Environment-friendly cable for safety fire protection

A fire-fighting and environmental protection technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of spontaneous combustion, the problem of spontaneous combustion of cables cannot be solved well, and the difficulty of rescue is aggravated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

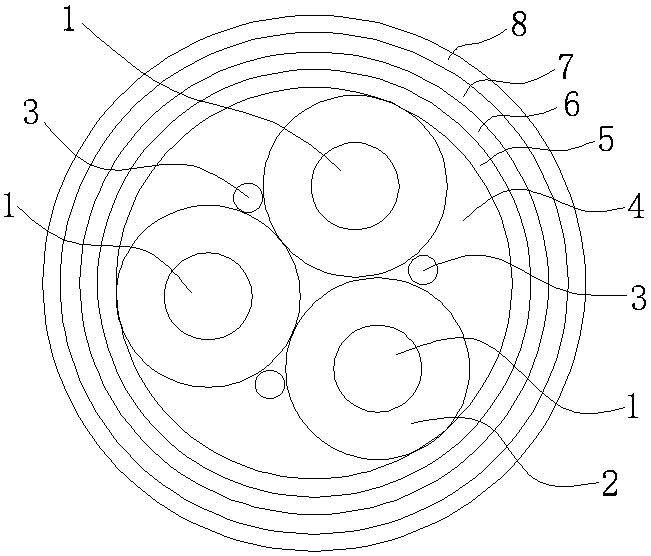

[0015] Such as figure 1 As shown, a kind of environment-friendly cable for safety and fire protection includes a plurality of conductors 1, the conductors 1 are extruded with insulating layers 2 to form insulated wire cores, and temperature sensing wires 3 are arranged at intervals between the insulated wire cores. A flame retardant filling layer 4 is arranged outside the wire core, and a wrapping layer 5 , a ceramicized silicon rubber layer 6 , an aluminum alloy tape armor 7 and a sheath 8 are arranged outside the flame retardant filling layer 4 in sequence.

[0016] During the operation of fire rescue, if the cable is in a complex and high-heat environment, such as when passing through a fire field, the cable may pass through a burning area, or when there is no open flame and a high-heat area, the cable may be locally heated when it contact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com