Production system for preparing thermoplastic prepreg through mud method

A production system and thermoplastic technology, which is applied in the field of production systems for preparing thermoplastic prepregs by slurry method, can solve the problems of poor impregnation effect, easy accumulation, affecting fiber damage and breakage, etc., and achieves easy monitoring, stable resin content, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with specific embodiment, further illustrate the present invention.

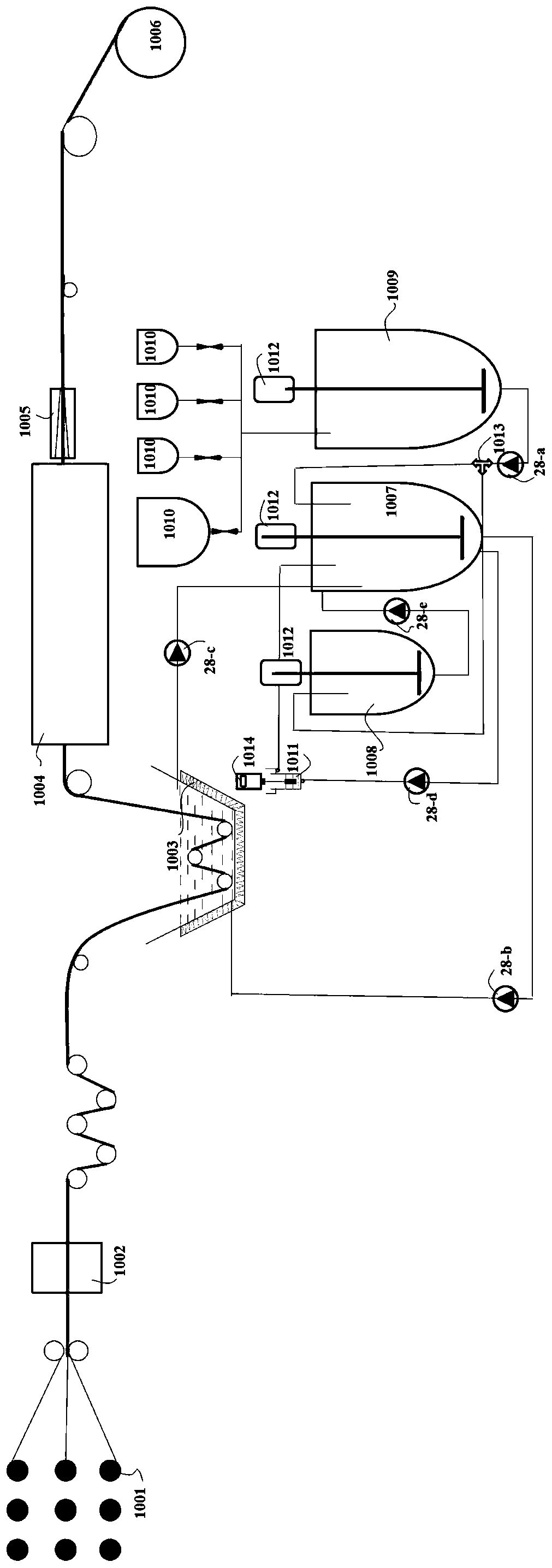

[0043] Such as figure 1 , The production system for preparing thermoplastic prepreg by slurry method of the present invention includes: creel 1001 arranged along the direction of fiber travel, sizing agent removal device 1002, dipping tank 1003, drying device 1004, pultrusion die 1005 and winding device 1006 The dipping tank is connected with a slurry concentration adjusting device, which includes a buffer tank 1007, a high-concentration slurry storage tank 1008, a slurry dispersion tank 1009, a raw material tank 1010, and a sample detection pool 1011. The fiber is wound on the creel, and the sizing agent removal device is used to remove the sizing agent of the fiber. The sizing agent removal device is a heating device, such as an infrared heating device, which can crack the sizing agent on the fiber at high temperature, so that the resin can be better attached to the surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com