Vertical air-cooled double-cylinder permanent magnet speed regulator

A technology of permanent magnet speed governor and cold double cylinder type, which is applied in the direction of permanent magnet clutch/brake, asynchronous induction clutch/brake, cooling/ventilation device, etc., which can solve high maintenance cost, low magnetic field utilization rate, equipment The problem of heavy weight, etc., achieves the effect of convenient installation, commissioning and maintenance, high utilization rate of magnetic field, simple and effective structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

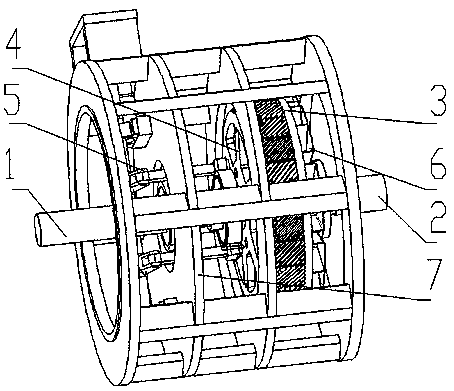

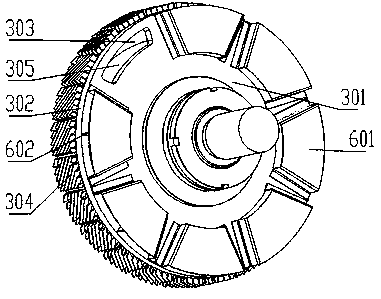

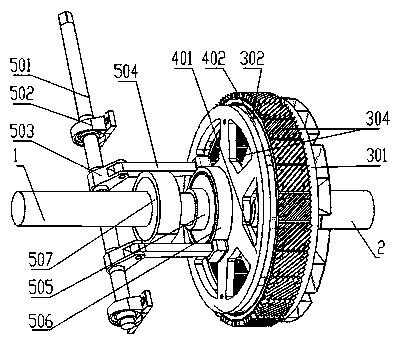

[0026] see Figure 1-Figure 4 , a vertical air-cooled double-tube permanent magnet speed governor, including a permanent magnet rotor assembly 4 arranged on the load shaft 1, a conductor rotor assembly 3 arranged on the motor input shaft 2 and a speed regulating mechanism 5, the permanent magnet The rotor assembly 4 and the conductor rotor assembly 3 are arranged concentrically, the speed regulating mechanism 5 is arranged on the casing, the speed regulating mechanism 5 is far away from the permanent disk 401, and a rotating shaft 501 is arranged on the casing, and two rocker arms 503 are arranged on the rotating shaft 501. The outer ends of the rocker arms 503 are all hinged with one end of the connecting rod 504;

[0027] It also includes a sliding sleeve 505 on which a bearing one 506 is arranged, the other end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com