Inner sleeve arc-shaped hole forming and sunk pipeline lifting and restoring method

A technology of inner casing and pipeline, which is applied in the direction of drilling equipment and methods, casing, pipeline support, etc., can solve problems such as poisoning, difficult construction conditions, modification of disease conditions and restrictions, and achieve clear goal orientation and thorough treatment effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

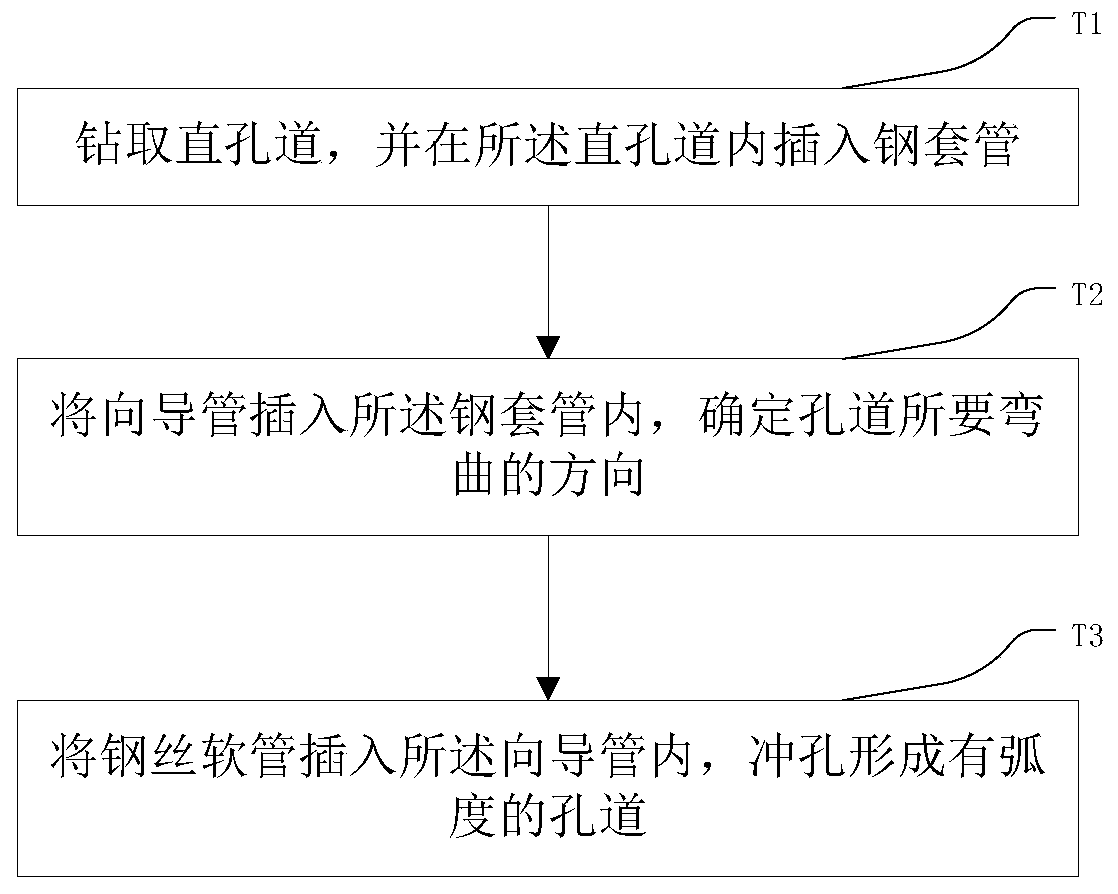

[0041] Please also refer to Figure 1a , Figure 3-Figure 5 , the application provides a method for forming a hole in an arc of an inner casing, comprising the steps of:

[0042] T1, drilling a straight tunnel, and inserting a steel casing 3 into the straight tunnel;

[0043] T2. Insert the guide tube 4 into the steel casing 3, and determine the direction in which the tunnel will be bent;

[0044] T3. Insert the steel wire hose 5 into the guide tube 4, and punch holes to form a curved channel.

[0045] As a preferred solution, in this embodiment, the guide tube is a rubber tube with a certain curvature at the end.

[0046] Specifically, the function of the guide tube 4 is to guide the punching, so as to facilitate punching to the designated position, that is, the bottom of the subsidence pipe section 1, so the end of the guide tube 4 must have a certain curvature, and The orientation can be determined; in addition, the steel sleeve 3 is straight, so the material of the guid...

Embodiment 2

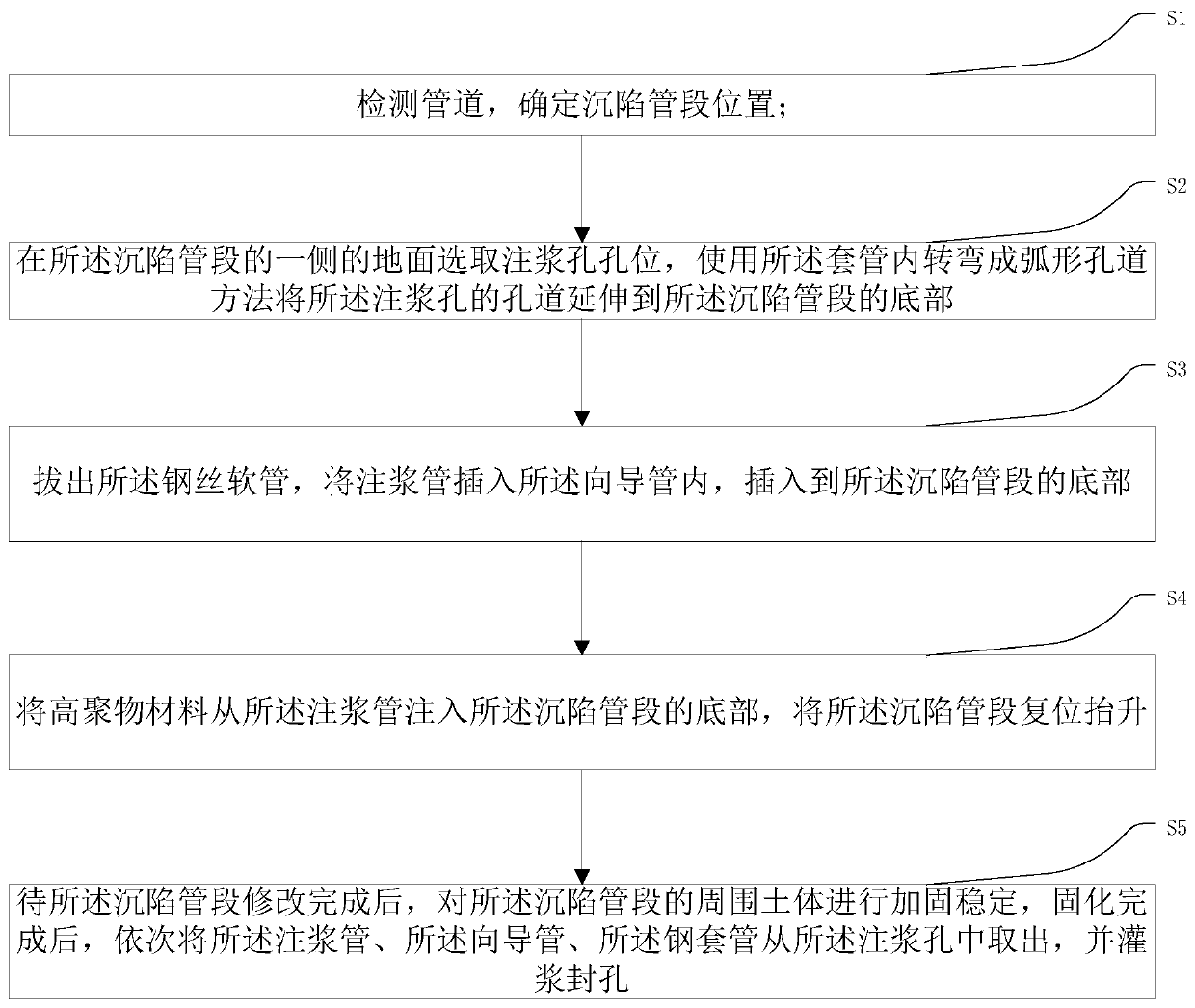

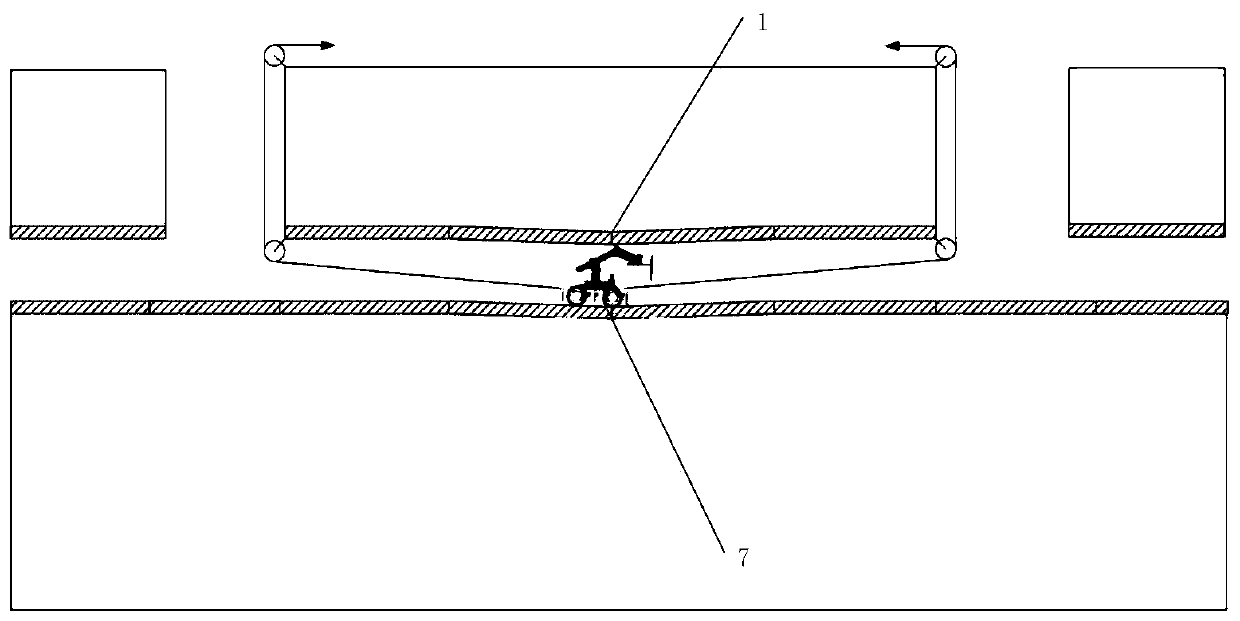

[0051] Please also refer to Figure 1- Figure 7 , the present invention provides a method for resetting and lifting pipeline subsidence, comprising the steps of:

[0052] S1. Detect the pipeline and determine the position of the subsidence pipe section 1;

[0053] S2. Select the hole position of the grouting hole 2 on the ground on one side of the subsidence pipe section 1, and extend the channel of the grouting hole 2 to the bottom of the subsidence pipe section 1 by using the inner casing arc forming hole method;

[0054]S3. Pull out the steel wire hose 5, insert the grouting pipe into the guide pipe 4, and insert it into the bottom of the subsidence pipe section 1;

[0055] S4. Inject the high polymer material from the grouting pipe 6 into the bottom of the subsidence pipe section 1, and reset and lift the subsidence pipe section 1.

[0056] Specifically, firstly, the specific position of the subsidence pipe section 1 must be detected, and after the position of the subsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com