Brush tufting device

A brush and equipment technology, which is applied in the field of brush filling equipment, can solve the problems of large lubricated cam surface, oil scattering, high noise emission pollution, etc., and achieve the effects of small quality, reduced manufacturing cost, and improved running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

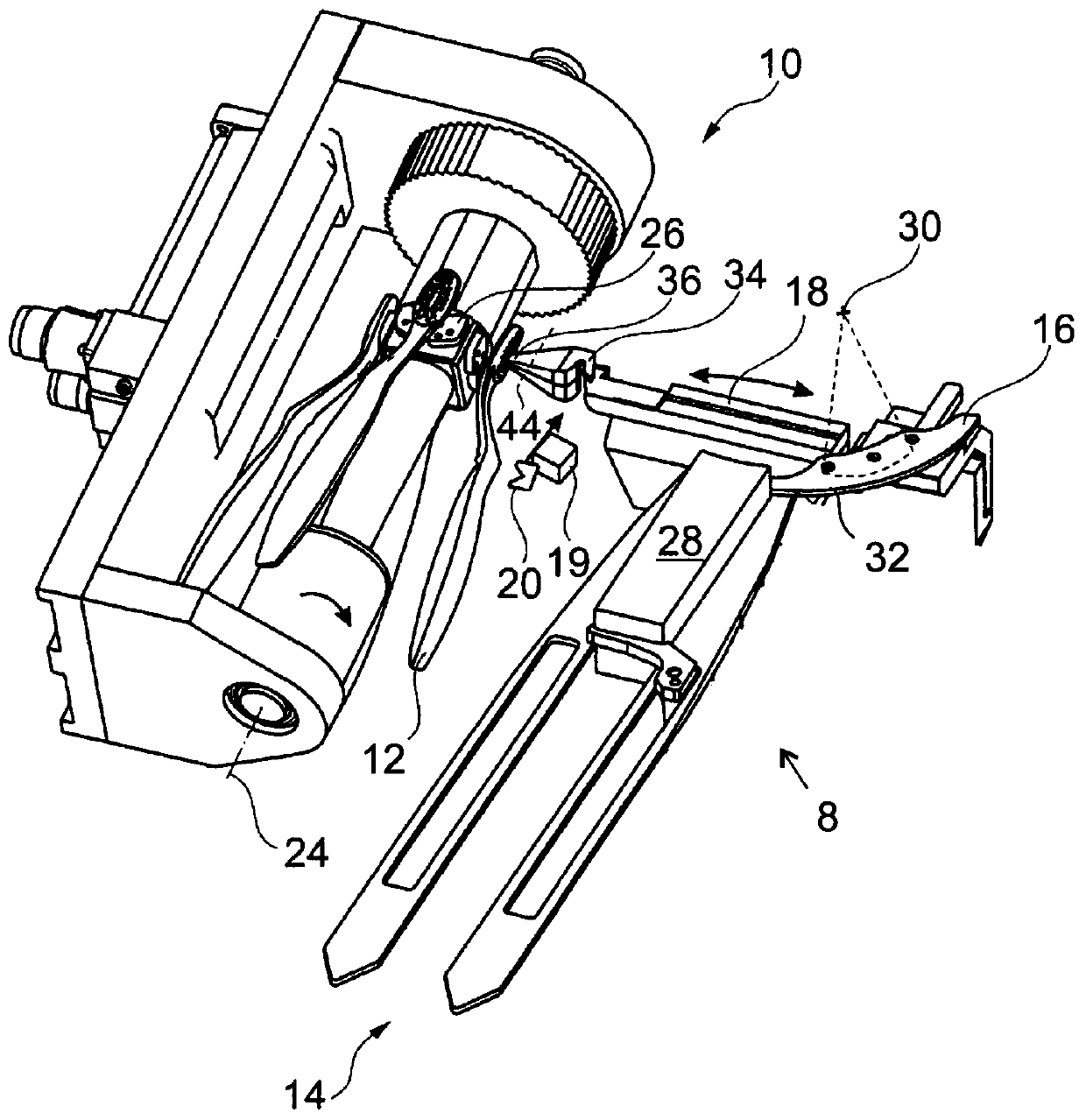

[0026] figure 1 A brush caulking device is shown having a caulking tool 8 comprising a plurality of sub-tools. The stuffing device comprises a reel 10 with a plurality of holders for the bristle carrier 12, a bristle magazine 14, a so-called beam taker (Bündelabnehmer) 16 as a sub-tool, and a tongue for stuffing as a further sub-tool Shaped piece 18. Furthermore, there is a conveying device 19 (likewise a subtool), symbolized by an arrow, for a so-called fastening element 20 , for example in the form of a wire loop or a thin metal sheet (also referred to as a blade).

[0027] In the bristle stuffing device, the bristle carrier 1, for example a small plate with openings or a form such as figure 1 The bristle carrier of the complete brush body shown is padded.

[0028] In the present example, the drum 10 is designed as a rotating holding tool, in which a plurality of bristle carriers 12 are accommodated on a support frame 26 rotatable about an axis 24, said bristle carriers b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com