Wavelength Tuning of ZnSe Quantum Dots Using In3+ Salts as Dopants

一种铟掺杂、发射波长的技术,应用在纳米领域,能够解决不能制成纯ZnSe、光致发光量子产率受损等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

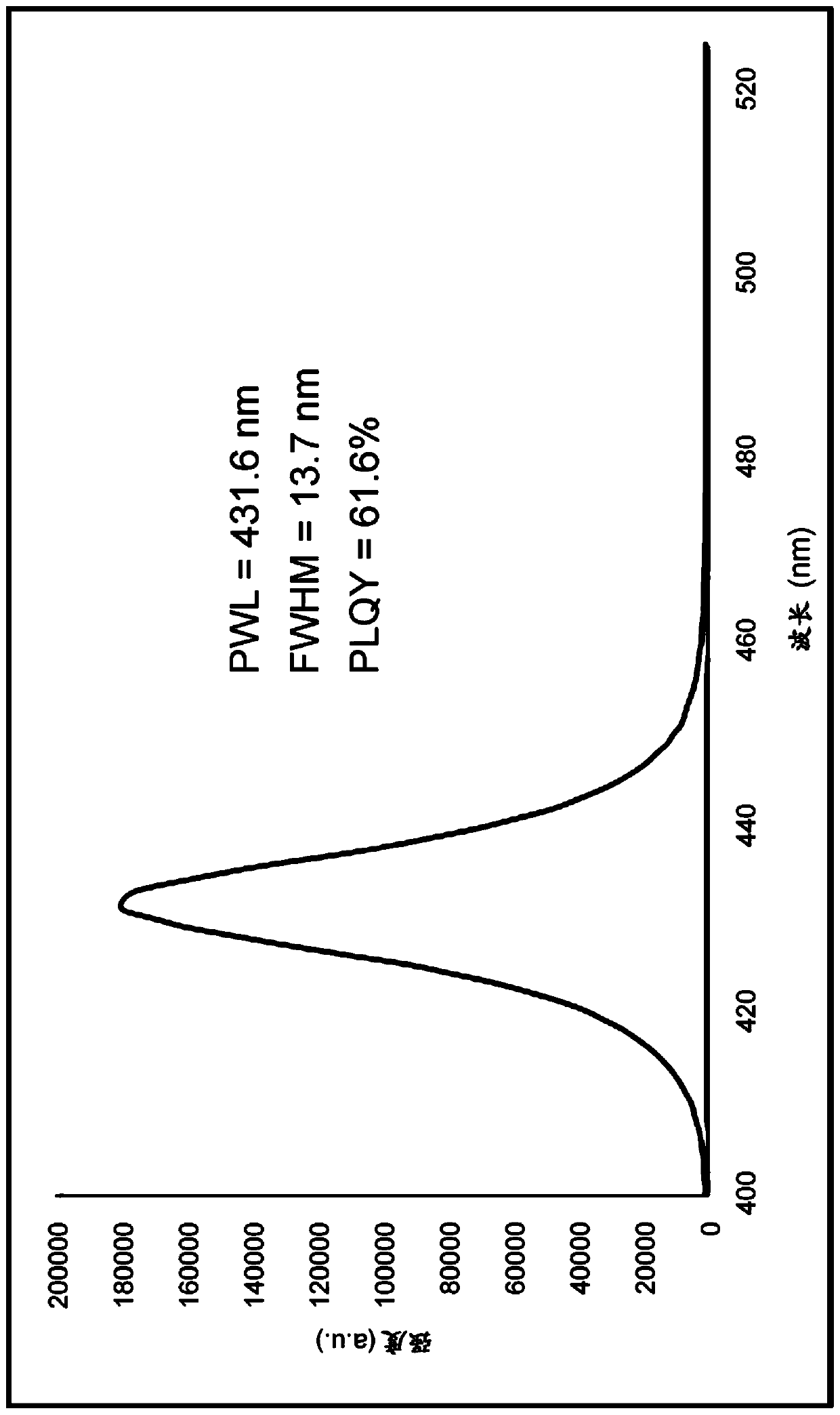

[0246] InCl 3 -Synthesis of doped ZnSe nanostructures

[0247] Oleylamine (15 mL) was added to a 100 mL three-necked flask and vacuum degassed at 110° C. for 30 minutes. The mixture was heated to 300°C under nitrogen flow. At this temperature, 1.5 mL of a solution of trioctylphosphine selenide (TOPSe, 1.92M) and diphenylphosphine (225 μL) in trioctylphosphine (TOP, 1.0 mL total) was added to the flask. Once the temperature rebounded to 300°C, diethylzinc (295 μL) in TOP (2.5 mL) and indium chloride (8 mg, 36 μmol) in TOP (2.5 mL) were injected rapidly. The temperature was set at 280°C and after 5 min a solution of diethylzinc (1.38 mL) and 10.5 mL of TOPSe (1.92M) in TOP (total 6.5 mL) was fed at a rate of 1 mL / min. Stop for 10 minutes after 7.5 mL, and stop for 15 minutes after 9.5 mL. Starting 26 minutes after the zinc infusion, additional oleylamine (20 mL) was infused at a rate of 1.5 mL / min. After the infusion was complete, the reaction mixture was maintained at 280°...

Embodiment 2

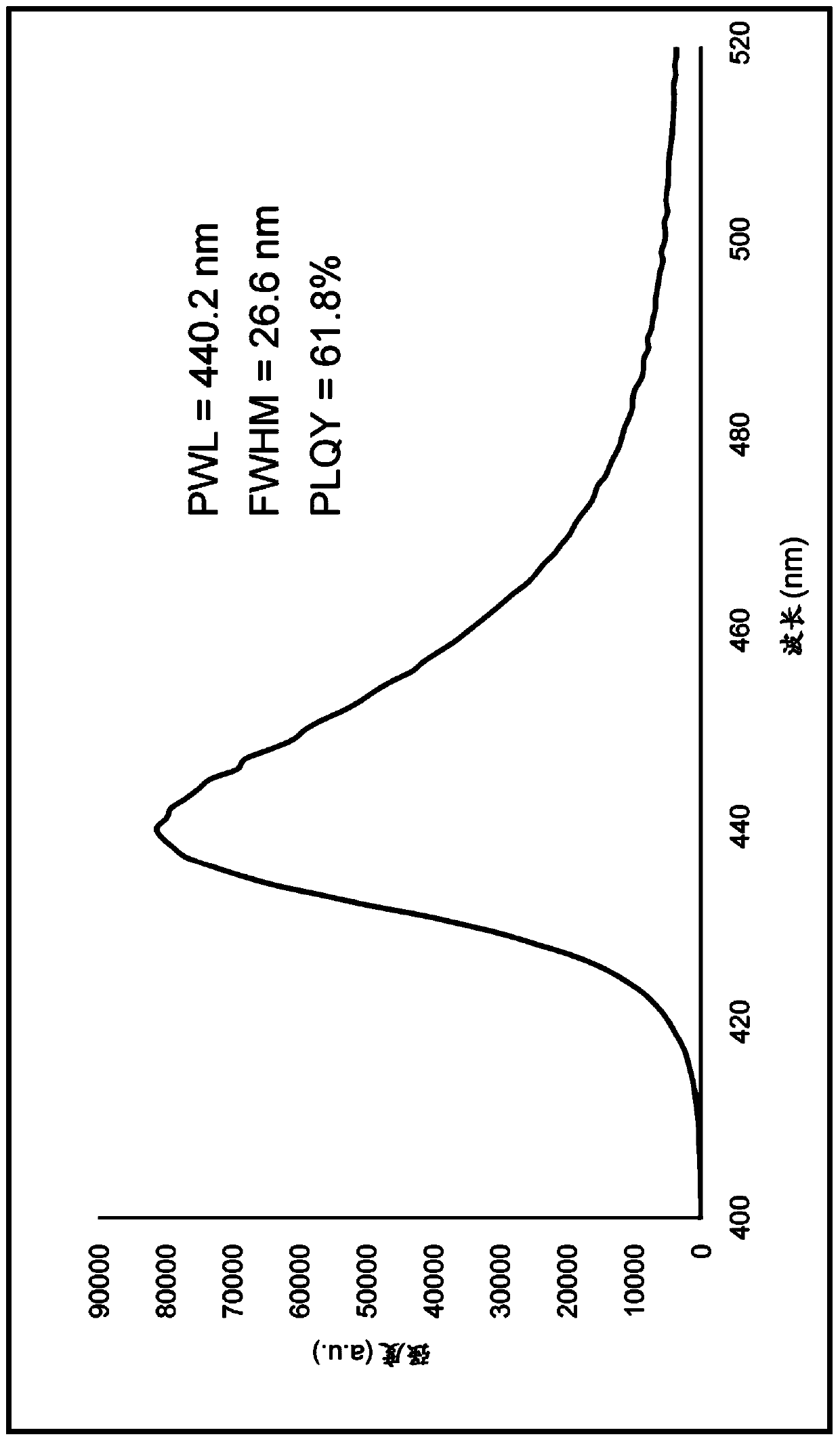

[0249] InCl 3 Synthesis of Doped ZnSe / ZnSe / ZnS Core / Buffer / Shell Nanostructures

[0250] InCl with an average diameter of 4.0 nm with 4ML ZnSe buffer layer and 6ML ZnS using the following procedure 3 The ZnSe / ZnS buffer layer / shell is coated on the doped ZnSe nanocrystal core.

[0251] Into a 100 mL three-necked flask were added zinc oleate (6.03 g), lauric acid (3.85 g) and trioctylphosphine oxide (4.93 g). After three cycles of vacuum and nitrogen backfill, TOP (9.9 mL) and InCl 3 A solution of doped ZnSe cores (1.5 mL, 78.9 mg / mL in toluene) was added to the flask. The solution was degassed under vacuum at 100°C for 20 minutes, then heated to 310°C under nitrogen flow. Ten minutes after reaching this temperature, a slow infusion of TOPSe (9.5 mL, 0.3 M in TOP) was started at a rate of 0.19 mL / min. After the selenium infusion was complete, the reaction was maintained at 310°C for 10 minutes. An infusion of tributylphosphine sulfide (16.9 mL, 0.4M in TOP) was then start...

Embodiment 3

[0253] Synthesis of Indium-doped ZnSe Nanostructures

[0254] Indium-doped ZnSe nanostructures can be prepared using the procedures in Examples 1-2 using various indium salts. The amounts and resulting optical properties of the indium-doped ZnSe / ZnS core / shell nanostructures are provided in Table 1.

[0255] Table 1

[0256]

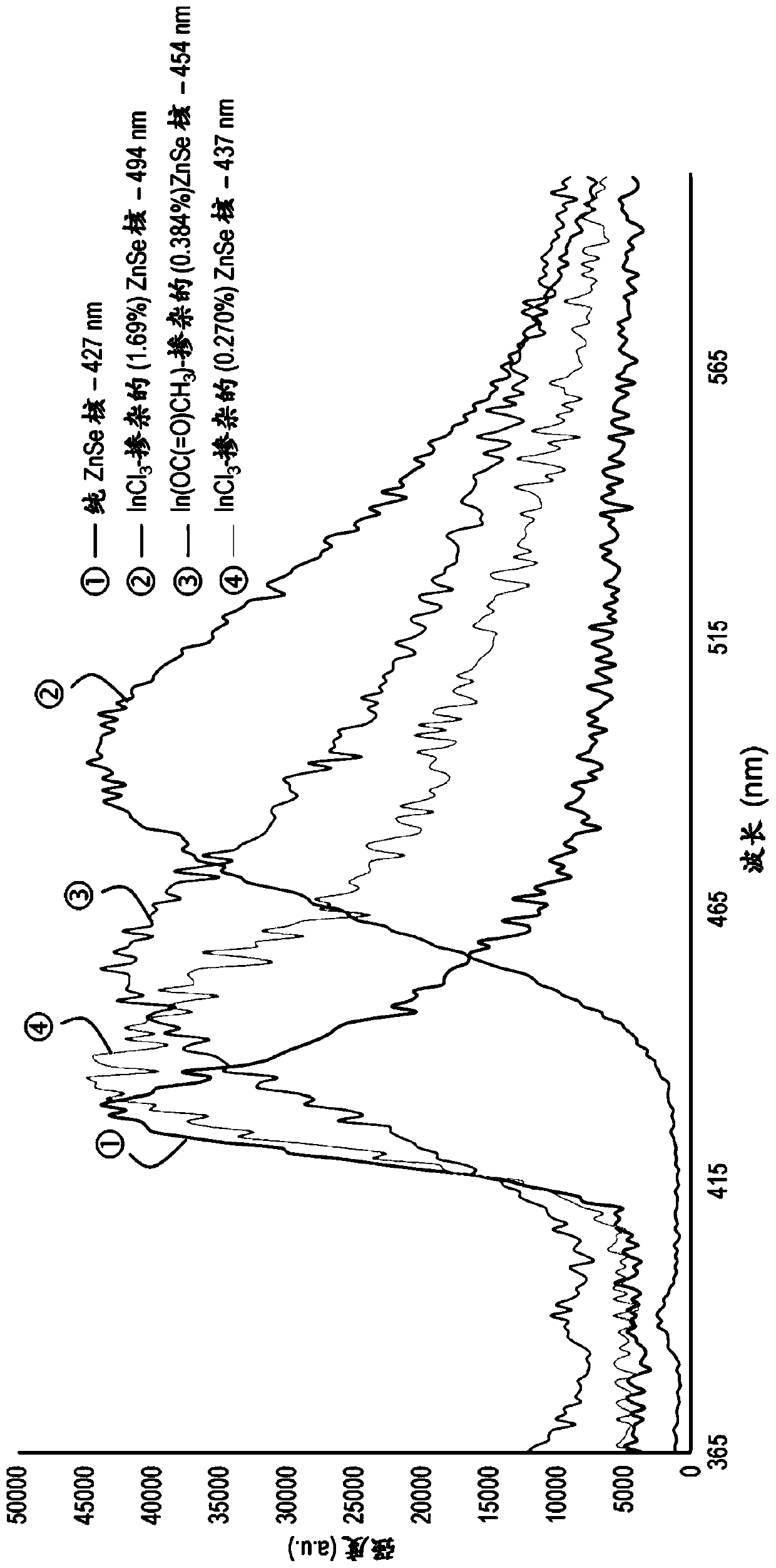

[0257] as table 1 and figure 1 As shown, the PWL of indium-doped ZnSe core and ZnSe / ZnSe / ZnS core / buffer / shell nanostructures can be tuned by varying the amount and type of indium salt used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence wavelength | aaaaa | aaaaa |

| fluorescence wavelength | aaaaa | aaaaa |

| fluorescence wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com