Stainless steel pipe cold rolling oil removing device and method

A stainless steel tube and oil sealing technology, which is used in workpiece cleaning devices, metal rolling, metal rolling, etc. oil effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

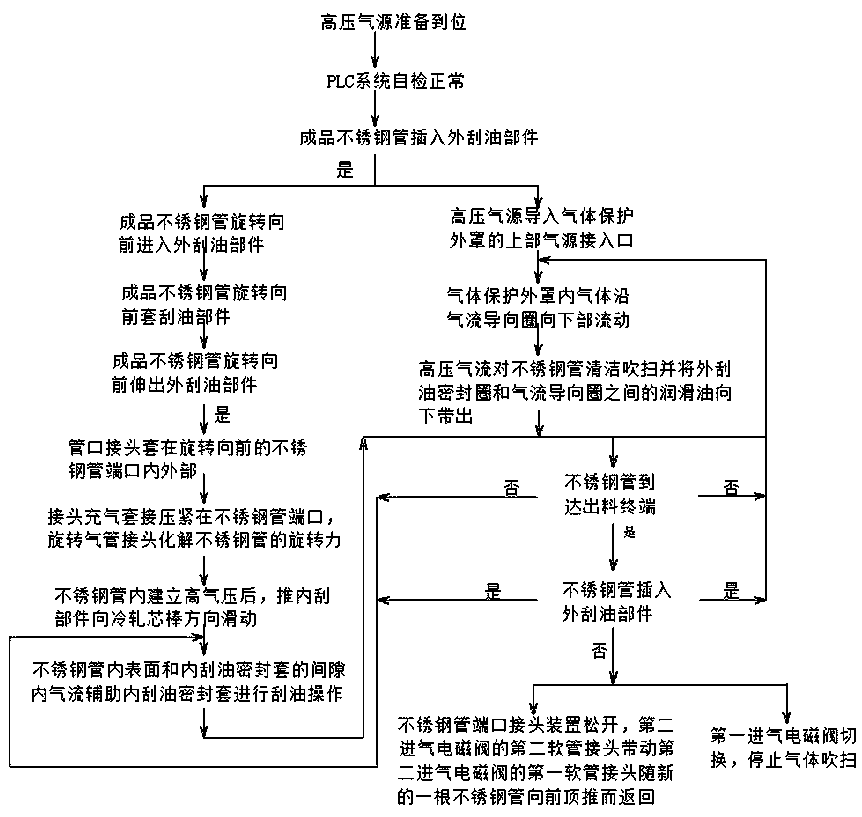

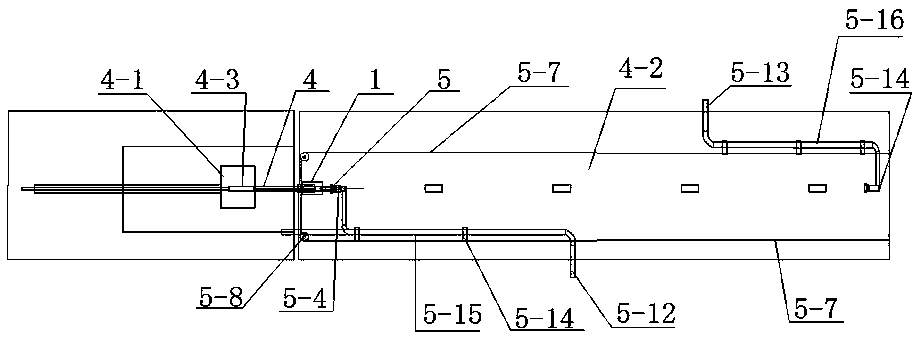

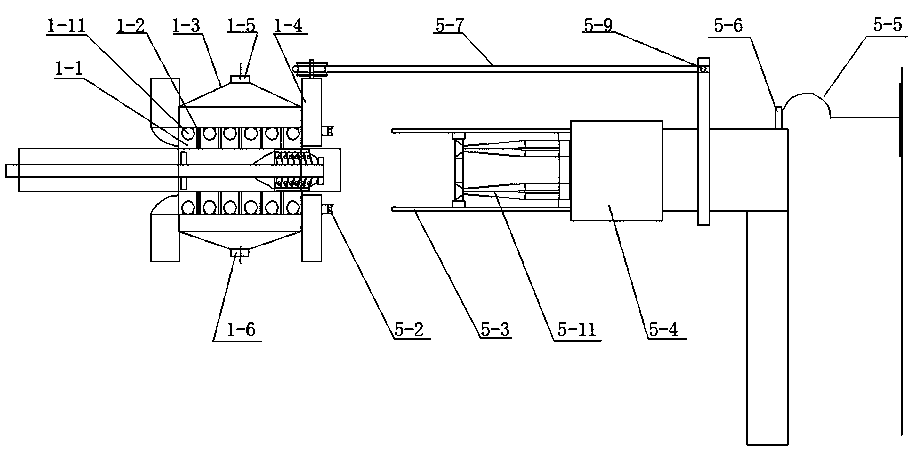

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments, but the protection scope of the present invention is not limited to these embodiments, and all changes or equivalent substitutions that do not depart from the concept of the present invention are included within the protection scope of the present invention.

[0035] The stainless steel pipe cold rolling degreasing process is combined with the stainless steel pipe cold rolling process. When the stainless steel pipe is rolled into a finished product from the stainless steel cold rolling mill, the lubricating oil added during the rolling process is present inside and outside the finished stainless steel pipe. The existence of lubricating oil is inconvenient for the transfer of stainless steel pipes between different processes. If it is not treated or handled improperly, it will cause oil pollution everywhere and affect the environment. Using oil removal can solve the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com