Casting mold shell boxing and roasting technology

A roasting process and shell packing technology, which is applied to manufacturing tools, casting molding equipment, casting molds, etc., can solve problems such as the impact of casting quality, and achieve the effects of improving molding quality, excellent tear resistance, and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

[0020] Such as figure 1 , figure 2 As shown, the present invention provides a kind of casting mold case packing roasting process, comprises the following steps:

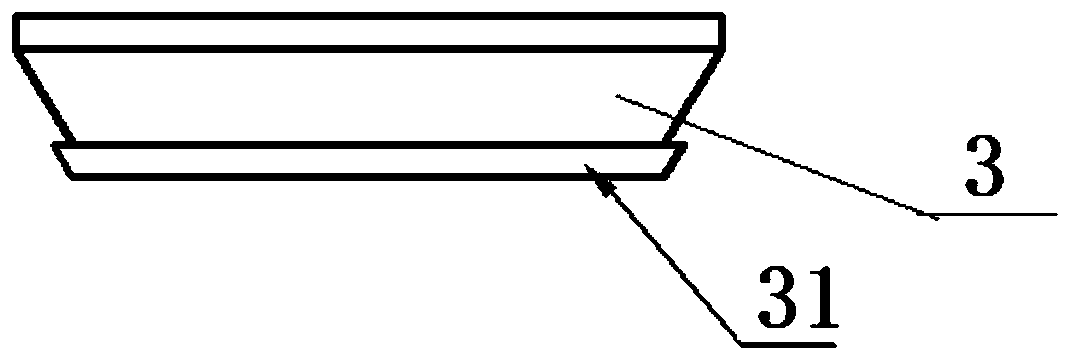

[0021] Provide a casting formwork 1, a sand box 2 and a protective cover 3 with an opening at one end. A sprue cup is arranged on the casting formwork 1. Cover the protective cover 3 at the mouth of the sprue cup, and then place the casting formwork 1 In the sand box 2, fill the refractory sand 4 into the space inside the sand box 2, then take out the casting mold shell 1, remove the protective cover 3, use refractory material to cover the mouth of the sprue cup, and cast the mold shell 1 The shell is obtained after high-temperature calcination. Preferably, the mouth edge of the protective cover 3 is also provided with a curling edge 31 turned towards its outer periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com