Light-transmitting structure and manufacturing method of sign stand

A technology of light-transmitting structure and manufacturing method, which is applied in the direction of illuminated signs, instruments, display devices, etc., and can solve the problems of aesthetics, structure, and construction safety of resin luminous characters. The post-maintenance is not particularly good, waste of resources, and product scrapping and other issues, to achieve the effect of clear and simple production method, convenient transportation and installation, and guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

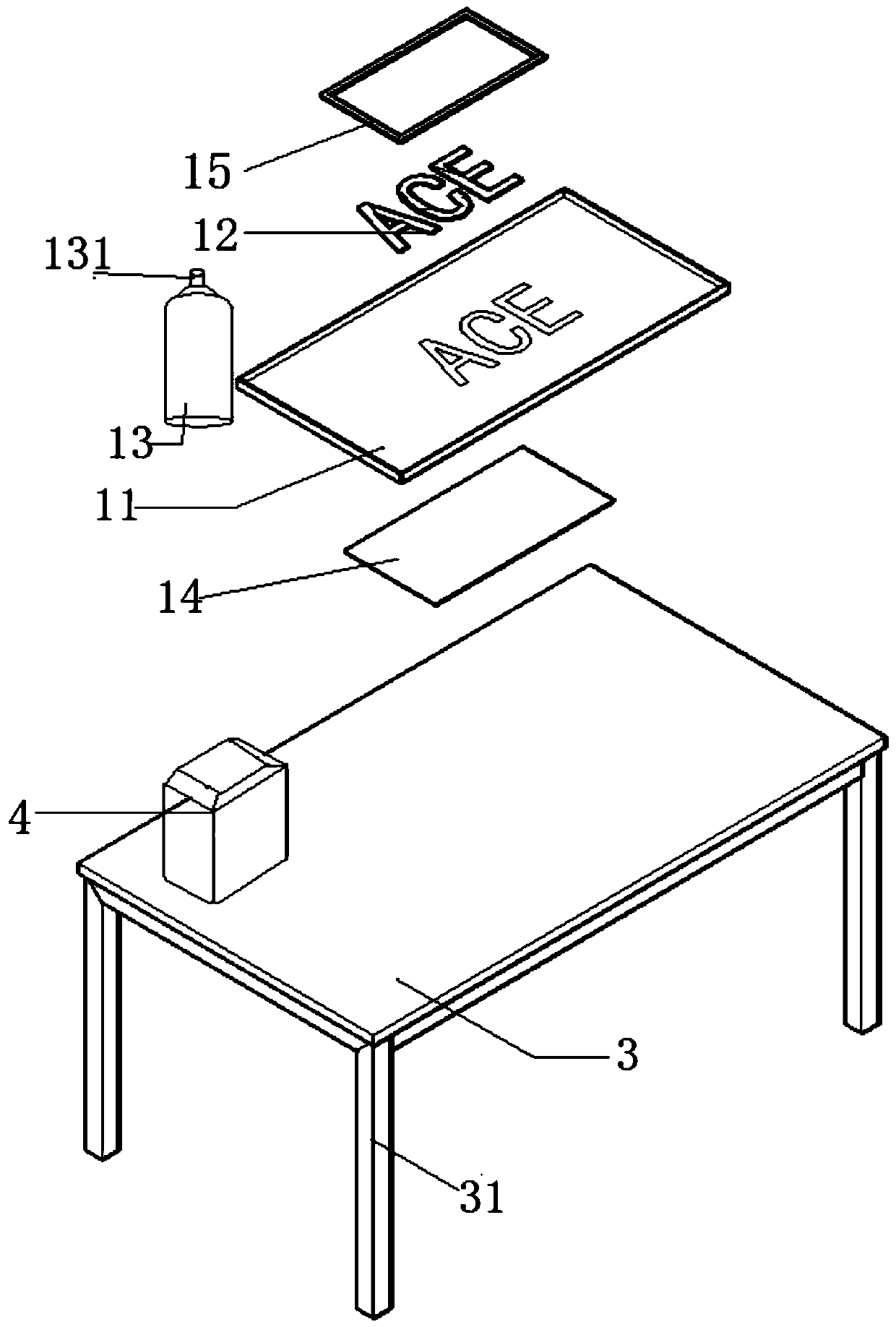

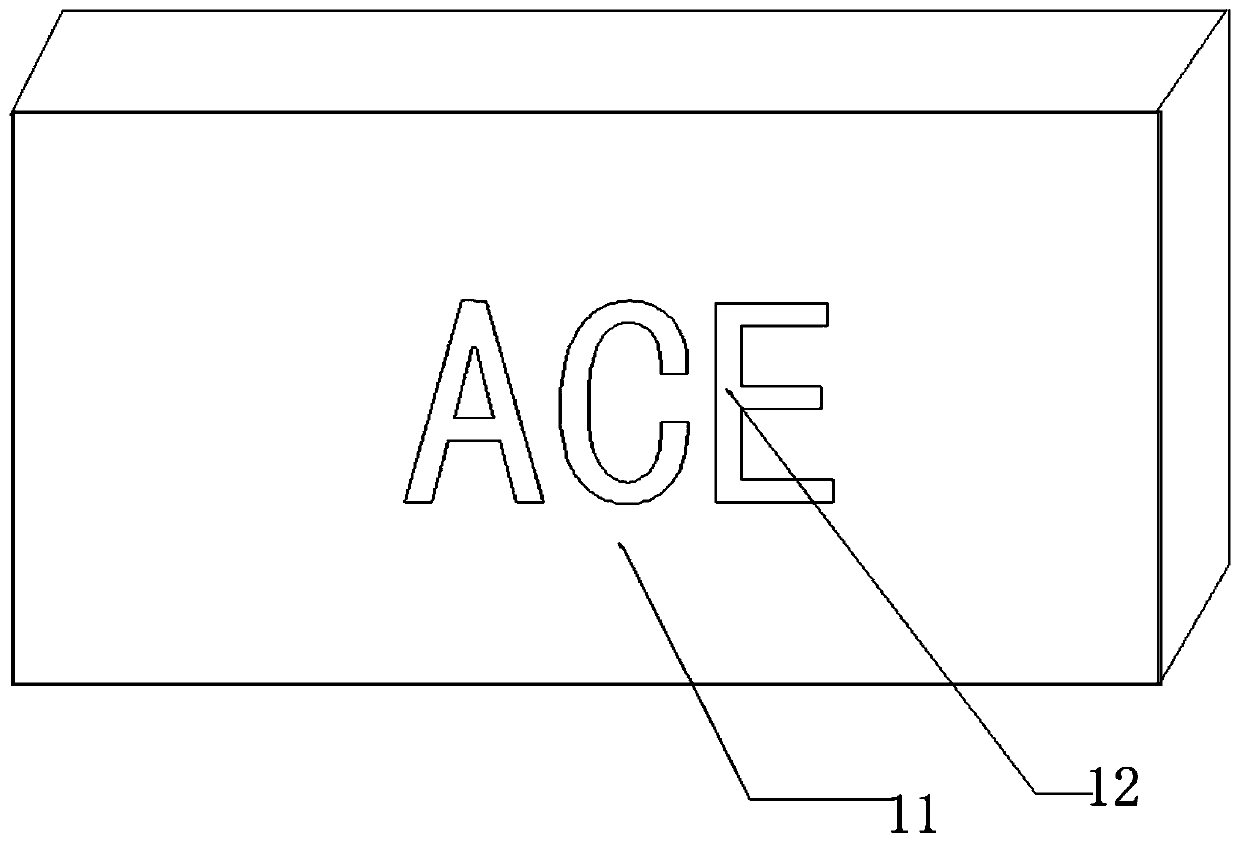

[0069] Embodiment 1: This embodiment is to enumerate the structure and production method and instructions for making a logo standing sign that the uppercase letters are ABC:

[0070] A hollowed-out font 111 of ABC is provided on the signboard 11 of the present embodiment, and an acrylic font plate 12 having the same thickness as the hollowed-out font 111 is arranged on the top of the signboard 11, and the acrylic letterboard is in the shape of ABC ;

[0071] Its production methods mainly include:

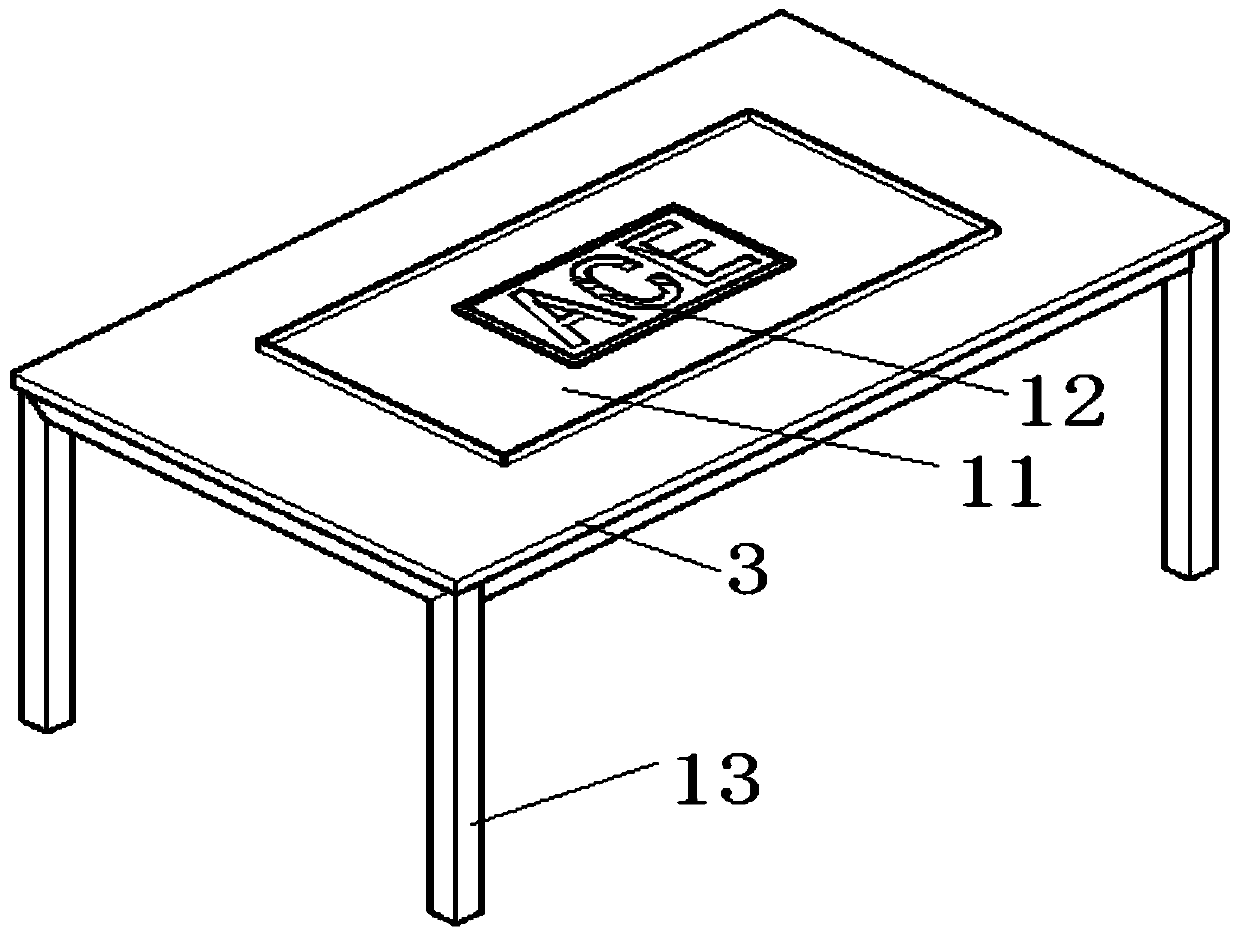

[0072] Step 1) Laminate the logo standing plate 11 with the hollow English font ABC: put the front of the logo standing plate 11 facing up, then place the logo standing plate 11 on the horizontal operating table 3, and pass the film The piece 14 is covered on the front of the logo stand board 11, covering the hollow English font ABC on the logo stand board 11;

[0073] Step 2) Carry out mosaic processing on the logo standing board 11 with the hollowed-out English font ABC: Turn th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com