Evaporation cooling integrated equipment

An evaporative cooling and integrated technology, which is applied in the direction of boiler/distillate distillation, etc., can solve the problems of increased labor costs, waste of water resources, environmental pollution, etc., and achieve the effects of reducing evaporation costs, strengthening heat preservation effects, and improving evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

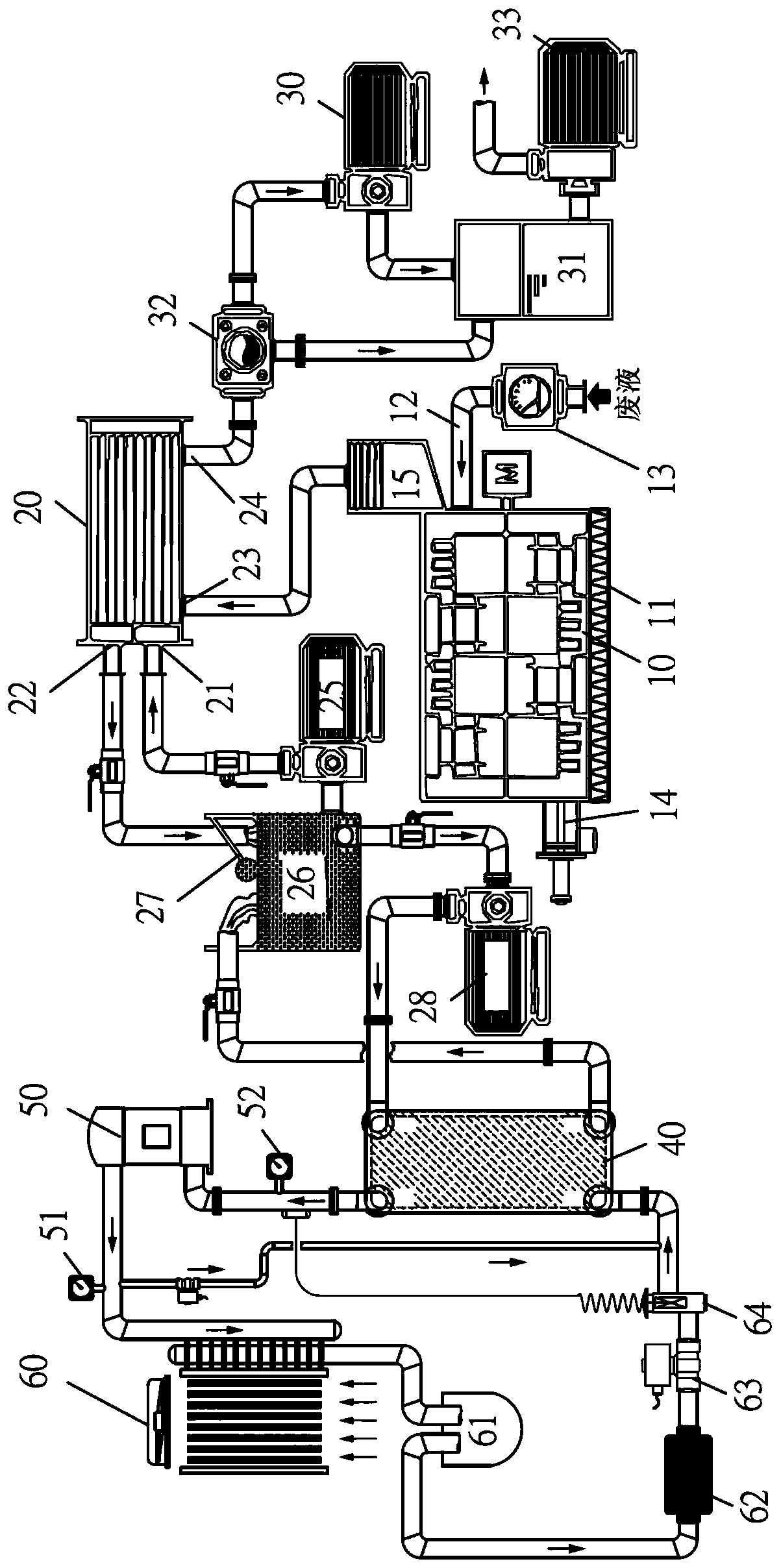

[0021] Example: such as figure 1 As shown, an evaporative cooling integrated equipment includes a still 10, a condenser 20, a heat exchanger 40, a compressor 50 and an air-cooled unit 60, and the still 10 is connected to the water vapor inlet of the condenser 20 through a pipeline. 23. The evaporative and condensed water outlet 24 of the condenser is connected to the second water tank 31 through a pipeline, the condenser 20 is connected to a vacuum pump 30, the cooling water inlet 21 and the cooling water outlet 22 of the condenser are connected to the first water tank 26 connection, the still 10 is provided with a waste liquid pipe 12 and a slag discharge pipe 14, and the compressor 50, the air cooling unit 60, the expansion valve 64 and the heat exchanger 40 are connected by pipelines to form a circulation loop of the refrigerant, After the water in the first water tank 26 enters the heat exchanger 40 through the pipeline and is cooled by the refrigerant, it forms low-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com