Special forced stirrer for normal-temperature asphalt mixture

A technology for forced mixer and normal temperature asphalt, applied in mixers, mixer accessories, mixers with rotating mixing devices, etc., can solve problems such as stuck, difficult cleaning, incomplete mixing of mixing arms, etc., to improve the effect and prevent material The effect of depositing and improving the stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

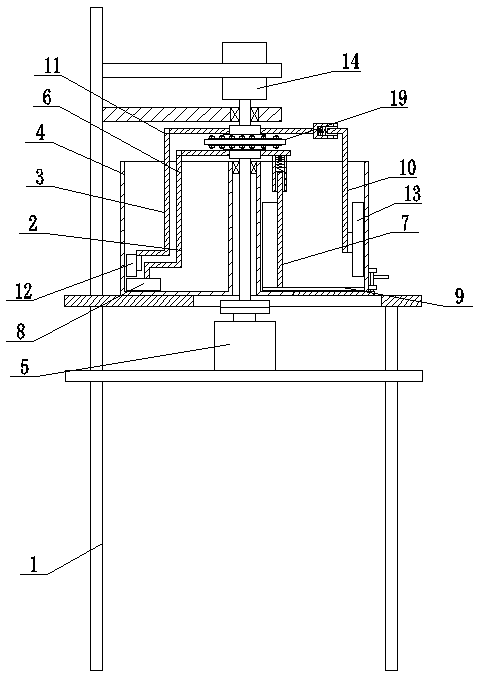

[0026] A special forced mixer for normal temperature asphalt mixture, which consists of: a mixer bracket 1 and a cylindrical mixing cylinder 4 fixed on the mixer bracket, a lower speed reduction motor 5 is fixed on the mixer bracket, and the lower speed reduction motor 5 is fixed on the mixer bracket. The output shaft of the motor passes through the center of the cylindrical mixing tank and is fixed to the mixing arm 2 at the bottom of the cylinder, and the upper part of the mixer bracket is fixed to the upper reduction motor 14, and the output shaft of the upper reduction motor is connected to the side wall mixing arm 3 fixed;

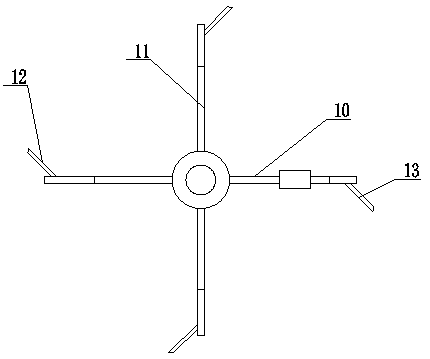

[0027] The cylinder bottom stirring arm includes a group of bottom non-contact support arms 6 and a bottom contact support arm 7, the bottom non-contact support arm bottom fixes the bottom non-contact scraper 8, and the bottom contact The bottom contact scraper 9 is fixed on the support arm, and the tank bottom stirring arm stirs the bottom of the tan...

Embodiment 2

[0030] According to the special forced mixer for normal temperature asphalt mixture described in Example 1, the bottom contact scraper is L-shaped.

Embodiment 3

[0032] According to the special forced mixer for normal temperature asphalt mixture described in embodiment 1 or 2, both the bottom contact connecting arm and the side contact connecting arm include a first connecting arm 15 and a second connecting arm 18, and the A sleeve 17 is fixed on the first connecting arm, and a spring 16 is arranged in the sleeve and connected with the second connecting arm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com