Preparation method of horizontal well plugging agent

A technology for horizontal wells and plugging agents, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor temperature and salt resistance, short validity period, etc., and achieve poor permeability, long validity period, good water resistance and The effect of oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] A preparation method of horizontal well plugging agent, comprising the following steps:

[0051] A. Take 200g of montmorillonite, place it in 800mL of dilute hydrochloric acid with a mass fraction of 7.5%, stir and make slurry for 12h, after suction filtration and distillation of hydrochloric acid, wash repeatedly with distilled water until the pH is 7.0, put the treated montmorillonite in Dry at 100°C for two days and reserve;

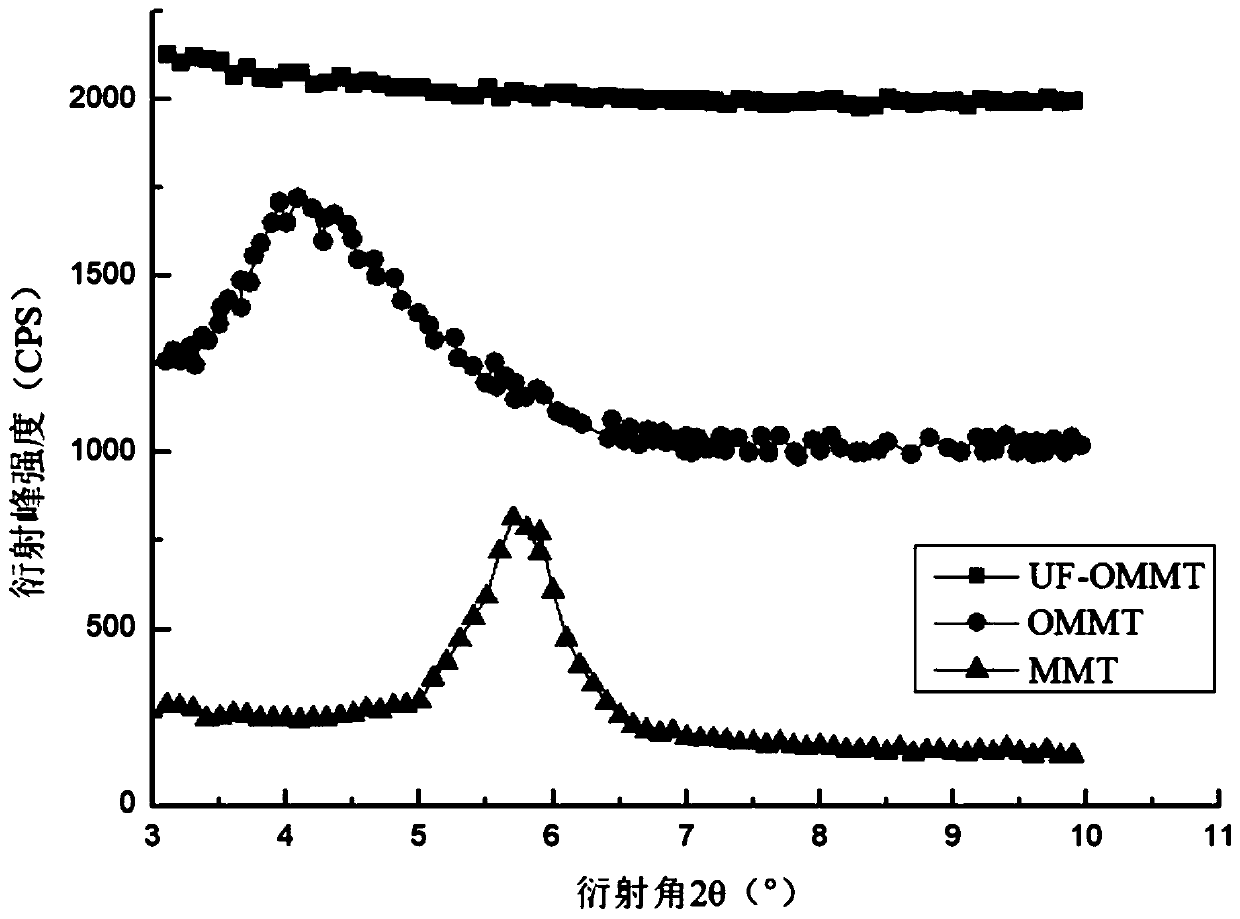

[0052] B. Take 20g of dried montmorillonite in step A, uniformly disperse it in 400mL of deionized water at a stirring speed of 300 rpm, age for 24h, heat up to 65°C, add 6.56g of hexadecyltrimethyl bromide Ammonium chloride, stirred at a high speed of 300rpm for 1.5h; cooled to 25°C, filtered under reduced pressure, washed with pure water, until silver nitrate was added to the filtrate without precipitation, dried in vacuum at 80°C for 12h, ground, crushed and sieved , the sieve mesh number is 325 orders, makes modified montmorillonite (O-MMT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com