Electrostatic protection ring based on high-voltage process

An electrostatic protection and process technology, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of increasing the current path, breakdown, random damage and increasing the difficulty of integrated circuit design, and achieves improved antistatic level, Enhance the effect of pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

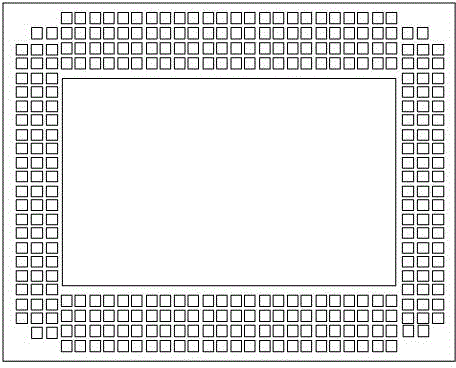

[0014] An electrostatic protection ring based on a high-voltage process according to the present invention includes a first physical layer, a second physical layer, and a plurality of holes connecting the first physical layer and the second physical layer, and is characterized in that the electrostatic protection ring Sharp areas at corners do not have holes.

[0015] When the electrostatic current flows, it flows uniformly from the first physical layer to the second physical layer through all the connected holes. At the corner of the electrostatic protection ring, since there is no hole at the sharp corner, no current flows through the sharp corner, and the corresponding The electric field and electric field line density at the sharp corner are weakened, and the withstand voltage level at the sharp corner is improved.

[0016] Thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com