Transport and dumping device

A technology of dumping device and conveying plate, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of large fluid flow resistance and leakage, high maintenance and use cost, limited application scope, etc., achieving long service life, convenient maintenance, Use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

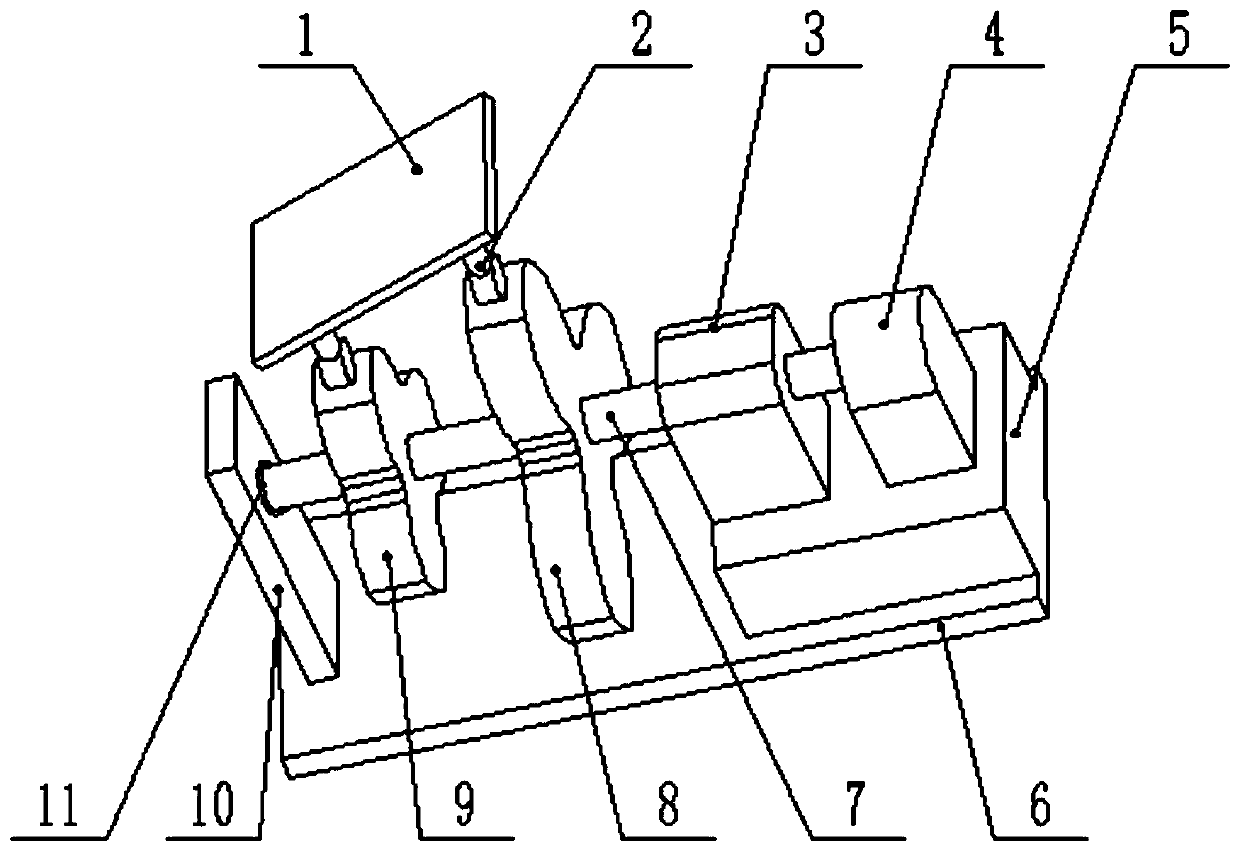

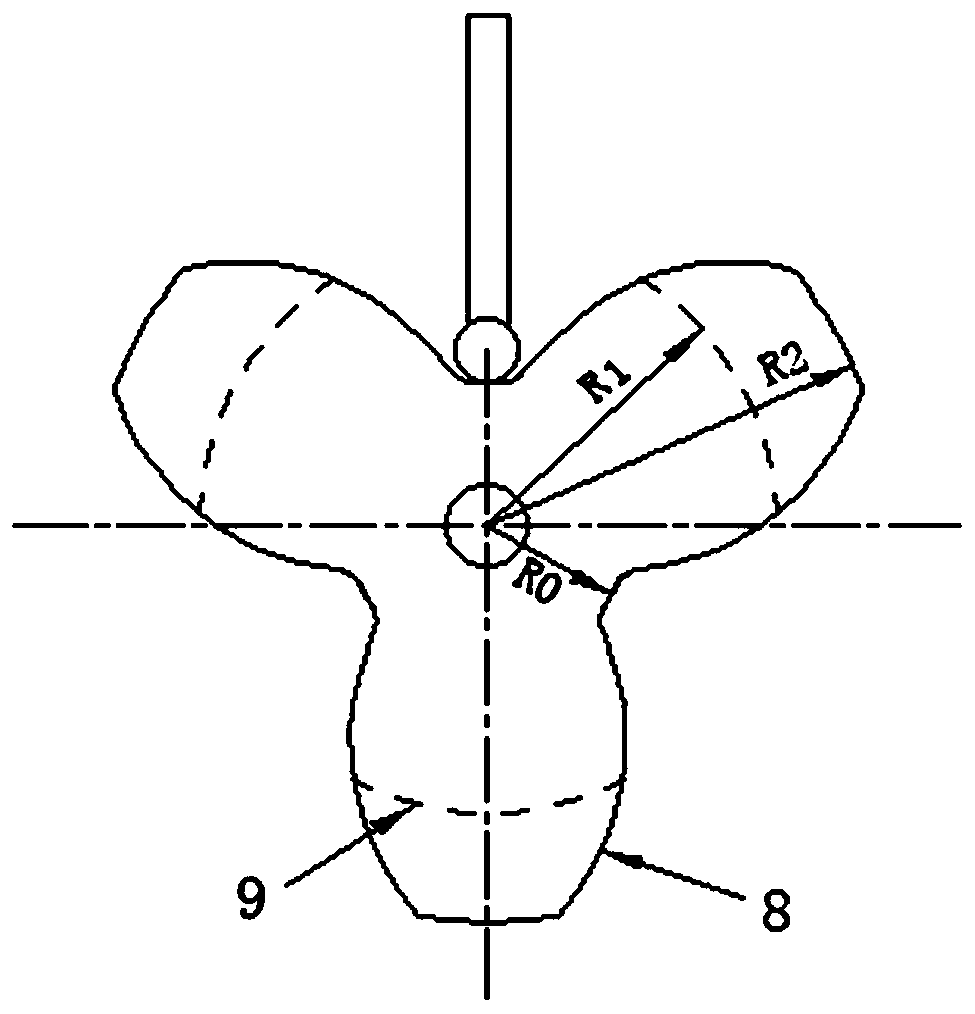

[0026] A transport dumping device, the structure of which is as figure 1 As shown, the device is mainly composed of three mechanisms: the frame, the power supply part and the rotating and lifting part. Wherein, the frame includes a base plate 6, a support plate 10 arranged on the base plate 6 and a motor seat 5, the support plate 10 is arranged on one side of the base plate 6, and the motor seat 5 is positioned at the other side of the base plate 6 relative to the support plate 10, for example , in this embodiment, the support plate 10 is arranged on the left side of the base plate 6 , and the motor seat 5 is located on the upper surface of the right side of the base plate 6 .

[0027] The power supply part includes a motor 4 and a gearbox 3 arranged on a motor seat 5 arranged on the base plate 6. The motor and the gearbox adopt backrest wheels or other connections, utilize the motor 4 to provide power, and utilize the gearbox 3 to change the output of power, thereby Change t...

Embodiment 2

[0045] A transport dumping device, the structure of which is roughly the same as that of Embodiment 1, the difference is that the middle part of this embodiment contains a motor seat, and the gearbox and the motor are directly installed on the bottom plate.

Embodiment 3

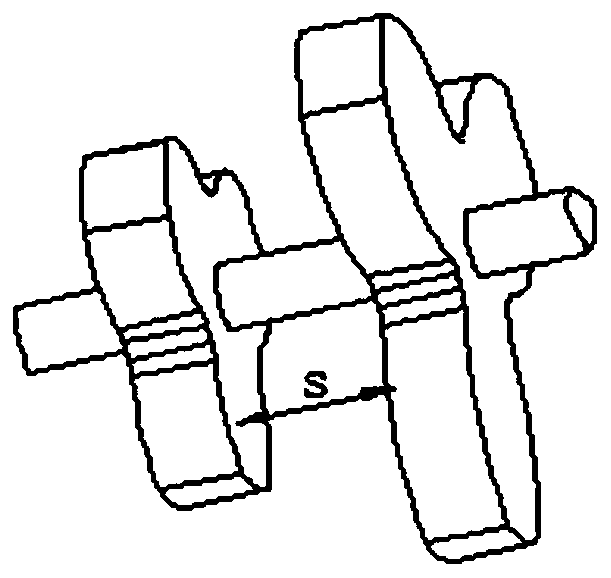

[0047] A transport dumping device, the structure of which is roughly the same as that of Embodiment 1, the difference is that three special-shaped wheels are provided in this embodiment, and the three special-shaped wheels are respectively connected to three rotating shafts, and each rotating shaft is arranged concentrically. Keep the RPM the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com