Motor protection device for water level control

A protection device and water level control technology, applied in the direction of electromechanical devices, cooling/ventilation devices, electrical components, etc., can solve the problems of endangering the personal safety of workers, reducing the service life of motors, increasing enterprise expenditure, etc., achieving high practicality and safety , High waterproof performance, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

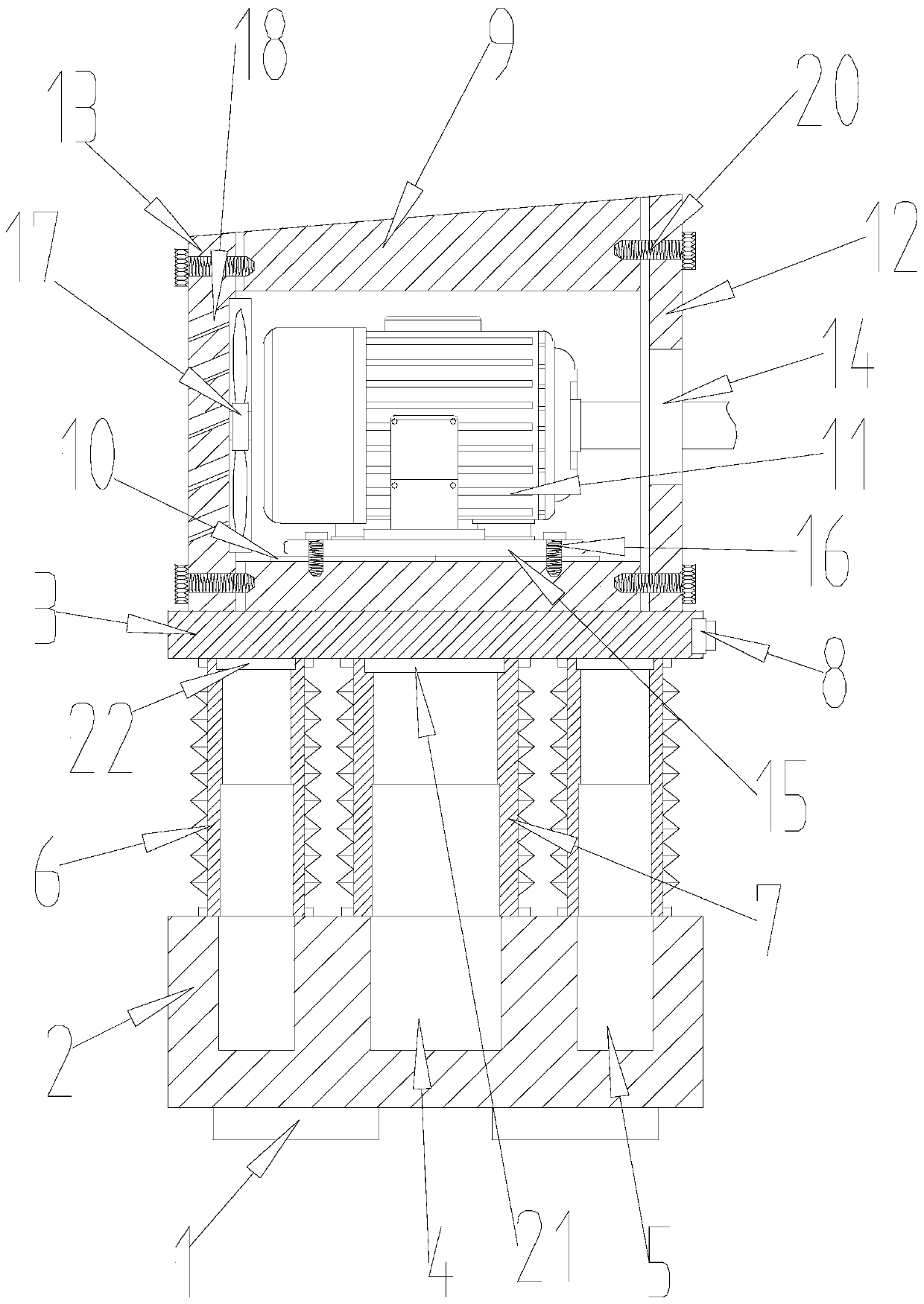

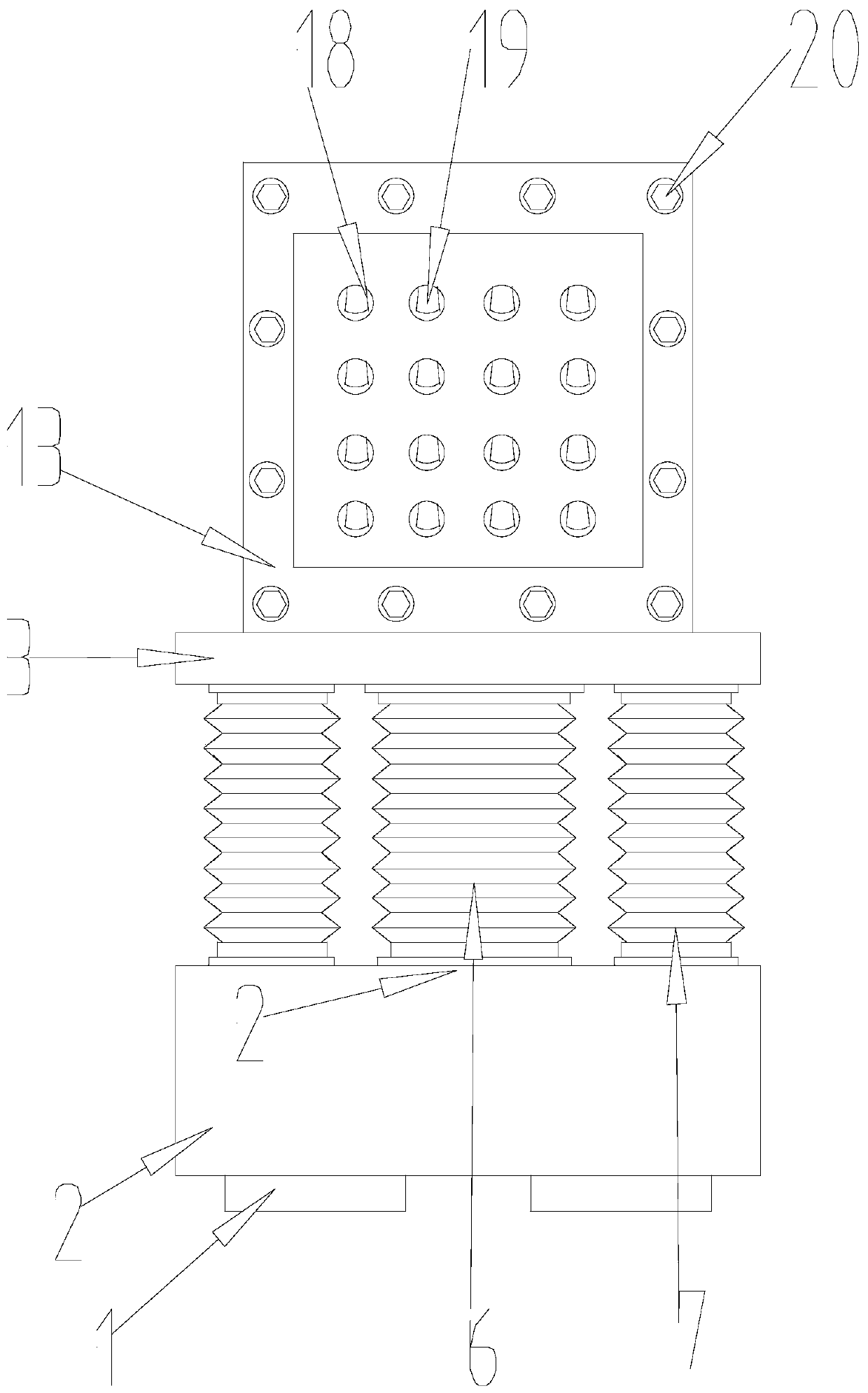

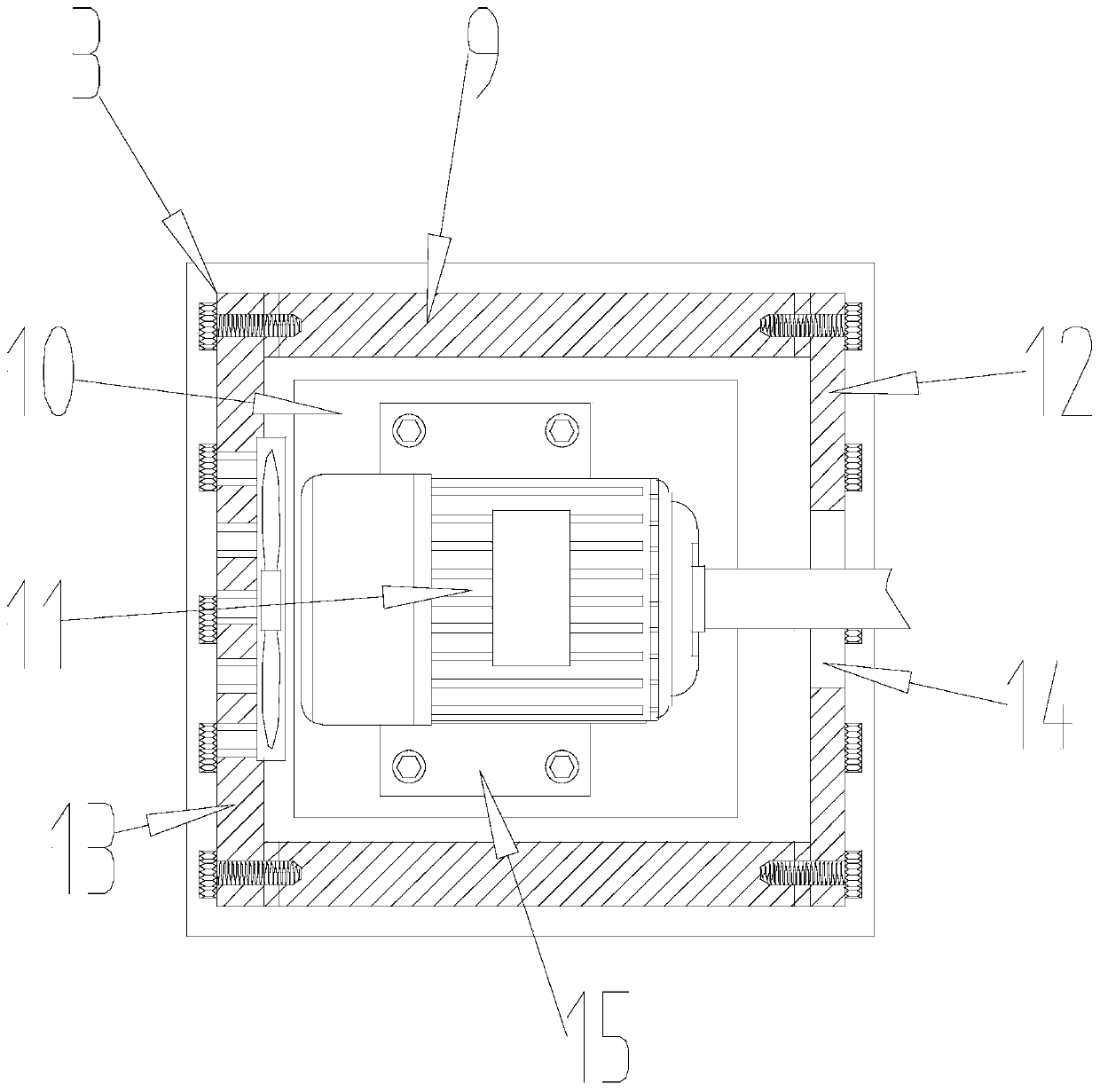

[0030] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7 As shown, a motor protection device for water level control, a motor protection device for water level control, including four legs with the same structure, the four legs are respectively fixed on the ground, and the four legs are installed There are supporting structures and protective structures; the supporting structures are mainly: a base, a bearing plate, a hydraulic cylinder, four telescopic rods with the same structure, a first waterproof sleeve, a second waterproof sleeve and a water level sensor; the lower wall of the base Placed on four legs, the base is provided with a first groove and four second grooves with the same structure, the hydraulic cylinder is placed in the first groove of the base, and the bearing plate is placed on On the telescopic ends of the hydraulic cylinder and the four telescopic rods, the four telescopic rods are respectively pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com