Aluminum template with high use efficiency and relatively material saving

A kind of aluminum formwork, high technology, applied in the direction of formwork/formwork components, joints of formwork/formwork/work frame, construction components on site, etc., can solve aluminum formwork shaking, increase material cost, increase Time cost and other issues, to achieve the effect of simple installation and disassembly, stable and fast connection, saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

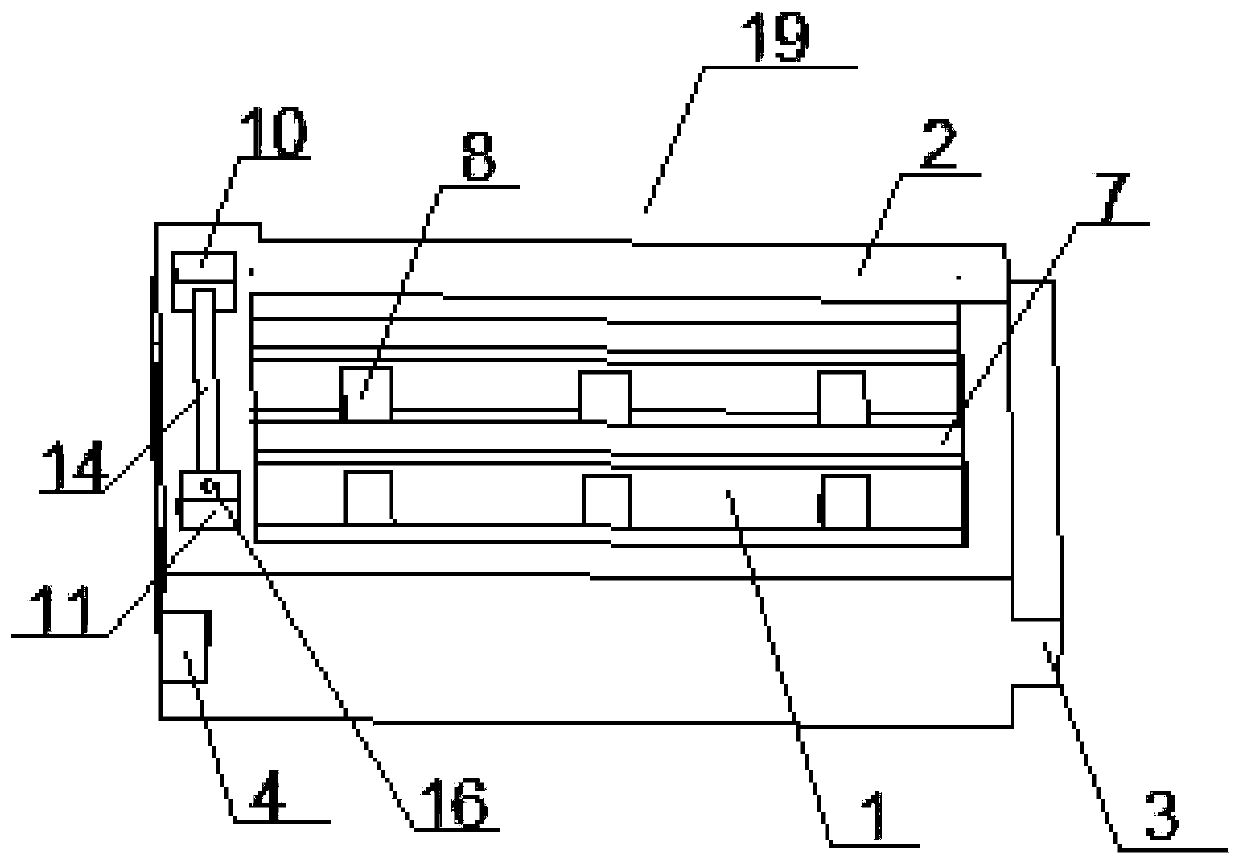

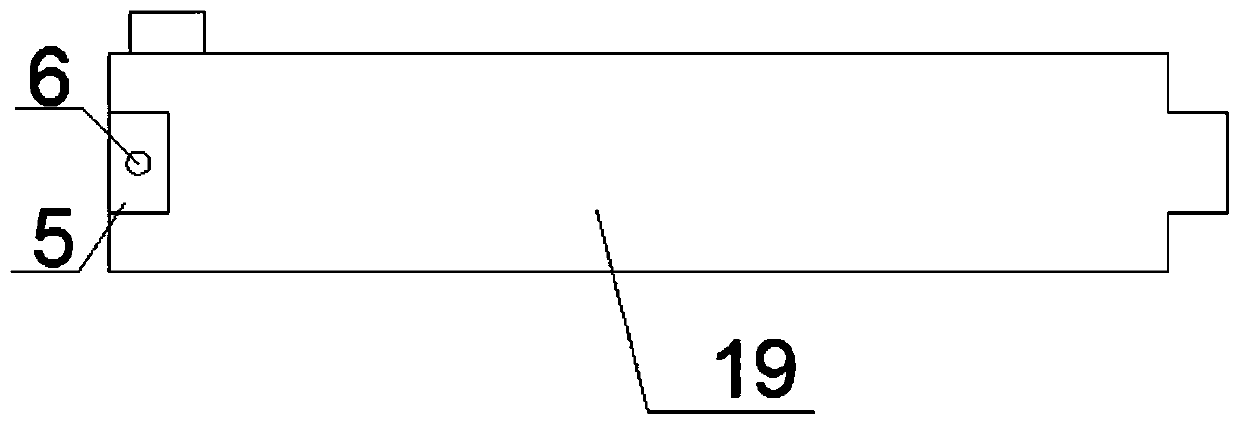

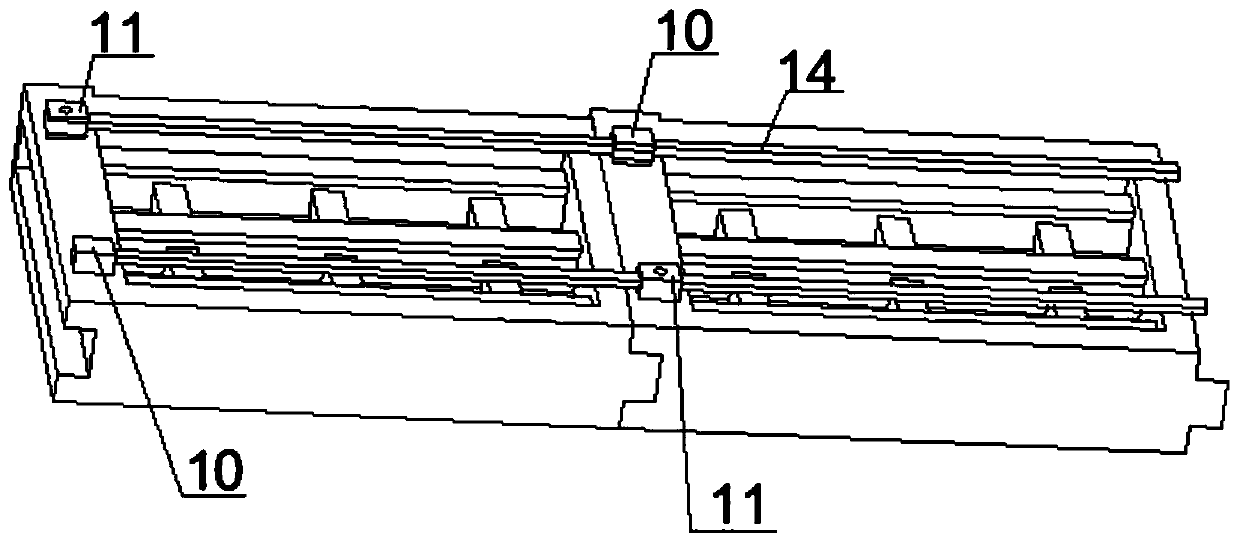

[0027] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0028] In the prior art, the connection of two aluminum formworks is fixed by multiple bolts. At the same time, the bolts and the aluminum formwork are interference fit, which requires the use of a fixed hammer, which makes installation and disassembly very difficult and increases the time for installation and disassembly. The time cost is increased, and at the same time, it is easy to cause damage to the aluminum formwork during the installation and disassembly process, which reduces the service life of the aluminum formwork. Therefore, it is necessary to abandon the traditional bolt connection and design a new connection method. This application sets the following structure :

[0029] Such as Figure 1 to Figure 4 As shown, an aluminum f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com