Carbon nanotube pre-dispersion for modification of silicone rubber and preparation method thereof

A carbon nanotube and pre-dispersion technology, applied in the field of materials, can solve the problem of reducing the dispersion problem, can not solve the carbon nanotubes and other problems well, and achieves a small amount of addition, important commercial application value, and good stability of silicone rubber. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

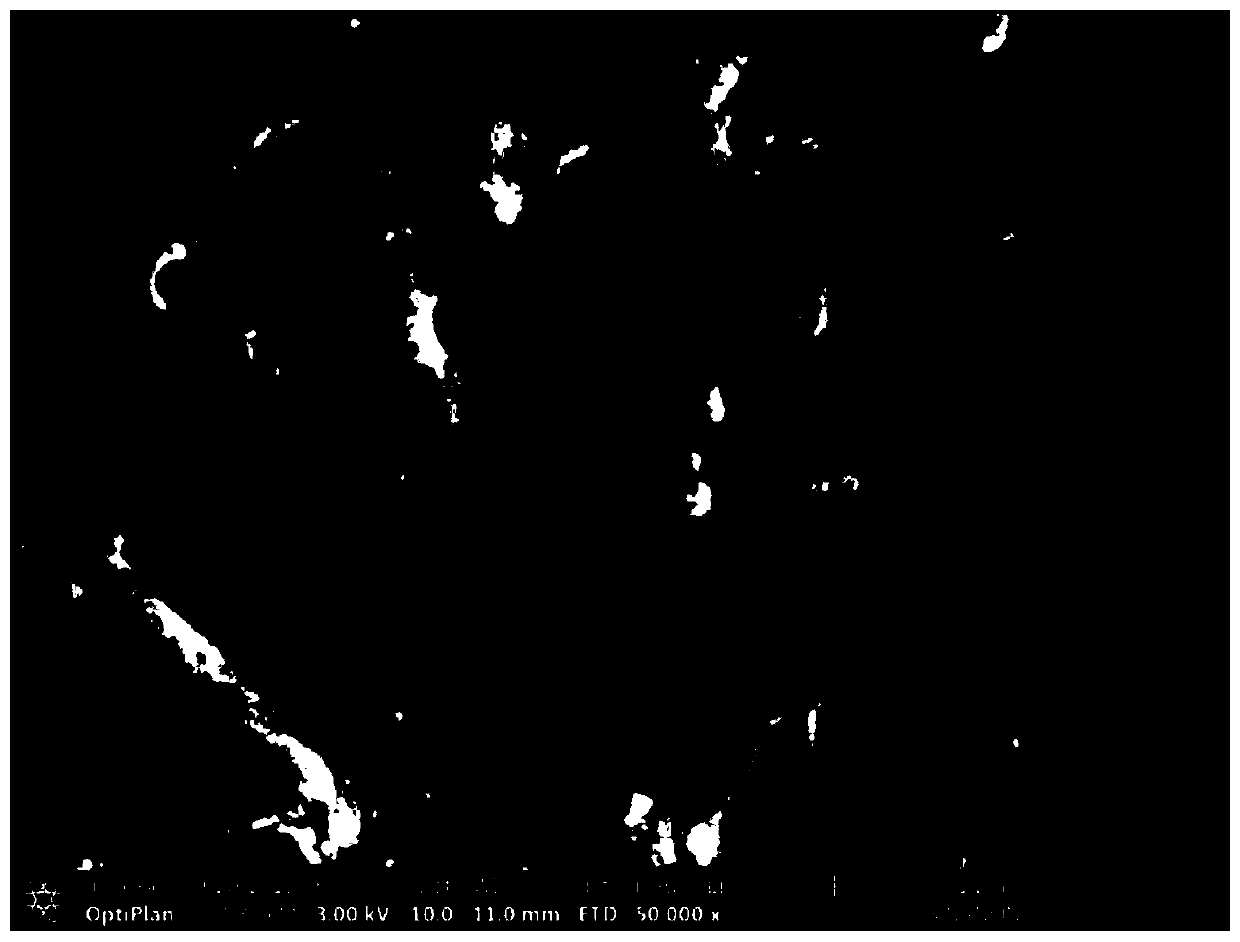

Image

Examples

Embodiment 1

[0048] Step 1: Preparation of carbon nanotube silicone oil predispersion

[0049] First, pour 10g of carbon nanotubes with a weighing diameter of 1-50nm and a length of 0.1-50μm, 70g of silicone oil oligomer, 5g of wetting agent and 15g of dispersing agent into a beaker, and stir with a high-speed mixer for 30 minutes until the mixture is uniform . Secondly, the uniformly mixed primary carbon tube pre-dispersion is subjected to high-strength grinding and shearing by using a CNC three-roller machine, and the entanglement is entangled by changing the speed and roller spacing of the feeding roller, middle roller, and discharging roller of the CNC three-roller machine. The carbon nanotubes are dispersed, and the grinding process parameters of the CNC three-roller machine: the gap between the feeding roller, the middle roller and the discharging roller is 20 μm; the roller speed is 1000rpm and the grinding is repeated once, and finally the carbon nanotubes are obtained. pre-disper...

Embodiment 2

[0053] Step 1: Preparation of carbon nanotube silicone oil predispersion

[0054] First, pour 10g of carbon nanotubes with a weighing diameter of 1-50nm and a length of 0.1-50μm, 70g of silicone oil oligomer, 5g of wetting agent and 15g of dispersing agent into a beaker, and stir with a high-speed mixer for 30 minutes until the mixture is uniform . Secondly, the uniformly mixed primary carbon tube pre-dispersion is subjected to high-strength grinding and shearing by using a CNC three-roller machine, and the entanglement is entangled by changing the speed and roller spacing of the feeding roller, middle roller, and discharging roller of the CNC three-roller machine. The carbon nanotubes are dispersed, and the grinding process parameters of the CNC three-roller machine: the gap between the feeding roller, the middle roller and the discharging roller is 10 μm; the roller speed is 200rpm and the grinding is repeated 5 times, and finally the carbon nanotubes are obtained. pre-disp...

Embodiment 3

[0058] Step 1: Preparation of carbon nanotube silicone oil predispersion

[0059] First, pour 10g of carbon nanotubes with a weighing diameter of 1-50nm and a length of 0.1-50μm, 70g of silicone oil oligomer, 5g of wetting agent and 15g of dispersing agent into a beaker, and stir with a high-speed mixer for 30 minutes until the mixture is uniform . Secondly, the uniformly mixed primary carbon tube pre-dispersion is subjected to high-strength grinding and shearing by using a CNC three-roller machine, and the entanglement is entangled by changing the speed and roller spacing of the feeding roller, middle roller, and discharging roller of the CNC three-roller machine. The carbon nanotubes are dispersed, and the grinding process parameters of the CNC three-roller machine: the gap between the feeding roller, the middle roller and the discharging roller is 30 μm; the roller speed is 400rpm and the grinding is repeated twice, and finally the carbon nanotubes are obtained. pre-disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com