Meat and bone meal organic fertilizer and preparation technology thereof

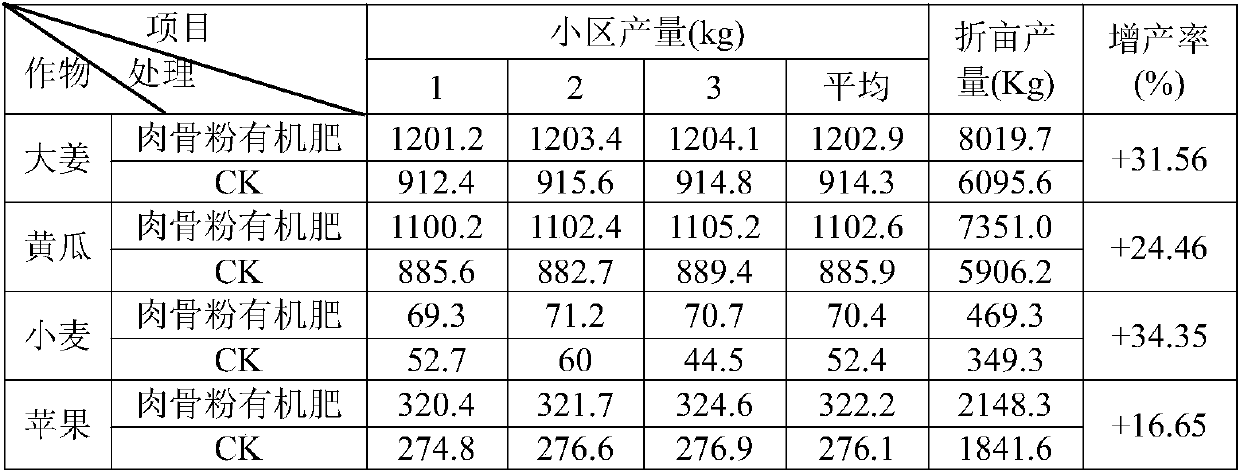

A technology of meat and bone meal and organic fertilizer, applied in the preparation of organic fertilizer, organic fertilizer, biological organic part treatment, etc., can solve the problem that the fertilizer effect of meat and bone meal cannot be fully released and utilized, plant nutrition is not scientifically compounded, and fertilizer damage, etc. To achieve the effect of improving crop resistance and resistance to diseases and insect pests, improving crop yield and product quality, and improving the rational utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 100kg of rapeseed cake and 130kg of sesame cake and pulverize, then mix evenly with 450kg of meat and bone meal, 50kg of soybean meal, 268.5kg of soot residue, 1kg of compound fermentation bacteria and 0.5kg of compound enzyme, add 25kg of lightly burned magnesium during the mixing process, and simultaneously Control the moisture content of the material to 50% by spraying tap water, load the mixed material into the fermentation tank, stack it into a strip-shaped material pile with a height of 1 meter and a width of 4 meters for fermentation, and pass through the material pile every 12 hours during the fermentation process. Into the air for 10 minutes, control the temperature of the stockpile, when the material temperature reaches 50 ℃, use the turning machine to turn the material, when the temperature of the stockpile does not rise after the last turning, that is, the rotting is complete; the rotted material is loaded Put it into the hardened drying shed for natura...

Embodiment 2

[0031] Weigh 120kg of rapeseed cake and 150kg of sesame cake and pulverize, then mix evenly with 420kg of meat and bone meal, 75kg of soybean meal, 232.7kg of soot residue, 1.5kg of compound fermentation bacteria and 0.8kg of compound enzyme, and add 30kg of lightly burned magnesium during the mixing process. At the same time, by spraying tap water to control the moisture content of the material to 52%, the mixed material is loaded into the fermentation tank, and stacked into a strip-shaped material pile with a height of 1 meter and a width of 4 meters for fermentation. Ventilate the air for 10 minutes to control the temperature of the stockpile. When the temperature of the material reaches 51°C, use a turning machine to turn the material. When the temperature of the stockpile does not rise after the last turning, it means that the material is completely decomposed; the material after decomposing Load it into the hardened drying shed for natural drying. During the period, the m...

Embodiment 3

[0035] Weigh 150kg of rapeseed cake and 130kg of sesame cake and pulverize, then mix evenly with 455kg of meat and bone meal, 60kg of soybean meal, 202.2kg of soot residue, 1.8kg of compound fermentation bacteria and 1kg of compound enzyme, add 35kg of lightly burned magnesium during the mixing process, and simultaneously Control the moisture content of the material to 55% by spraying tap water, load the mixed material into the fermentation tank, stack it into a strip-shaped material pile with a height of 1 meter and a width of 4 meters for fermentation, and pass through the material pile every 12 hours during the fermentation process. Into the air for 10 minutes to control the temperature of the stockpile. When the material temperature reaches 52°C, use a turning machine to turn the material. When the temperature of the stockpile does not rise after the last turning, it means that it is completely decomposed; Put it into the hardened drying shed for natural drying, during whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com