Whirling well outer wall template construction method

A construction method and swirling well technology, which can be used in excavation, artificial islands, water conservancy projects, etc., can solve the problems of consuming labor, formwork, scaffolding and time, increasing the amount of earthwork excavation, and many construction procedures, so as to reduce earthwork excavation The effect of reducing the amount of excavation, shortening the construction period, and avoiding earthwork backfilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

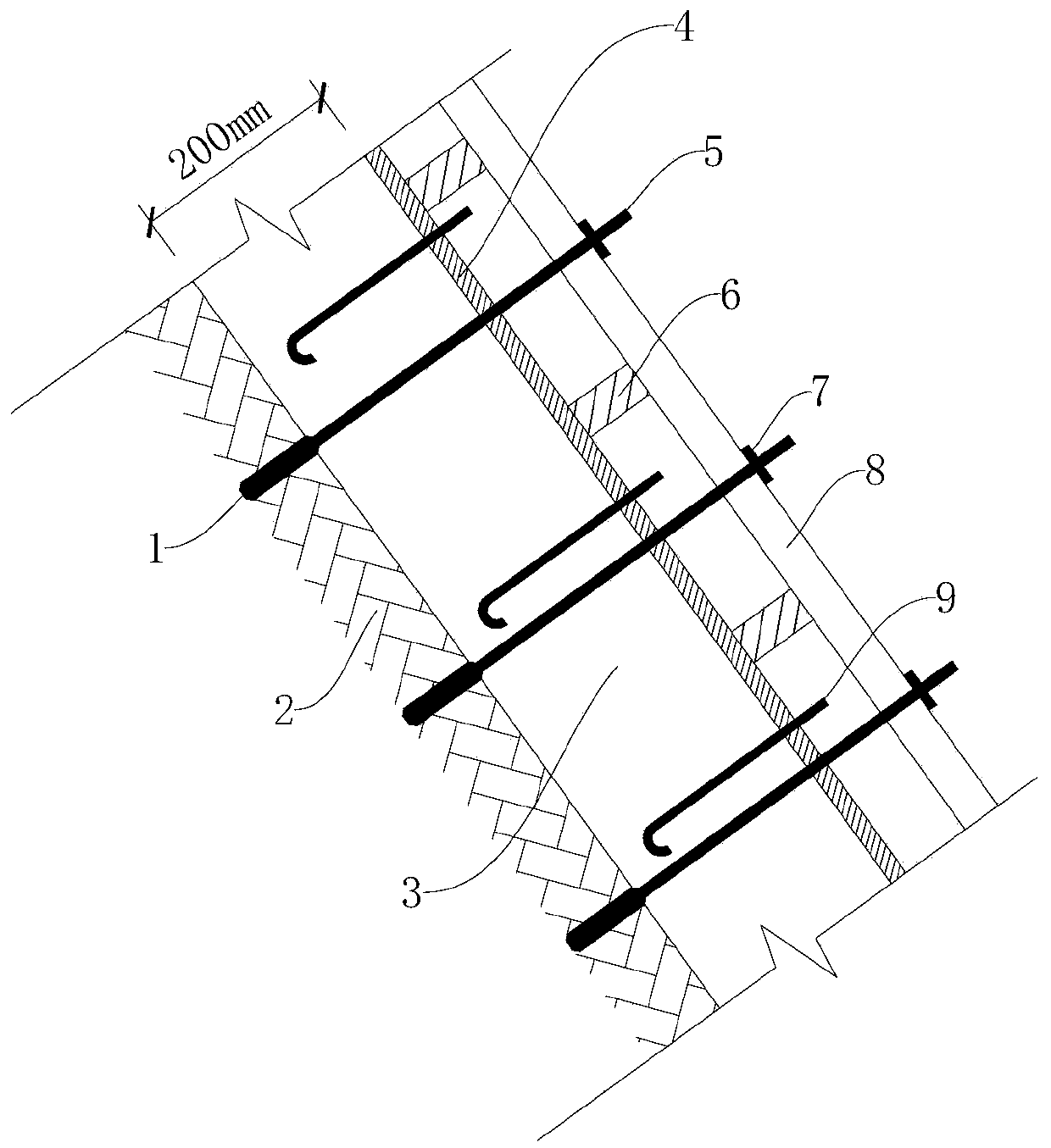

[0035] Such as figure 1 and figure 2 Shown, a kind of swirling well outer wall formwork construction method comprises:

[0036] Earthwork excavation steps: during the earthwork excavation construction of the swirl well, dig xmm more outward along the well wall 10;

[0037] Drilling and installation steps: use a drill to drill holes on the rock base at the 3 positions of the retaining wall, the drilling distance is ymm*ymm, and the drilling depth is ≥100mm. After cleaning the hole, install the expansion bolt 1 in the hole;

[0038] Reinforcement installation steps: bind reinforcement mesh on the base of retaining wall 3;

[0039] Installation steps of the first formwork: the first formwork (retaining wall 3 formwork) is reinforced with the first pair of water-stop screw rods 5 (double bolts). 1 The welding is firm, and the expansion bolt 1 is passed through the first formwork (wooden formwork), and the installation and reinforcement of the first formwork are carried out;

...

Embodiment 2

[0048] In this embodiment, specific structural details are optimized, making the entire construction method easier to implement.

[0049] Such as figure 1 As shown, the construction structure of the retaining wall 3 at the inclined well wall 10 of the swirling well includes the first formwork, the first pair of water-stop screw rods 5, the first pad, the first reinforcement rod and the expansion bolts fixed in the bedrock 2 1;

[0050] The first pair of water-stop screws 5 are welded with expansion bolts 1 and pass through the first template; the first pad is arranged outside the first template, and the first reinforcement rod is installed on the first pad; the first pair of water-stop screws 5 The ends are fixed by fasteners; the embedded parts are fixed on the first template.

[0051] The retaining wall 3 at the inclined well wall 10 of the swirling well is designed as a 200mm thick reinforced concrete structure, that is, the distance between the first template and the fou...

Embodiment 3

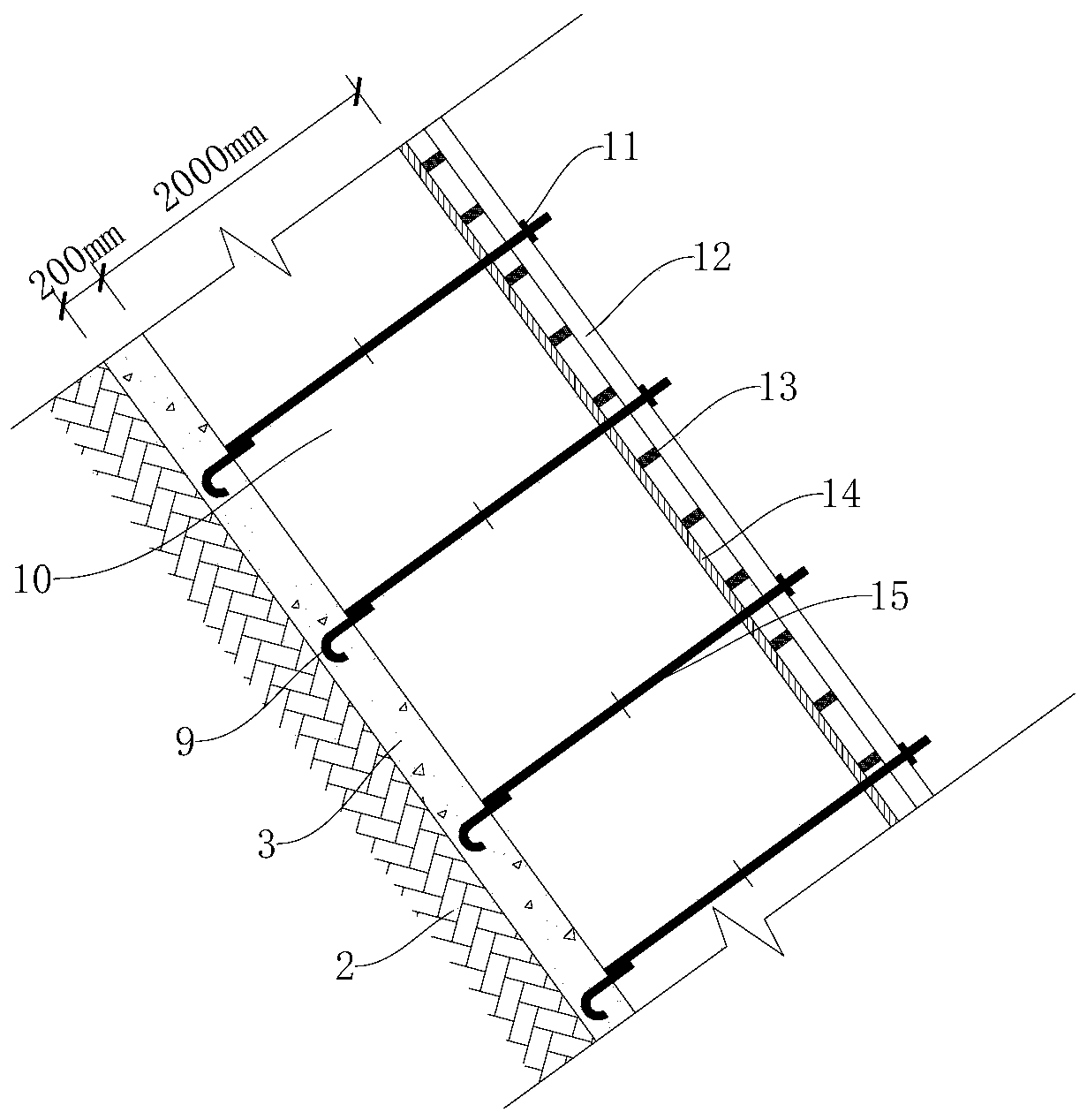

[0055] Such as figure 2 As shown, the present invention optimizes the formwork construction structure of the well wall 10, and the formwork construction structure of the well wall 10 includes a second formwork, a second pair of pulling water-stop screws 15, a second cushion block, and a second reinforcement rod;

[0056] The second pair of pull water-stop screw rods 15 are welded with the embedded parts embedded in the retaining wall 3 and pass through the second template; the second template is provided with a second cushion block, and the second reinforcement rod is installed on the second cushion block; the second The ends of the water stop screw 15 are fastened by a fixing piece.

[0057] After the reinforced concrete retaining wall 3 is poured, remove the retaining wall 3 wooden formwork (the second formwork) and carry out the swirling well wall 10 steel bar binding, and simultaneously pull the well wall 10 pairs of water-stop screws (the second pair of water-stop screws...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Exposed length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com