Dual-channel continuously variable transmission fuel vehicle power system

A technology of power system and continuously variable speed, which is applied in the direction of transmission, vehicle components, gear transmission, etc., and can solve the problems of affecting driving experience and acceleration lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

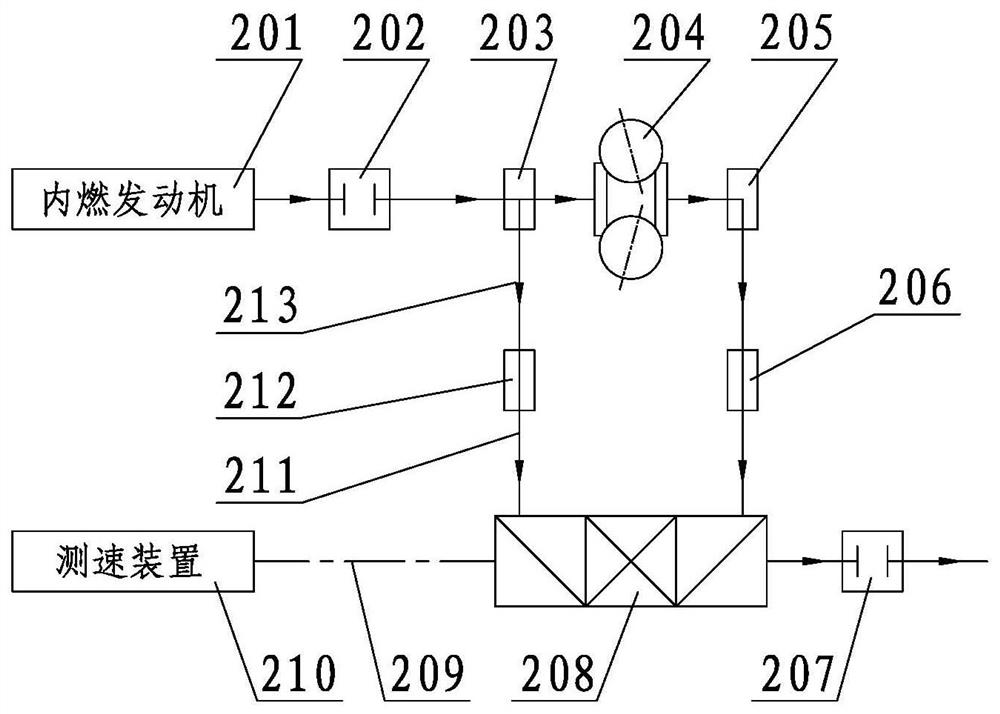

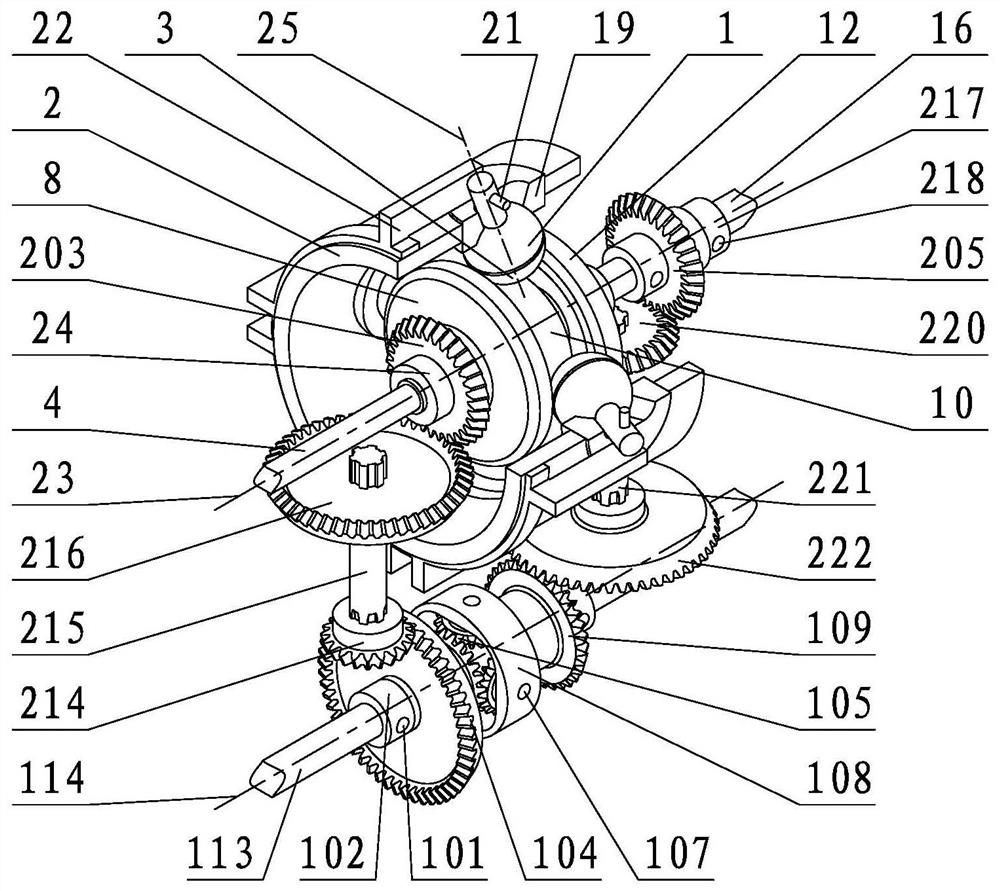

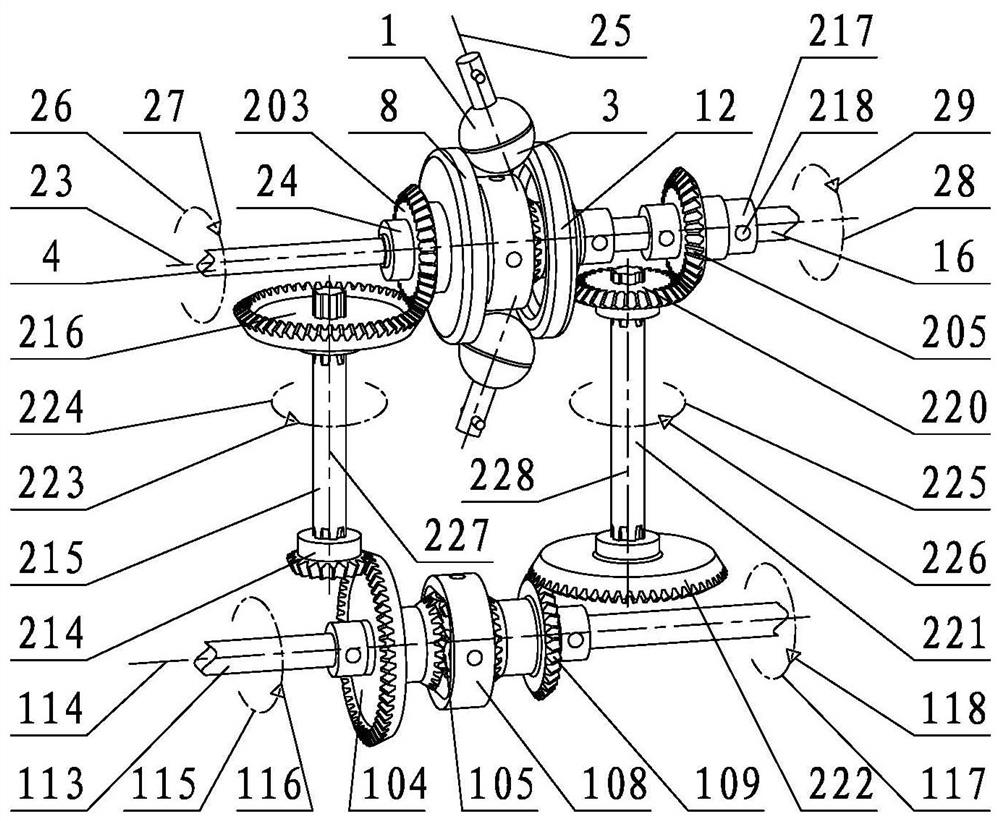

[0059] The present invention is further described below in conjunction with accompanying drawing. refer to Figure 1 to Figure 4 , Figure 15 , Figure 26 , the power system includes an internal combustion engine 201, a clutch one 202, a connecting gear two 203, a continuously variable transmission 204, a connecting gear one 205, a gear connecting part one 206, a clutch two 207, a final reducer 208, a speed measuring device 210, a gear connecting Part II 212. The continuously variable transmission 204 of the power system adopts a steel ball speed-adjusting bevel gear differential speed reduction mechanism, and the main reducer 208 adopts a double bevel gear differential speed reduction mechanism. The final reducer 208 includes double bevel gear one 109 and double bevel gear two 104, the main outer gear teeth one 122 of the double bevel gear one 109 is the input end one of the main reducer 208, and the main outer gear teeth two of the double bevel gear two 104 125 is the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com