Shield tunneling machine with ring edge cutters

A technology of cutting edge cutters and shield machines, which is applied in mining equipment, earthwork drilling, tunnels, etc. It can solve the problems of heavy stress on the cutter head and each cutting knife, difficult-to-cut tunnel wall effects, and large energy loss, etc., to achieve The cutting effect is good, the amount of grout injected after the pipe wall is saved, and the energy loss is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] specific implementation plan

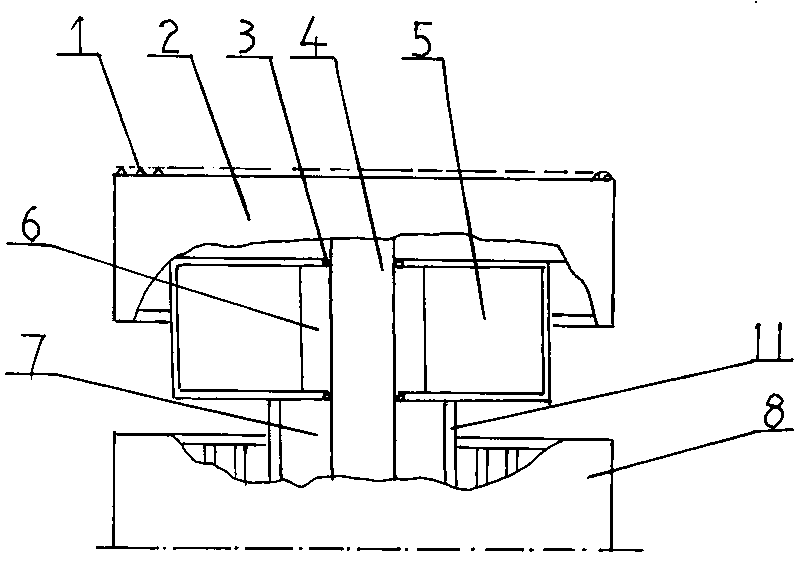

[0033] Such as Figure 1 to Figure 8 As shown, a shield machine with a ring trimming knife includes a body 8, a transmission shaft 4, an excavation box 5, a conveyor belt 7, a knife holder shell 2 and a cutting knife 1. Since the present invention is an improvement on the traditional shield machine, the machine body, the drive shaft that drives the tool holder shell and the cutter head 22 and the multiple cutting knives on it, the bearing pair 3, and the excavation box that receives the cutting dregs at the rear side of the cutter head And the excavation opening 6 that communicates with the conveyor belt, the conveyor belt support frame 11 etc. are traditional shield machine structures, so no longer repeat.

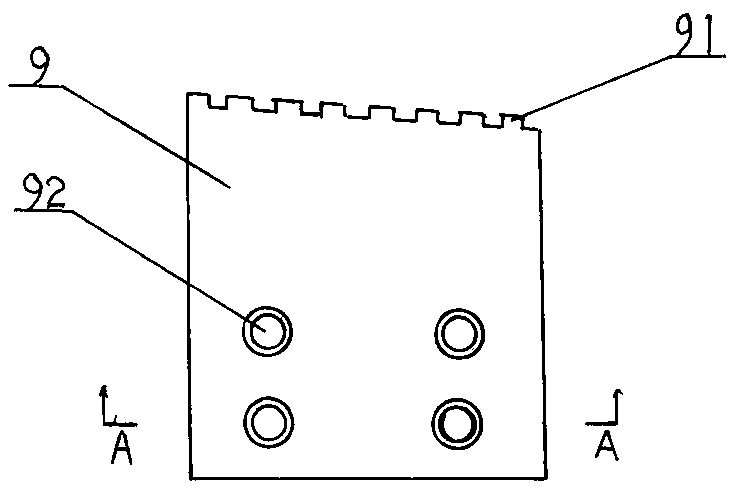

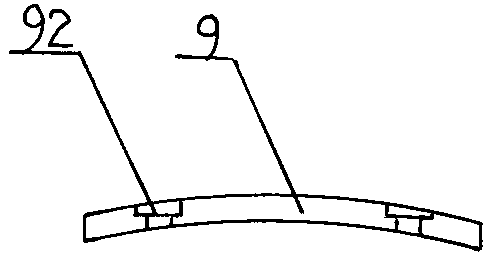

[0034] The present invention is provided with several ring edge cutters 9 at intervals on the front end side of the tool holder housing; or several ring edge cutters are arranged at intervals on the side of the cutter head; Several ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com