A fully automatic high-speed welting machine for filter elements

A fully automatic and welting machine technology, applied in the field of automation, can solve the problems of high production cost and low work efficiency, and achieve the effects of saving costs, improving production efficiency, and quick and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

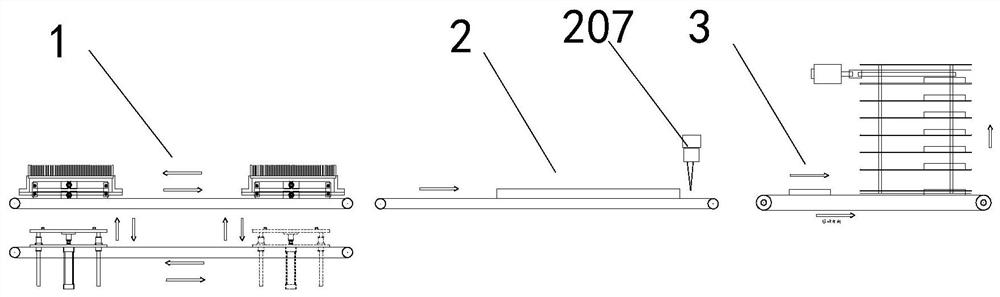

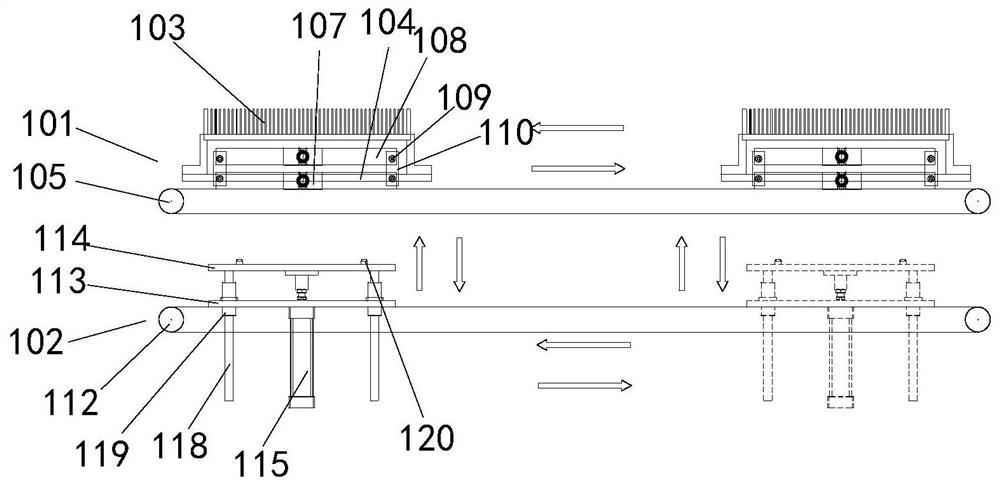

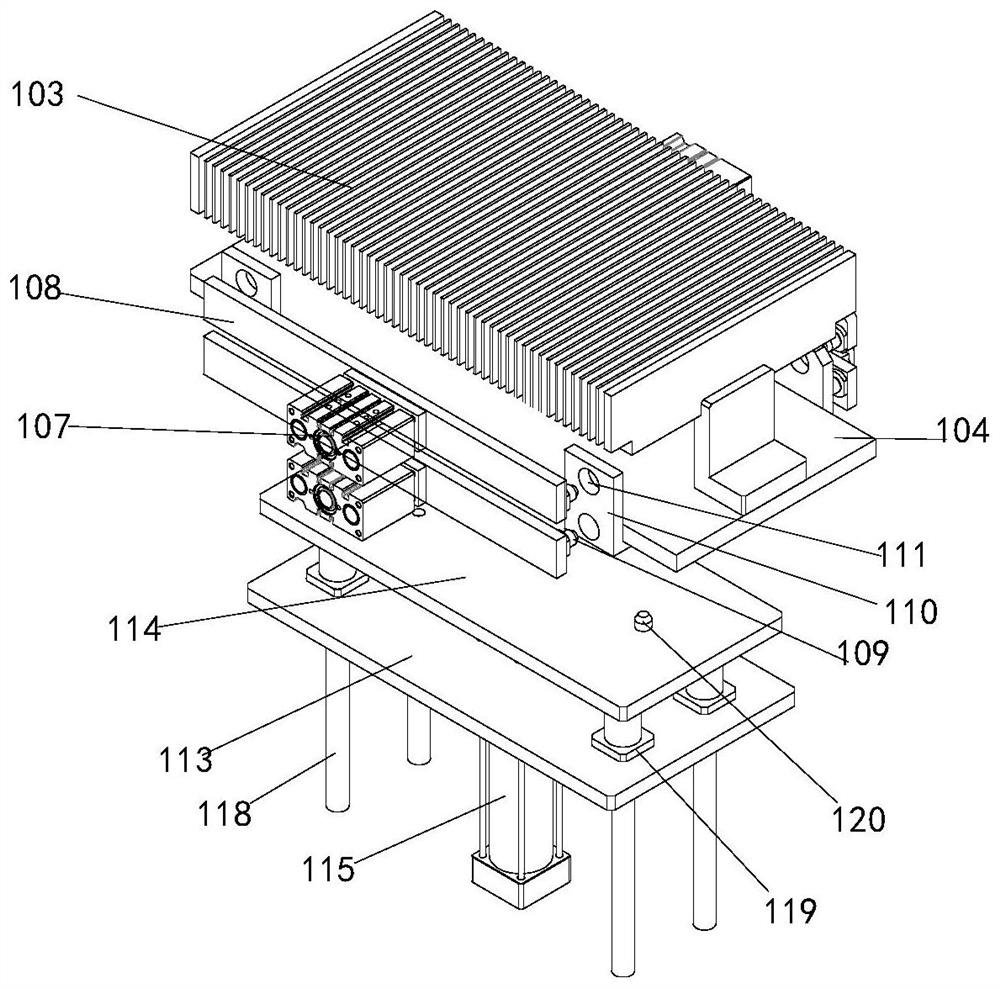

[0043] Example: such as figure 1 As shown, a full-automatic high-speed welting machine for filter elements includes a product shaping mold circulation conveying device 1, a product continuous welting device 2 and a product multi-layer cooling device 3, and the product shaping mold circulation conveying device 1 is the first processing procedure. The product continuous welting device 2 is the second processing procedure, and the product multi-layer cooling device 3 is the third processing procedure; the main work flow of the filter element product manufacturing line designed in this scheme is: the first procedure is to put the filter cloth into In the empty groove of the mold plate 103 of the product shaping mold circulation conveying device 1, the filter cloth is shaped into a wave-bent shape through processing, and then the wave-bent filter cloth is sent to the second process product continuous welting device 2 Inside, the side strips 202 coated with hot melt adhesive are att...

Embodiment approach

[0048] Such as Figure 4~5 As shown, the product delivery mechanism 101 also includes two left and right first rails 116 that are parallel to each other, and the mobile connecting plate 106 is movably arranged on the first rail 116; the mold return mechanism 102 also includes two left and right second parallel rails. The track 117 and the movable bottom plate 113 are movably arranged on the second track 117. Two sets of guide posts 118 are correspondingly arranged on the left and right sides of the second cylinder 115, and the two corresponding guide posts 118 pass through the linear bearing 119 and the lifting plate respectively. The left and right sides of 114 are connected; the left and right two parallel first rails 116 can ensure that the left and right moving connecting plates 106 always move forward and backward in a straight line. The left and right balance of the mold plate 103 can be improved; the left and right two parallel second rails 117 can ensure that the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com