Polishing solution for barium fluoride crystals

A technology of polishing liquid and barium fluoride, which is applied in the field of polishing liquid, can solve problems such as poor polishing effect, loss of polishing ability, and high specificity of polishing powder, so as to avoid poor polishing effect, increase suspension effect, and stabilize suspension performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

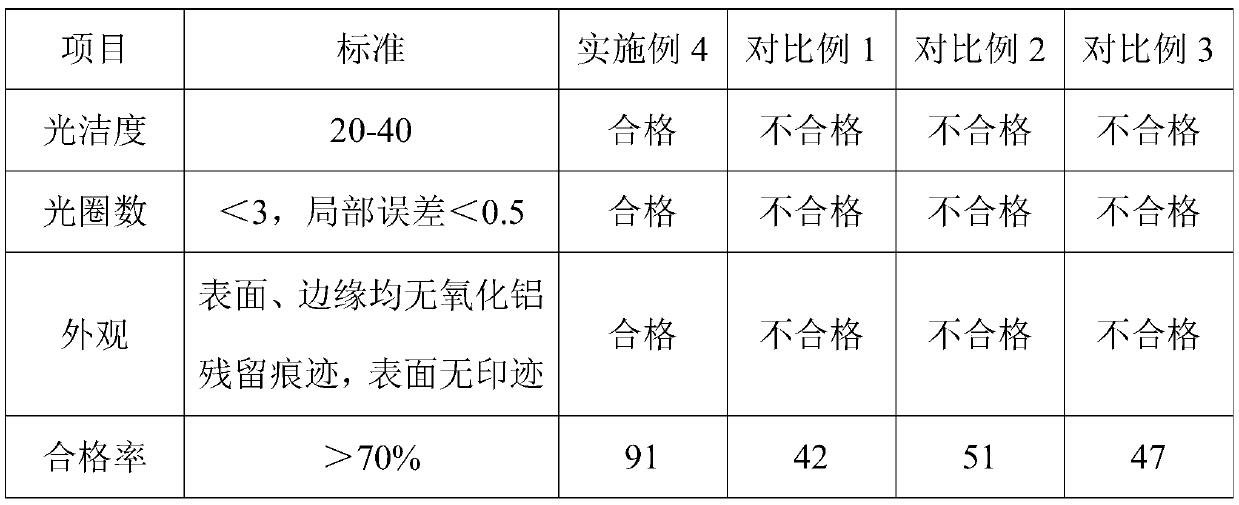

Examples

Embodiment 1

[0016] A polishing solution for barium fluoride crystals, the raw materials of which include by weight: 140 parts of aluminum oxide, 35 parts of suspending agent, and 8000 parts of water; wherein, the suspending agent is glycerol and talcum powder.

Embodiment 2

[0018] A polishing solution for barium fluoride crystals, the raw materials of which include by weight: 160 parts of aluminum oxide, 25 parts of suspending agent, and 15,000 parts of water; wherein, the suspending agent is glycerol and talcum powder;

[0019] Wherein, the weight ratio of glycerol and talcum powder is 4:1;

[0020] The particle size of alumina is ≤0.5μm;

[0021] The density of the polishing liquid for barium fluoride crystal is 1.017g / cm 3 .

Embodiment 3

[0023] A polishing solution for barium fluoride crystals, its raw materials include by weight: 145 parts of aluminum oxide, 32 parts of suspending agent, and 13000 parts of water; wherein, the suspending agent is glycerol and talcum powder;

[0024] Wherein, the weight ratio of glycerol and talcum powder is 6:1;

[0025] The particle size of alumina is ≤0.5μm;

[0026] The density of the polishing liquid for barium fluoride crystal is 1.013g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com