Building connecting node and construction method thereof

A technology for connecting nodes and construction methods, used in buildings, building components, building structures, etc., can solve the problems of difficult operation of construction methods, and no specific solutions are proposed, so as to meet operational feasibility, avoid linear cracks, increase safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

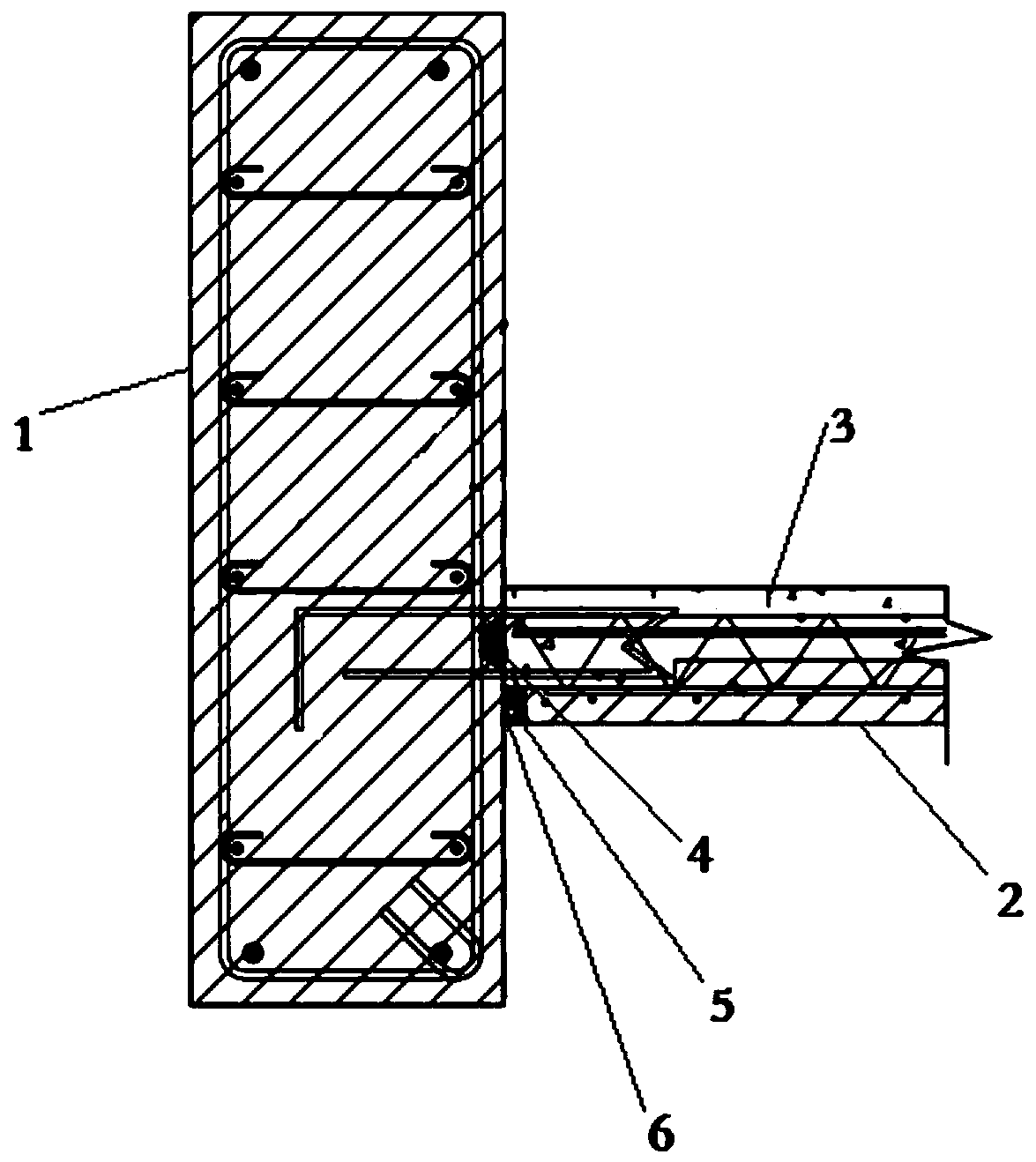

[0038] A building connection node, including a prefabricated part, a cast-in-place part, a connecting part and a sealing part, and the prefabricated part forms a fixed connection through the connecting part, and forms an integral structure with the cast-in-place part and performs sealing treatment through the sealing part; The prefabricated laminated board and the cast-in-place part can form a building floor, and the cast-in-place part is arranged above the prefabricated laminated board.

[0039] Wherein, the prefabricated part includes prefabricated columns, prefabricated beams and prefabricated laminated slabs, and the prefabricated beams include prefabricated turning beams, prefabricated turning frame beams and prefabricated turning beams, and the prefabricated columns are respectively connected with the prefabricated turning beams and the prefabricated turning beams. The two ends of the prefabricated overturning frame beam are fixedly connected; the two ends of the prefabrica...

Embodiment 2

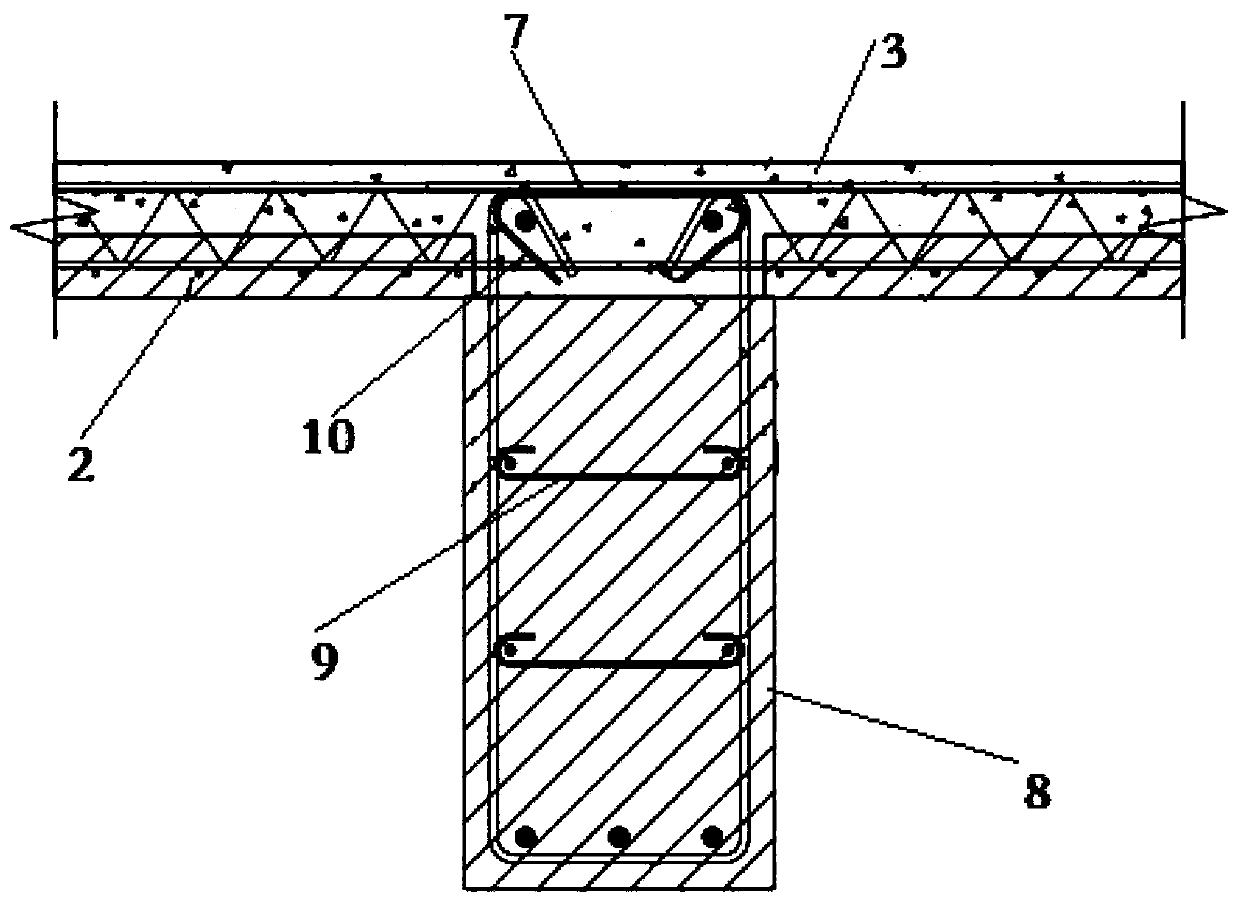

[0047] A building connection node, including a prefabricated part, a cast-in-place part, a connecting part and a sealing part, and the prefabricated part is fixedly connected through the connecting part, and after forming an integral structure with the cast-in-place part, the sealing process is performed through the sealing part; The prefabricated laminated board and the cast-in-place part can form a building floor, and the cast-in-place part is arranged above the prefabricated laminated board.

[0048] The prefabricated part includes prefabricated columns, prefabricated beams and prefabricated laminated slabs, and the prefabricated beams include prefabricated turning beams, prefabricated turning frame beams and prefabricated turning beams, and the prefabricated columns are respectively connected with the prefabricated turning beams and the prefabricated turning beams. The two ends of the overturning frame beam form a fixed connection; the two ends of the prefabricated overturn...

Embodiment 3

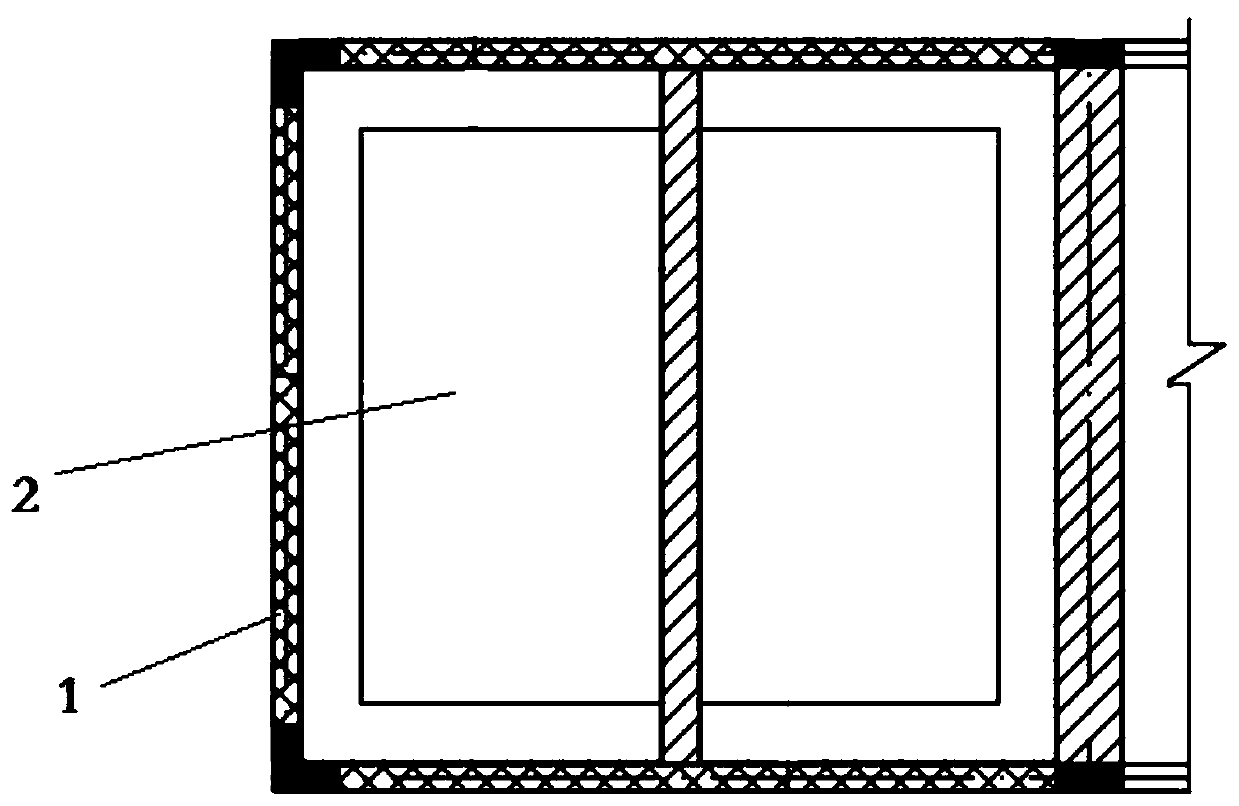

[0059] A building connection node, including a prefabricated part, a cast-in-place part, a connecting part and a sealing part, and the prefabricated part is fixedly connected through the connecting part, and after forming an integral structure with the cast-in-place part, the sealing process is performed through the sealing part; The prefabricated laminated board and the cast-in-place part can form a building floor, and the cast-in-place part is arranged above the prefabricated laminated board.

[0060] The prefabricated part includes prefabricated columns, prefabricated beams and prefabricated laminated slabs, and the prefabricated beams include prefabricated turning beams, prefabricated turning frame beams and prefabricated turning beams, and the prefabricated columns are respectively connected with the prefabricated turning beams and the prefabricated turning beams. The two ends of the overturning frame beam form a fixed connection; the two ends of the prefabricated overturn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com