Antifouling exterior wall glaze and preparation method thereof

An anti-fouling and silicone technology, applied in the field of coatings, can solve the problems of poor stain resistance, insufficient weather resistance, poor heat insulation performance, etc., and achieve the effects of dense film formation, good water resistance, and small taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

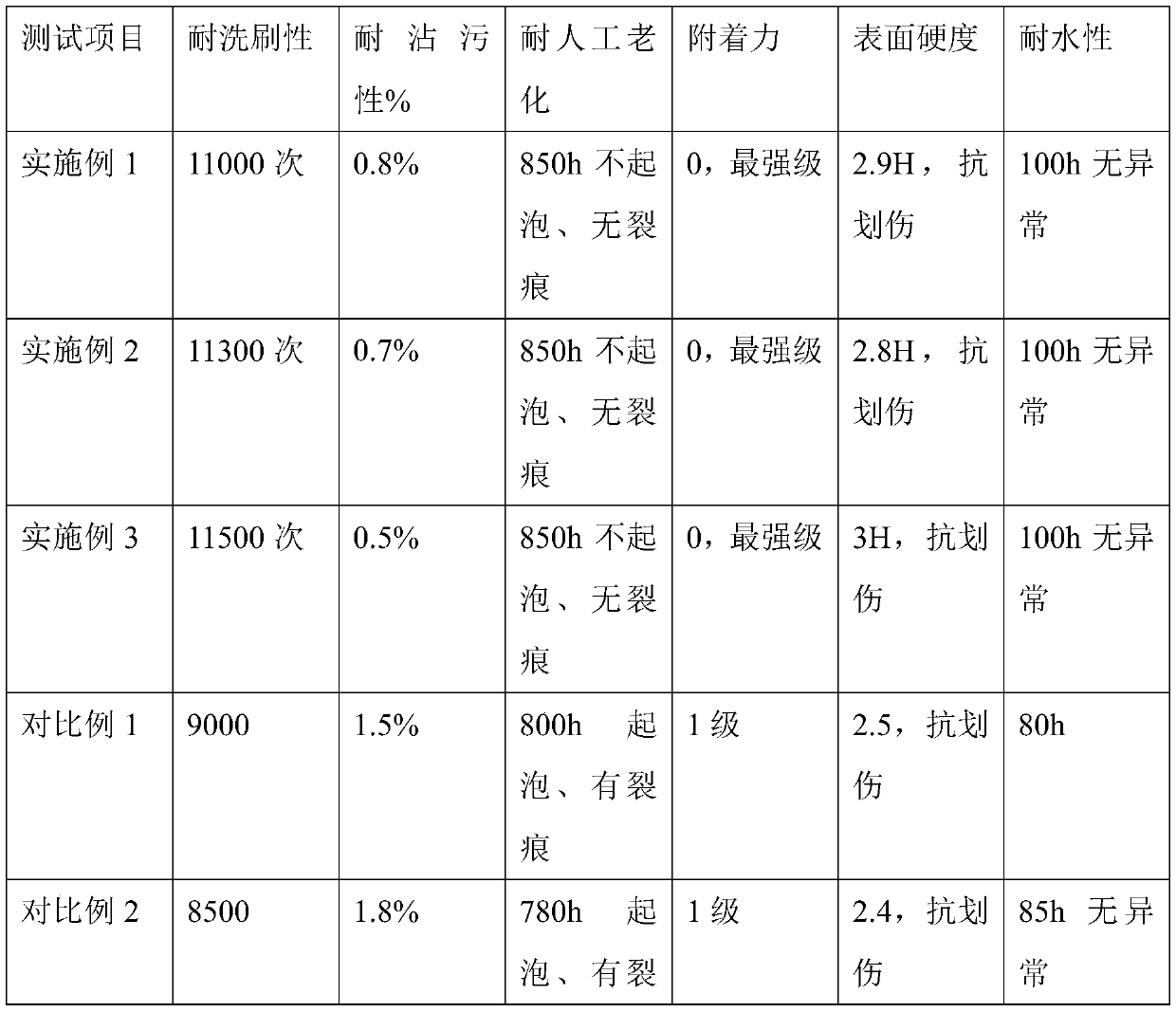

Examples

Embodiment 1

[0026] An antifouling exterior wall glaze, comprising the following components in parts by weight: 2 parts of fluorine-containing acrylic modified polyurethane resin, 2 parts of fluorine-containing acrylic modified silicone resin, 5 parts of nano silicon dioxide, and 5 parts of nano calcium carbonate , 30 parts of alcohol-soluble silicone acrylic resin, 18 parts of dibutyltin dilaurate, 0.5 parts of defoamer, 1 part of dispersant, 20 parts of deionized water, 10 parts of propanol, 1 part of inorganic pigment, 10 parts of porous powder quartz , 1 part of leveling agent and 0.5 part of accelerator.

[0027] A method for preparing an antifouling exterior wall glaze, comprising the following steps:

[0028] (1) Grinding the porous powder quartz and the inorganic pigment and then adding to the solvent and stirring;

[0029] (2) mixing and stirring alcohol-soluble organic silicon acrylic resin, nano silicon dioxide, nano calcium carbonate, fluorine-containing acrylic modified polyu...

Embodiment 2

[0032] An antifouling exterior wall glaze, comprising the following components in parts by weight: 50 parts of alcohol-soluble silicone acrylic resin, 7 parts of nano silicon dioxide, 8 parts of nano calcium carbonate, 5 parts of fluorine-containing acrylic modified polyurethane resin, 5 parts of fluoroacrylic acid modified silicone resin, 45 parts of dibutyltin dilaurate, 1 part of defoamer, 3 parts of dispersant, 50 parts of deionized water, 4 parts of inorganic pigment, 30 parts of porous powder quartz, 5 parts of leveling agent 3 parts and 3 parts of accelerator.

[0033] A method for preparing an antifouling exterior wall glaze, comprising the following steps:

[0034] (1) Grinding the porous powder quartz and the inorganic pigment and then adding to the solvent and stirring;

[0035] (2) mixing and stirring alcohol-soluble organic silicon acrylic resin, nano silicon dioxide, nano calcium carbonate, fluorine-containing acrylic modified polyurethane resin and fluorine-con...

Embodiment 3

[0038] An antifouling exterior wall glaze, comprising the following components in parts by weight: 40 parts of alcohol-soluble silicone acrylic resin, 7 parts of nano silicon dioxide, 8 parts of nano calcium carbonate, 3 parts of fluorine-containing acrylic modified polyurethane resin, 3 parts of fluoroacrylic acid modified silicone resin, 32 parts of dibutyltin dilaurate, 0.8 parts of defoamer, 2 parts of dispersant, 45 parts of deionized water, 1.5 parts of inorganic pigment, 20 parts of porous powder quartz, 2 parts of leveling agent 1 part and accelerator 1 part.

[0039] A method for preparing an antifouling exterior wall glaze, comprising the following steps:

[0040] (1) Grinding the porous powder quartz and the inorganic pigment and then adding to the solvent and stirring;

[0041] (2) mixing and stirring alcohol-soluble organic silicon acrylic resin, nano silicon dioxide, nano calcium carbonate, fluorine-containing acrylic modified polyurethane resin and fluorine-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com