Low-density petroleum fracturing propping agent and preparation method thereof

A fracturing proppant and low-density technology, which is applied in chemical instruments and methods, earthwork drilling, production fluids, etc., can solve the problems of waste of resources and low performance of oil fracturing proppant, and achieve the goal of improving the opening gap and low cost , good spherical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

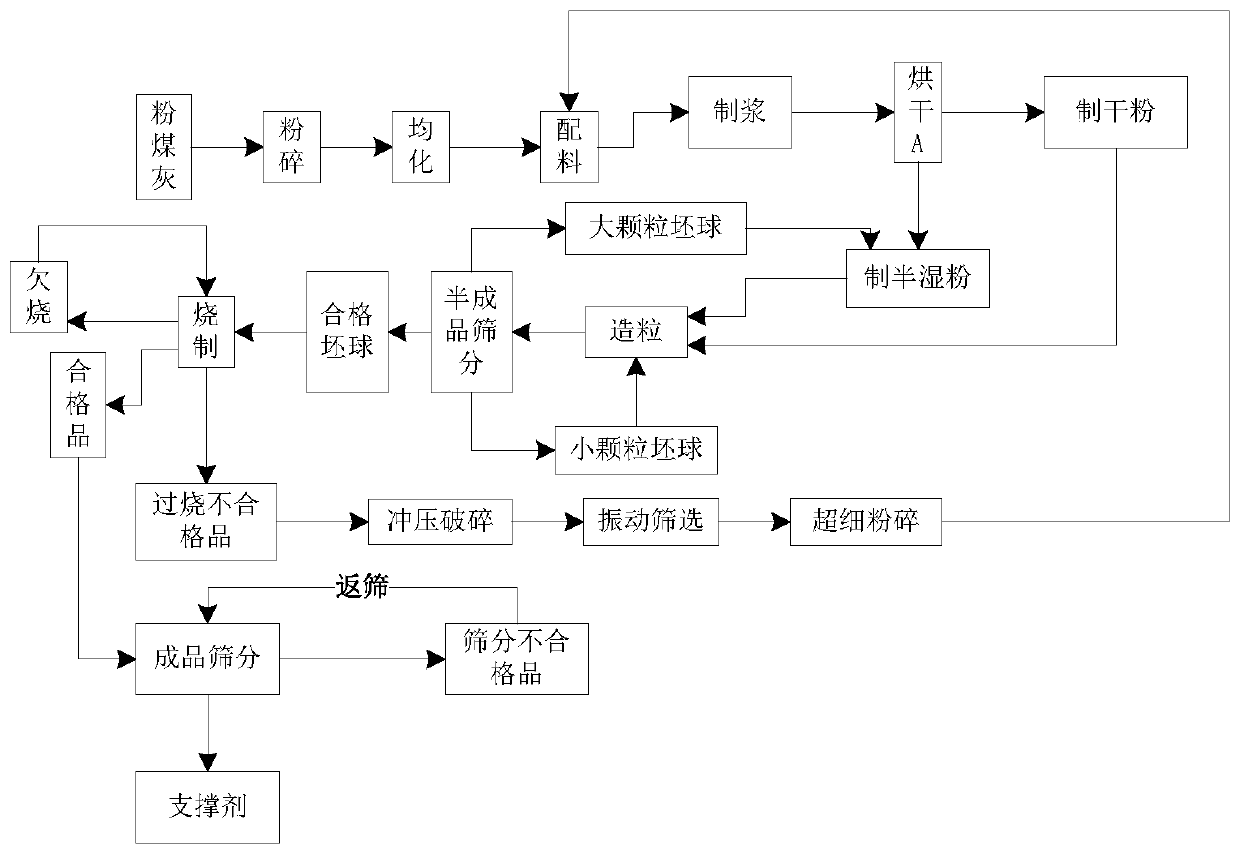

Image

Examples

Embodiment 1

[0044] The low-density petroleum fracturing proppant of this embodiment is prepared from the following components:

[0045] 4% to 6% lightly burned bauxite, 6% to 8% bentonite, 0.8% to 1.2% manganese powder, 0.8% to 1.2% lightly burned magnesium powder, 0.4% to 0.6% silica fume, 0 % to 0.5% of the overburned recycled powder and the balance is low-aluminum fly ash.

[0046] Wherein, in the light-burned bauxite, Al 2 o 3 The mass percent composition of 70%; In the described bentonite, the mass percent composition of montmorillonite is 85%; In the described low aluminum fly ash, Al 2 o 3 The mass percentage content is 36.52%, SiO 2 The mass percentage content is 38.56%, Fe 2 o 3 The mass percentage of CaO is 4.05%, and the mass percentage of CaO is 10.35%; the light-burned bauxite, the bentonite, the manganese powder, the light-burned magnesium powder, the low-alumina fly ash And the silica fume has passed through a 200-mesh sieve, with a passing rate of 99%.

[0047] Suc...

Embodiment 2

[0059] The low-density petroleum fracturing proppant of this embodiment is prepared from the following components:

[0060] 4% to 6% lightly burned bauxite, 6% to 8% bentonite, 0.8% to 1.2% manganese powder, 0.8% to 1.2% lightly burned magnesium powder, 0.4% to 0.6% silica fume, 0 % to 0.5% of the overburned recycled powder and the balance is low-aluminum fly ash.

[0061] Wherein, in the light-burned bauxite, Al 2 o 3 The mass percent composition of 70%; In the described bentonite, the mass percent composition of montmorillonite is 85%; In the described low aluminum fly ash, Al 2 o 3 The mass percentage content is 36.52%, SiO 2 The mass percentage content is 38.56%, Fe 2 o 3 The mass percentage of CaO is 4.05%, and the mass percentage of CaO is 10.35%; the light-burned bauxite, the bentonite, the manganese powder, the light-burned magnesium powder, the low-aluminum fly ash And the silica fume has passed through a 200-mesh sieve, with a passing rate of 99%.

[0062] Su...

Embodiment 3

[0074] The low-density petroleum fracturing proppant of this embodiment is prepared from the following components:

[0075] 4% to 6% lightly burned bauxite, 6% to 8% bentonite, 0.8% to 1.2% manganese powder, 0.8% to 1.2% lightly burned magnesium powder, 0.4% to 0.6% silica fume, 0 % to 0.5% of the overburned recycled powder and the balance is low-aluminum fly ash.

[0076] Wherein, in the light-burned bauxite, Al 2 o 3 The mass percent composition of 70%; In the described bentonite, the mass percent composition of montmorillonite is 85%; In the described low aluminum fly ash, Al 2 o 3 The mass percentage content is 36.52%, SiO 2 The mass percentage content is 38.56%, Fe 2 o 3 The mass percentage of CaO is 4.05%, and the mass percentage of CaO is 10.35%; the light-burned bauxite, the bentonite, the manganese powder, the light-burned magnesium powder, the low-aluminum fly ash And the silica fume has passed through a 200-mesh sieve, with a passing rate of 99%.

[0077] Su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| crush indicators | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com