Ceramic brick with matt glaze surface and preparation method of ceramic brick

A matte glaze, ceramic tile technology, applied in the field of architectural ceramics, can solve the problems of the large influence on the pattern color development of the green body fabric layer, the poor combination of the matte glaze and the green body, and the unnatural and delicate pattern performance. Compatibility and bonding strength, improve decorative effect and practical experience, ensure the effect of permeability and stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

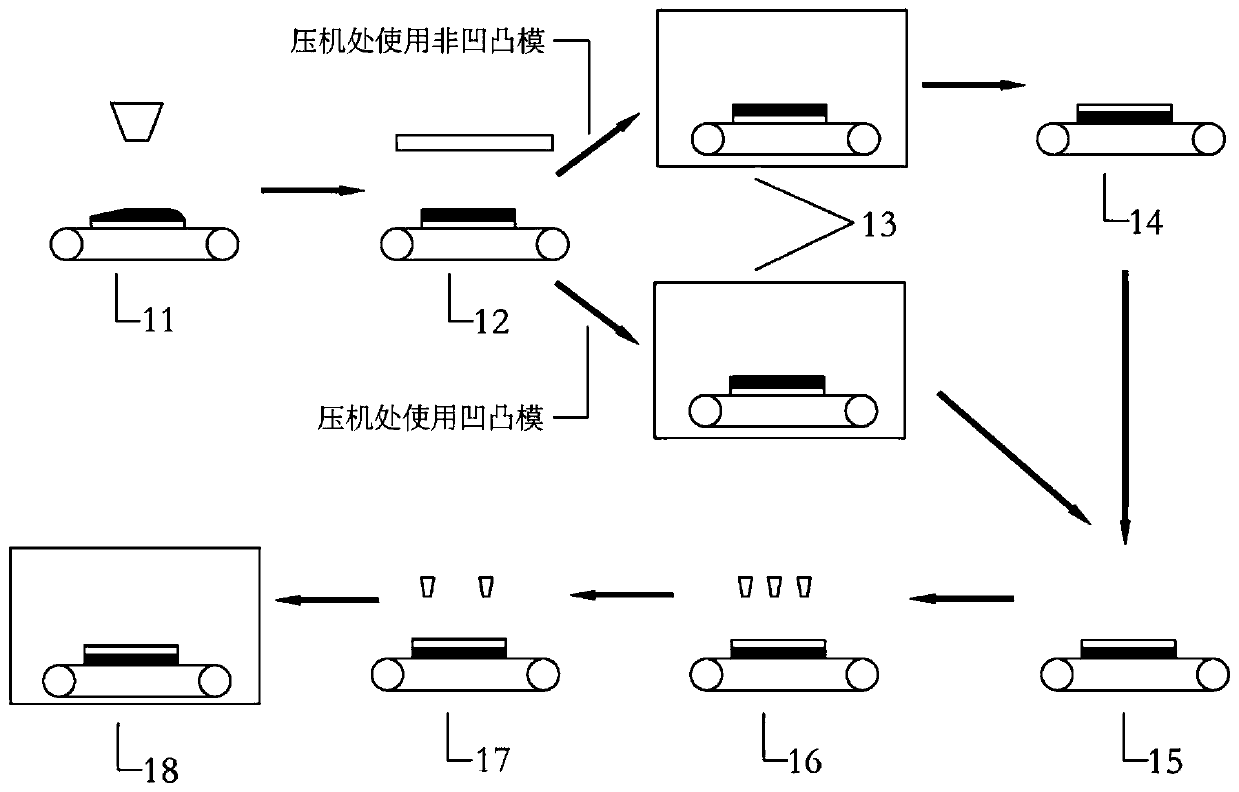

[0037] Such as figure 1 Shown, a kind of preparation method with the ceramic tile of dull glaze, comprises the steps:

[0038] (1) Micro-powder secondary distribution 11: Prepare powder according to the raw material formula of the green body, and perform ball milling, slurry homogenization, spray granulation, and stale silo according to the preparation process of ordinary ceramic tiles, and use the distribution device to distribute the bottom material layer and fabric layer.

[0039] The chemical composition of the primer is: silicon dioxide 75wt%, aluminum oxide 15wt%, potassium oxide 3wt%, sodium oxide 1.5wt%, calcium oxide 1wt%, magnesium oxide 1wt%, iron oxide 2.5wt%, titanium oxide 1wt% %; the chemical composition of the fabric is: silicon dioxide 70wt%, aluminum oxide 18wt%, potassium oxide 5wt%, sodium oxide 2.5wt%, calcium oxide 1.3wt%, magnesium oxide 1.5wt%, iron oxide 0.2wt%, Titanium oxide 1.5wt%.

[0040] (2) Dry press molding 12: use a non-concave-convex mold ...

Embodiment 2

[0053] Such as figure 1 Shown, a kind of preparation method with the ceramic tile of dull glaze, comprises the steps:

[0054] (1) Micro-powder secondary distribution 11: Prepare powder according to the raw material formula of the green body, and perform ball milling, slurry homogenization, spray granulation, and stale silo according to the preparation process of ordinary ceramic tiles, and use the distribution device to distribute the bottom material layer and fabric layer.

[0055] The chemical composition of the primer is: 70wt% of silicon dioxide, 20wt% of aluminum oxide, 3wt% of potassium oxide, 1.5wt% of sodium oxide, 1.5wt% of calcium oxide, 1.5wt% of magnesium oxide, 1.5wt% of iron oxide, Titanium 1wt%; the chemical composition of the fabric is: silicon dioxide 70wt%, aluminum oxide 20wt%, potassium oxide 3wt%, sodium oxide 2.9wt%, calcium oxide 1.2wt%, magnesium oxide 1.2wt%, iron oxide 0.2wt% %, titanium oxide 1.5wt%.

[0056] (2) Dry press molding 12: use a non-c...

Embodiment 3

[0069] Such as figure 1 Shown, a kind of preparation method with the ceramic tile of dull glaze, comprises the steps:

[0070] (1) Micro-powder secondary distribution 11: Prepare powder according to the raw material formula of the green body, and perform ball milling, slurry homogenization, spray granulation, and stale silo according to the preparation process of ordinary ceramic tiles, and use the distribution device to distribute the bottom material layer and fabric layer.

[0071] The chemical composition of the primer is: silicon dioxide 72wt%, aluminum oxide 18wt%, potassium oxide 2.5wt%, sodium oxide 1.5wt%, calcium oxide 2wt%, magnesium oxide 1.5wt%, iron oxide 1.5wt%, oxide Titanium 1wt%; the chemical composition of the fabric is: silicon dioxide 71wt%, aluminum oxide 20wt%, potassium oxide 2wt%, sodium oxide 2.9wt%, calcium oxide 1.2wt%, magnesium oxide 1.2wt%, iron oxide 0.2wt% %, titanium oxide 1.5wt%.

[0072] (2) Dry pressing forming 12: a concave-convex mold w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com