A kind of marine ultra-high performance concrete and preparation method thereof

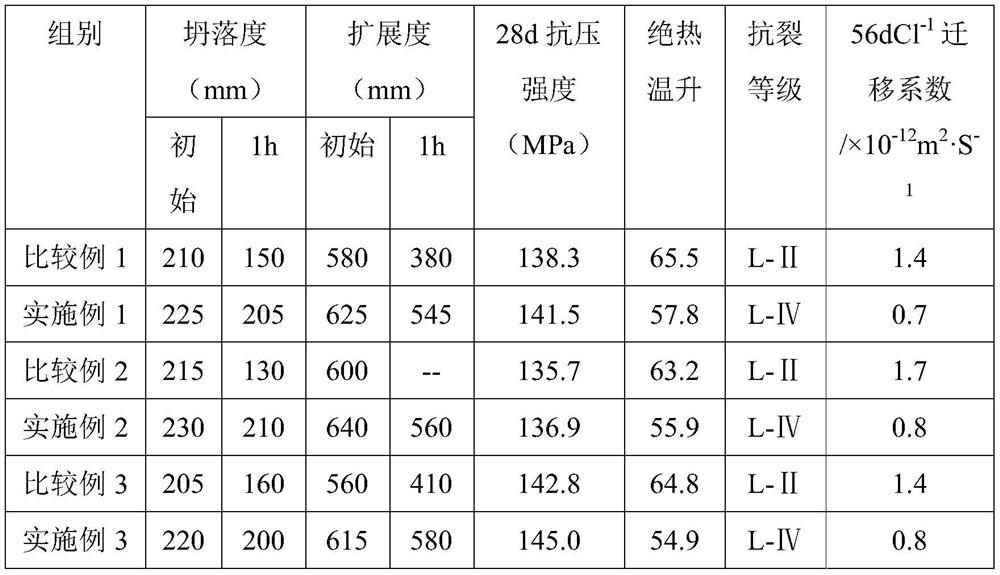

An ultra-high performance, concrete technology, applied in the field of building materials, can solve the problems that the mechanical properties cannot meet the engineering requirements, affect the durability of concrete, and is not suitable for large-scale pouring, etc., and achieve excellent resistance to chloride ion penetration, good flow performance and The effect of fluidity retention ability and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for preparing marine ultra-high performance concrete, comprising the following steps:

[0051] 1), weigh 280g of polycarboxylate high-performance water reducer, 105g of sodium lignosulfonate water reducer, 105g of melamine water reducer, 28g of sodium gluconate, 14g of sodium hexametaphosphate, 0.35g of defoamer and 260.0g of water g, stirred evenly, used as an admixture, for later use;

[0052] 2), the concrete mixing volume is 15L. Weigh 9.375kg of P.O42.5 cement, 1.5kg of fly ash, 1.5kg of mineral powder, 2.25kg of silica fume, 0.45kg of nano-silicon dioxide, 18.75kg of quartz sand, 0.525kg of steel fiber, 0.0075kg of polypropylene fiber, Hydration heat inhibitor 0.015kg, admixture 0.63kg, water 3.075kg for standby.

[0053] 3), add the cement, fly ash, mineral powder, silica fume, nano silicon dioxide, quartz sand, polypropylene fiber and heat of hydration inhibitor weighed in step 2) into the stirring pot and stir for 60 seconds, then stir While adding ...

Embodiment 2

[0057] A method for preparing marine ultra-high performance concrete, comprising the following steps:

[0058] 1) Weigh 350g of polycarboxylate high-performance water reducer, 70g of sodium lignosulfonate water reducer, 70g of melamine water reducer, 21g of sodium gluconate, 21g of sodium tripolyphosphate, 0.56g of defoamer, and 375.0g of water g, stirred evenly, used as an admixture, for later use;

[0059] 2), the concrete mixing volume is 15L. Weigh P.O 52.5 cement 8.25kg, fly ash 2.25kg, mineral powder 2.25kg, silica fume 1.5kg, nano-silicon dioxide 0.3kg, quartz sand 18kg, steel fiber 1.17kg, PP fiber 0.015kg, heat of hydration inhibitor 0.03kg, admixture 0.63kg, water 2.85kg for standby.

[0060] 3), add the cement, fly ash, mineral powder, silica fume, nano silicon dioxide, quartz sand, polypropylene fiber and heat of hydration inhibitor weighed in step 2) into the stirring pot and stir for 60 seconds, then stir While adding the weighed steel fiber, the feeding time ...

Embodiment 3

[0064] A method for preparing marine ultra-high performance concrete, comprising the following steps:

[0065] 1), weigh 360g of polycarboxylate high-performance water reducer, 18g of sodium lignosulfonate water reducer, 36g of calcium lignosulfonate water reducer, 30g of melamine water reducer, 30g of sodium gluconate, 12g of white sugar, Foaming agent 0.6g, water 300.0g, stir evenly, as admixture, spare;

[0066] 2), the concrete mixing volume is 15L. Weigh 7.2kg of P.Ⅱ52.5 cement, 3.0kg of fly ash, 3.0kg of mineral powder, 0.75kg of silica fume, 0.15kg of nano-silicon dioxide, 16.5kg of quartz sand, 2.34kg of steel fiber, 0.03kg of polypropylene fiber, Hydration heat inhibitor 0.045kg, admixture 0.56kg, water 2.775kg for standby.

[0067] 3), add the cement, fly ash, mineral powder, silica fume, nano silicon dioxide, quartz sand, polypropylene fiber, heat of hydration inhibitor weighed in step 2) into the stirring pot and stir for 60 seconds, then Add steel fiber while s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com