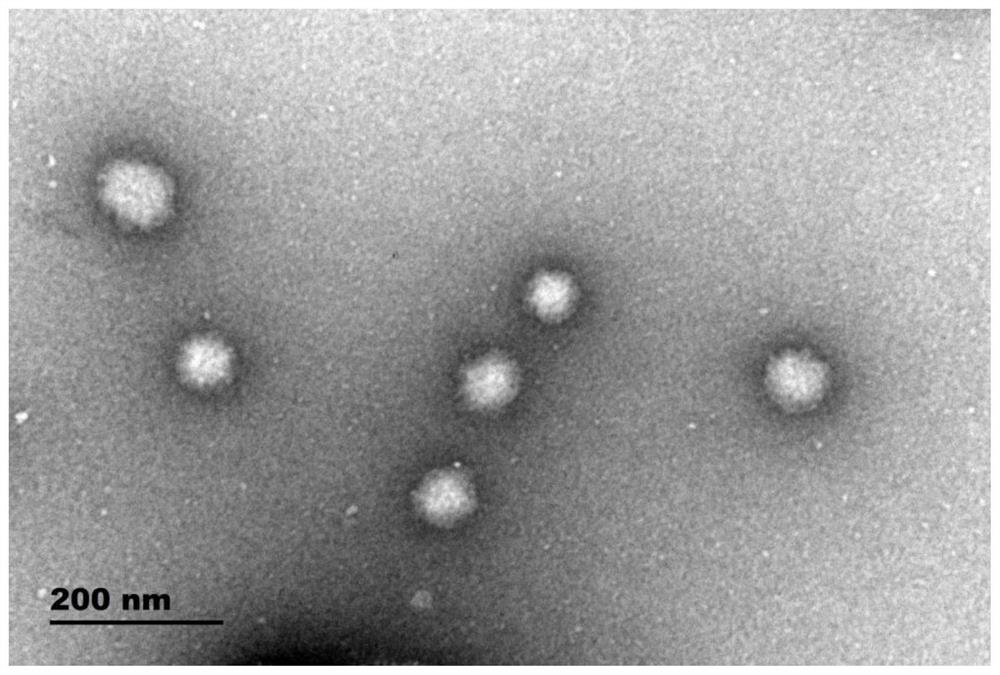

[0045] This embodiment provides a weather-resistant closed-cell antireflection coating, which is mainly composed of a silicon source, a hyperbranched resin, an additive, a catalyst, and a solvent. The silicon source is an alkoxysilane, the catalyst is an acid, and the solvent is an alcohol. The proportioning relationship of each component is calculated in parts by weight: 3%-5% of silicon source, 1-10% of hyperbranched resin, and 85%-96% of auxiliary agent, catalyst and solvent. The anti-reflection coating is made by one of the following methods:

[0046] (1) Dissolve the hyperbranched resin in a solvent, add a silicon source and a catalyst to the solvent in which the hyperbranched resin is dissolved, and fully react for 0.5-20 hours to obtain a sol containing composite nanoparticles with a core-shell structure, and then add additives , to obtain the anti-reflection coating; or

[0047] (2) Mix the silicon source, catalyst and solvent for 0.5-24 hours to prepare silica colloi...

Embodiment 2

[0052] This embodiment provides a specific preparation method of a weather-resistant closed-cell anti-reflection coating. The preparation method includes the following steps:

[0053] Step 1: At room temperature, add the diluted 0.1M catalyst hydrochloric acid into the solvent ethanol for stirring, add tetraethoxysilane (TEOS) during the stirring process, and stir for 24 hours to obtain a network silica colloid;

[0054] Step 2: Take six parts of the same amount of colloidal silica prepared in step 1, and add 1%, 2% and 3% of the colloidal silica by weight in the process of stirring the six parts of colloidal silica , 4%, 5%, 10% acrylate oligomers, stirred and reacted for 12h, to obtain weather-resistant type closed-cell anti-reflection coating of the present invention;

[0055] Step 3: Add 0.1% of the leveling agent by weight of silica colloid to the six parts of weather-resistant closed-cell anti-reflection coatings prepared in step 2 to obtain six parts of weather-resistan...

Embodiment 3

[0057] This embodiment provides another specific preparation method for weather-resistant closed-cell anti-reflection coatings. This preparation method includes the following steps:

[0058] Step 1: At room temperature, add 2%, 2.5%, 3%, 3.5%, 4%, 6% hyperbranched resin acrylate oligomers into ethanol solvent and fully dissolve;

[0059] Step 2: Add tetraethoxysilane (TEOS) and 0.1M hydrochloric acid catalyst to the fully dissolved hyperbranched resin ethanol solution obtained in step 1, and react for 24 hours to obtain the weather-resistant closed-cell anti-reflection coating of the present invention;

[0060] Step 3: Add 0.1% leveling aid by weight of silica colloid to the weather-resistant closed-cell anti-reflection coating in step 2. The leveling aid is one of acrylic, silicone, and fluorine-containing additives or more, to obtain a weather-resistant closed-cell anti-reflection coating with excellent spreading properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com