High-stability two-dimensional black phosphorene as well as preparation method and application thereof

A high-stability, black phosphorene technology, applied in the preparation of phosphorus, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as increasing stability and catalytic activity, and achieve improved stability, environmental friendliness, and treatment. mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Weigh 50 mg of bulk black phosphorus into a centrifuge tube, add 30 mL of liquid nitrogen, keep it for 30 minutes, disperse it in a mixed solution of 30 mL of IPA and 15 mL of water, and treat it with ultrasonic waves of 200 W for 3 hours at a water bath temperature of 5 °C. The above solution was centrifuged at 5000 rpm for 5 minutes, and the supernatant obtained by separation was a two-dimensional ultra-thin black phosphorus dispersion. Freeze-dry at minus 80°C to obtain two-dimensional ultra-thin black phosphorus powder.

Embodiment 2

[0030] Example 2: Weigh 100 mg of bulk black phosphorus into a centrifuge tube, add 40 mL of liquid nitrogen, keep it for 40 minutes, disperse it in a mixed solution of 40 mL of IPA and 30 mL of water, and treat it with 150 W ultrasonic wave for 4 hours, and the temperature of the water bath is 7 °C. The above solution was centrifuged at 5000 rpm for 5 minutes, and the supernatant obtained by separation was a two-dimensional ultra-thin black phosphorus dispersion. Freeze-dry at minus 70°C to obtain two-dimensional ultra-thin black phosphorus powder.

Embodiment 3

[0031] Example 3: Weigh 150 mg of bulk black phosphorus into a centrifuge tube, add 50 mL of liquid nitrogen, keep it for 60 minutes, disperse it in a mixed solution of 50 mL of IPA and 50 mL of water, and ultrasonically treat it for 5 hours at a water bath temperature of 0°C. The above solution was centrifuged at 5000 rpm for 5 minutes, and the supernatant obtained by separation was a two-dimensional ultra-thin black phosphorus dispersion. Freeze-dry at minus 70°C to obtain two-dimensional ultra-thin black phosphorus powder.

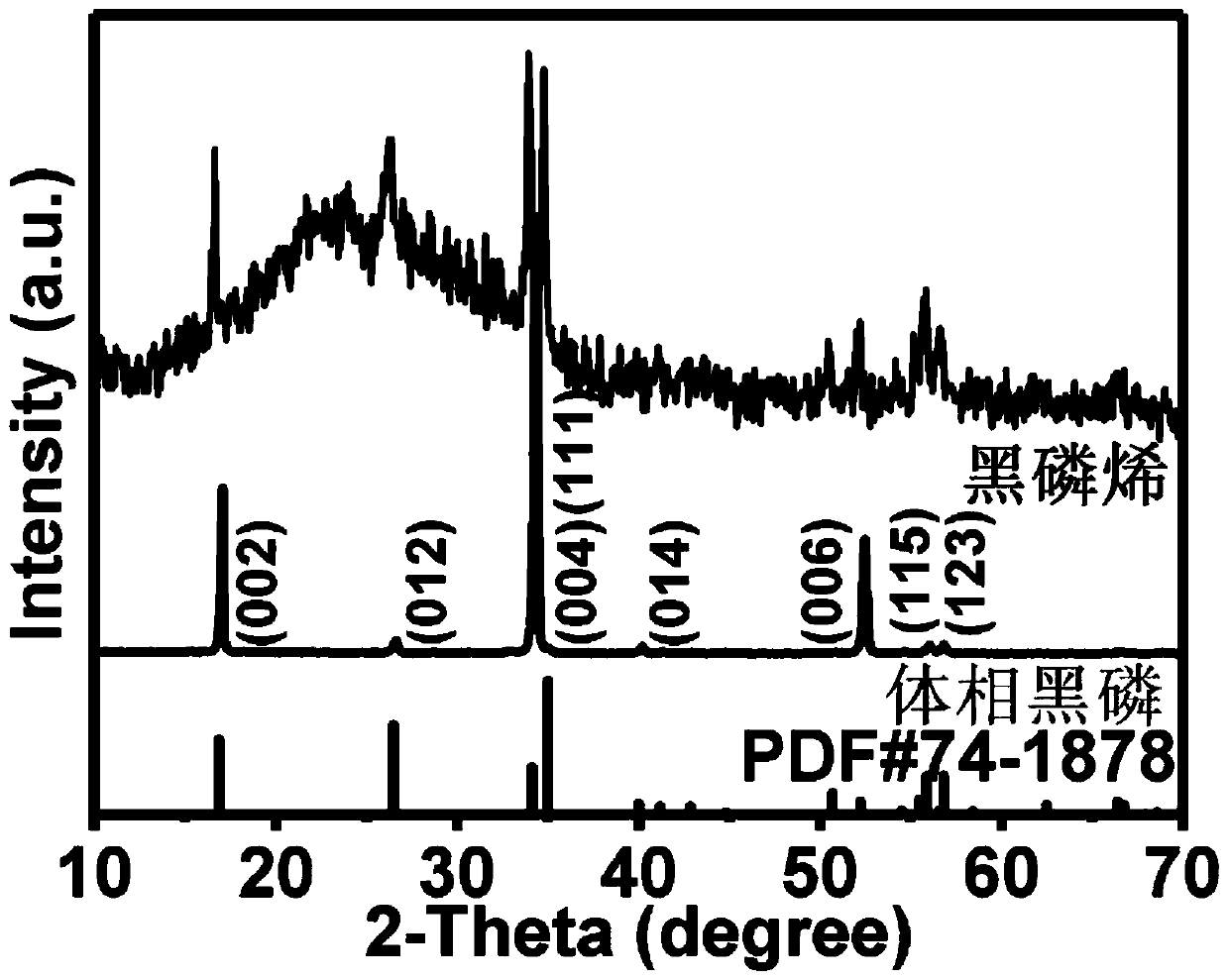

[0032] The structural test of the prepared sample was carried out on a German Bruker D8 type ray diffractometer (XRD) (Cu-Kα ray, The range is 10°-80°), and the scan rate is 7°min-1. like figure 1 As shown, all peaks of bulk black phosphorus and two-dimensional ultrathin black phosphorus obtained by ultrasonic liquid phase exfoliation can correspond to the standard XRD card of black phosphorus (JCPDS: 74-1872).

[0033] The two-dimensional ultrathin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com