Anti-corrosion high-temperature-resistant bag-type dust removal device

A bag filter and dust collector technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve problems such as increasing cleaning costs, damage to dust removal equipment, and equipment corrosion damage, reducing labor burden and improving The effect of the service life and the saving of cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

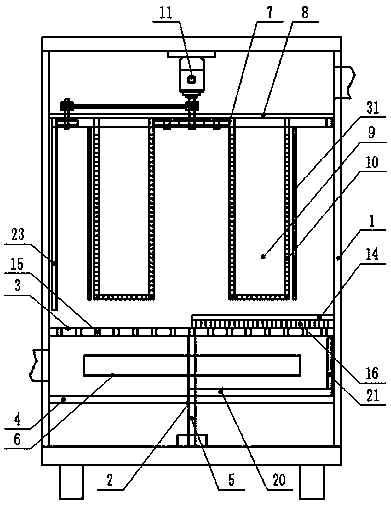

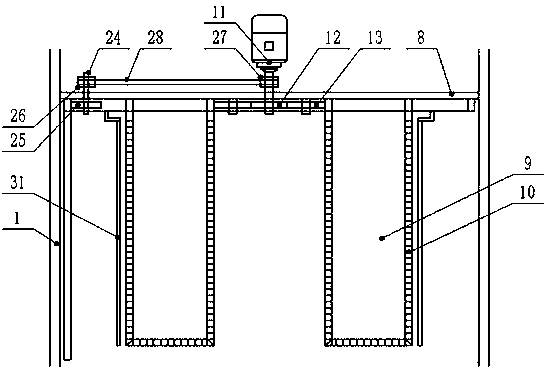

[0015] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 Now, an anti-corrosion and high-temperature-resistant bag filter provided by the present invention is described, including a dust collector body 1, the dust collector body 1 is a hollow cylinder, and the lower end of the dust collector body 1 is provided with an air guide filter mechanism 2. The air guide filter mechanism 2 includes an upper movable plate 3 provided at the lower end of the inner cavity of the dust collector body 1, a lower fixed plate 4 provided at the lower end of the inner cavity of the dust collector body 1, and a center of the lower fixed plate 4. The rotating shaft 5 and the guide vanes 6 evenly provided on the outside of the rotating shaft 5 are vertically movable through the upper part. The inner cavity of the dust collector body 1 is provided with a bag dust removal mechanism 7 above the position of the upper movable plate 3. The bag dust removal mechanism 7 includes a mounting fra...

Embodiment 2

[0016] Example 2: see figure 1Now, an anti-corrosion and high-temperature-resistant bag filter provided by the present invention is described. The outer bottom of the dust collector body 1 is evenly and vertically provided with support legs, and the upper movable plate 3 and the lower fixed plate 4 are round The lower fixed plate 4 is disc-shaped and the lower fixed plate 4 is located below the position of the upper movable plate 3, the inner side wall of the lower end of the dust collector body 1 is provided with an annular rolling groove, and the outer peripheral end wall of the upper movable plate 3 is provided with an annular roller , the outer circumferential end wall of the lower fixing plate 4 is fixedly connected with the inner end wall of the dust collector body 1, and the vertical bottom end of the rotating shaft 5 is flexibly connected with the inner bottom end wall of the dust collector body 1, The top end moves through the lower fixed plate 4 and is fixedly connec...

Embodiment 3

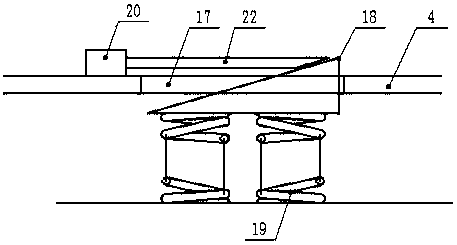

[0017] Embodiment 3: see figure 1 , image 3 ,, a kind of anti-corrosion high-temperature resistant bag filter provided by the present invention is described now, on the described lower fixing plate 4 and along its cross-sectional radial direction, there is a strip-shaped discharge port 17, and the strip-shaped discharge port The inner end of 17 is movable to be provided with dust retaining frame 18, and described dust retaining frame 18 is set as triangular prism shape, and described dust retaining frame 18 inclined end face is arranged upwards, and the lower end of described dust retaining frame 18 and the inner bottom of described dust remover body 1 Return springs 19 are evenly arranged between the end walls, and a first scraper 20 is arranged on the upper end of the lower fixing plate 4, and one end of the first scraper 20 in the longitudinal direction is fixedly connected with the rotating shaft 5, and the first scraper 20 is fixedly connected to the rotating shaft 5. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com