Vacuum phase change wastewater concentration and flue gas waste heat recovery system

A technology for waste water concentration and flue gas waste heat, which is applied in gaseous discharge waste water treatment, heat exchangers, indirect heat exchangers, etc., can solve the problems of high-quality heat energy consumption and high energy consumption, and achieve cascade utilization and improve heat exchange. effect, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

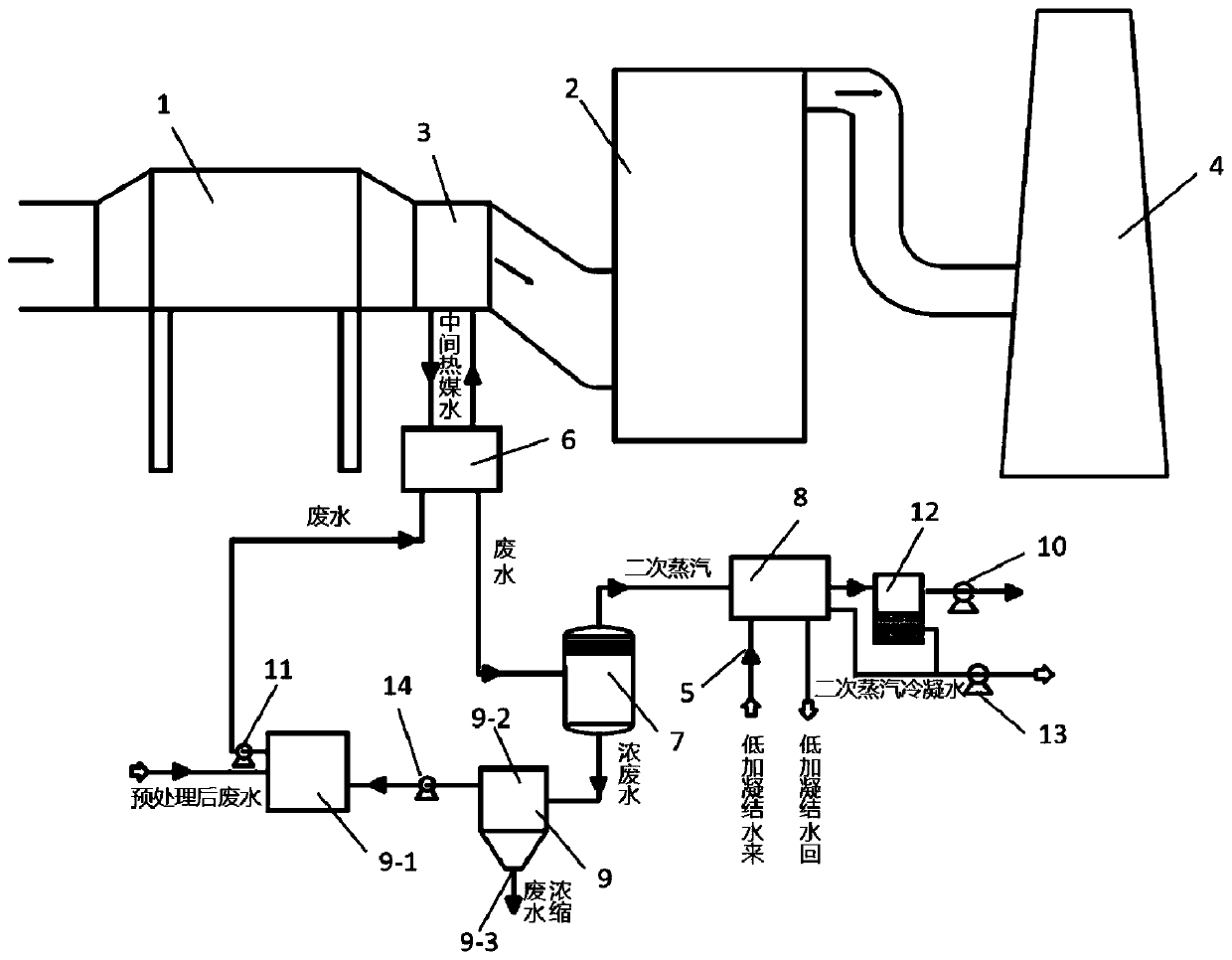

[0068] This embodiment provides a vacuum phase change wastewater concentration and flue gas waste heat recovery system, such as figure 1 As shown, it includes a dust removal unit 1 and a desulfurization unit 2 connected together, and also includes an economizer 3 and a wastewater concentration system. The economizer 3 is arranged between the dust removal unit 1 and the desulfurization unit 2, or is arranged along the direction of flue gas flow. Before dust removal unit 1; dust removal unit 1 is an electric dust collector, desulfurization unit 2 is a desulfurization tower, and economizer 3 is a low-temperature economizer. The setting of economizer 3 can improve the dust removal capacity of dust removal unit 1.

[0069] Such as figure 2 As shown, the waste water concentration system includes: a first heat exchanger 6, which communicates with the economizer 3, so that the waste water and the first heat exchange medium from the economizer 3 exchange heat in the first heat exchang...

Embodiment 2

[0094] Such as figure 1 As mentioned above, this embodiment provides a vacuum phase change wastewater concentration and flue gas waste heat recovery system, which includes a dust removal unit 1, a desulfurization unit 2, and a chimney 4 connected to each other, and also includes an economizer 3 and a wastewater concentration system, and the economizer 3 is set between the dust removal unit 1 and the desulfurization unit 2; the dust removal unit 1 is an electric precipitator, the desulfurization unit 2 is a desulfurization tower, and the economizer 3 is a low and low temperature economizer; the wastewater concentration system includes:

[0095] The first heat exchanger 6 communicates with the economizer 3, so that the waste water and the first heat exchange medium from the economizer 3 exchange heat in the first heat exchanger 6;

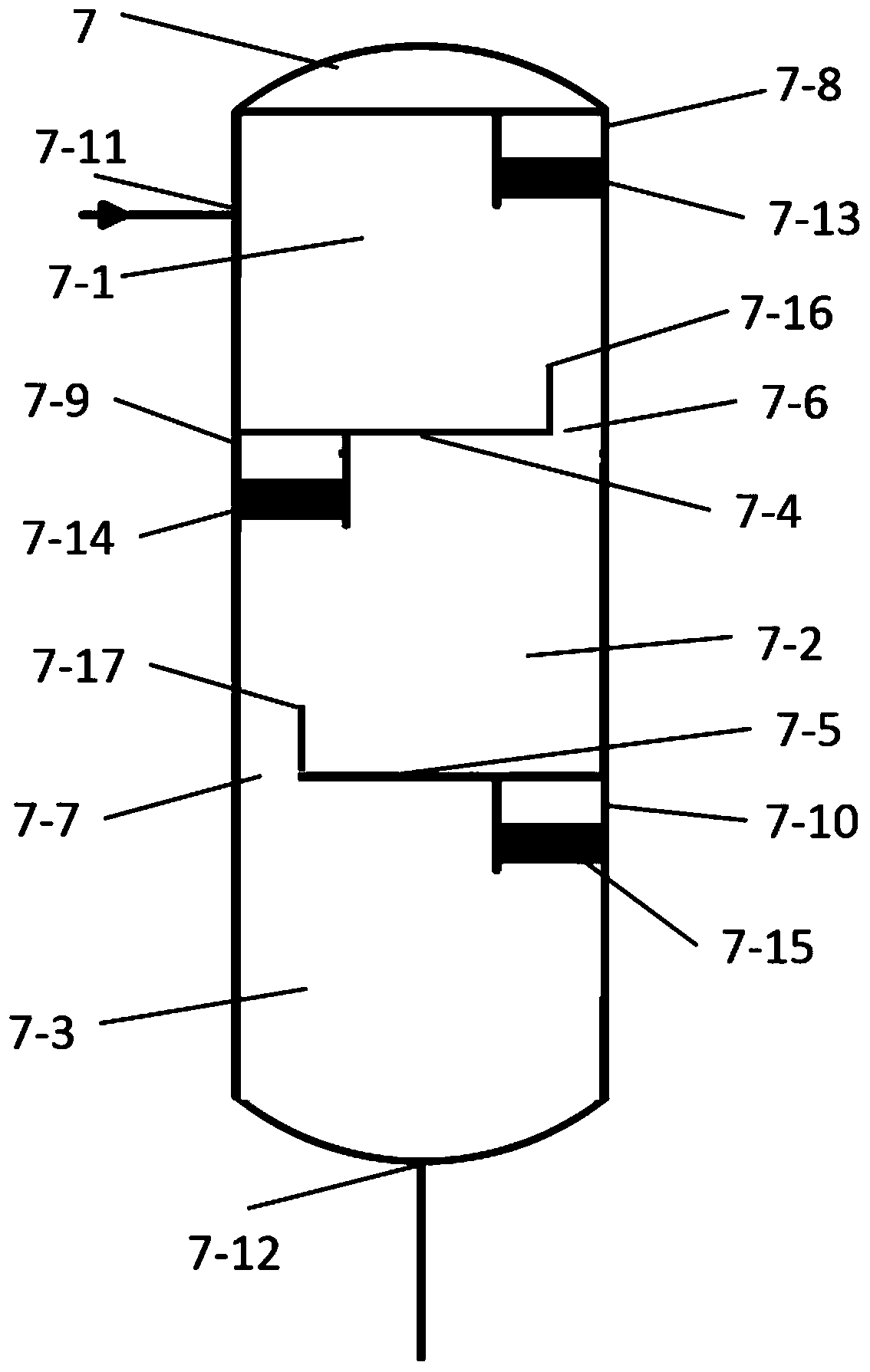

[0096] Flash tank 7, such as Figure 7 As shown, a first partition 7-4 and a second partition 7-5 are arranged inside, along the direction from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com